High Efficiency Ultrasonic Coating Machine Ultrasonic Spray Nozzle with Uninterrupted Liquid Supply System

What's ultrasonic spray nozzle?

An ultrasonic spray nozzle, also known as an ultrasonic atomizer, is a device that utilizes ultrasonic vibrations to generate a fine spray or mist of liquid droplets. It is commonly used in applications such as coating, humidification, fuel injection, and chemical reactions.

Here's how an ultrasonic spray nozzle typically works:

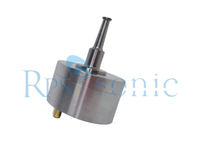

1. Ultrasonic transducer: The core component of an ultrasonic spray nozzle is an ultrasonic transducer. It usually consists of a piezoelectric element, such as a piezoceramic disk, that can convert electrical energy into mechanical vibrations. When an alternating current (AC) voltage is applied to the piezoelectric element, it causes it to vibrate at ultrasonic frequencies,typically in the range of 1 to 100 megahertz (MHz).

2. Liquid supply: The liquid to be sprayed is supplied to the ultrasonic spray nozzle. It can be a solution, suspension, or any

other liquid that needs to be atomized into small droplets.

3. Vibrating plate: The ultrasonic transducer is coupled to a vibrating plate or diaphragm. This plate is typically made of a

thin metal or ceramic material and acts as a surface for the liquid to rest upon.

4. Cavitation and atomization: As the ultrasonic transducer vibrates, it induces high-frequency pressure waves in the liquid resting on the vibrating plate. These pressure waves create microscopic cavitation bubbles in the liquid. Cavitation is the rapid formation and collapse of bubbles in a liquid due to pressure changes. When the bubbles collapse, they generate localized shockwaves and intense energy. This energy disrupts the liquid surface, causing it to break up into small droplets.The size of the droplets can be controlled by adjusting the parameters of the ultrasonic vibrations.

5. Spray formation: The liquid droplets generated by the cavitation process are then expelled from the ultrasonic spray nozzle as

a fine mist or spray. The spray can be directed to a specific target or area as required.

Parameter:

| Item | Parameter |

| Frequency | 40Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~40ml/min |

| Spray width | 5~25mm |

| Solution utilization | above 98% |

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Application:

Electronics: Sensors, PCB Fluxing, Semiconductors etc.

Industrial: Glass, Touch Screen, etc.

Medical: Stents, Balloon Catheters, Diagnostic Device etc.

Energy: Fuel Cell, Solar Cell, etc.