Ultrasonic Machining Hard And Brittle Materials hole Drilling

Introduction

In contrast, ultrasonic machining is a non-thermal, non-chemical and non-electrical machining process that leaves the chemical composition, material microstructure and physical properties of the workpiece unchanged. Sometimes referred to as ultrasonic impact grinding (UIG) or vibration cutting, the UM process can be used to generate a wide range of intricate features in advanced materials.

UM is a mechanical material removal process that can be used for machining both conductive and non-metallic materials with hardnesses of greater than 40 HRC (Rockwell Hardness measured in the C scale). The UM process can be used to machine precision micro-features, round and odd-shaped holes, blind cavities, and OD/ID features. Multiple features can be drilled simultaneously, often reducing the total machining time significantly .

High-frequency, low-amplitude energy is transmitted to the tool assembly. A constant stream of abrasive slurry passes between the tool and workpiece. The vibrating tool, combined with the abrasive slurry, uniformly abrades the material, leaving a precise reverse image of the tool shape. The tool does not come in contact with the material; only the abrasive grains contact the workpiece.

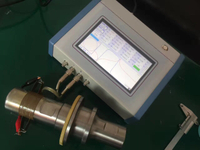

In the UM process, a low-frequency electrical signal is applied to a transducer, which converts the electrical energy into high-frequency (~20 KHz) mechanical vibration (see Figure 2). This mechanical energy is transmitted to a horn and tool assembly and results in a unidirectional vibration of the tool at the ultrasonic frequency with a known amplitude. The standard amplitude of vibration is typically less than 0.002 in. The power level for this process is in the range of 50 to 3000 watts. Pressure is applied to the tool in the form of static load.

A constant stream of abrasive slurry passes between the tool and the workpiece. Commonly used abrasives include diamond, boron carbide, silicon carbide and alumina, and the abrasive grains are suspended in water or a suitable chemical solution. In addition to providing abrasive grain to the cutting zone, the slurry is used to flush away debris. The vibrating tool, combined with the abrasive slurry, abrades the material uniformly, leaving a precise reverse image of the tool shape.

Ultrasonic machining is a loose abrasive machining process that requires a very low force applied to the abrasive grain, which leads to reduced material requirements and minimal to no damage to the surface. Material removal during the UM process can be classified into three mechanisms: mechanical abrasion by the direct hammering of the abrasive particles into the workpiece (major), micro-chipping through the impact of the free-moving abrasives (minor), and cavitation-induced erosion and chemical effect (minor).2

Material removal rates and the surface roughness generated on the machined surface depend on the material properties and process parameters, including the type and size of abrasive grain employed and the amplitude of vibration, as well as material porosity, hardness and toughness. In general, the material removal rate will be lower for materials with high material hardness (H) and fracture toughness (KIC).

Parameters of Ultrasonic Machining:

The ultrasonic vibration machining method is an efficient cutting technique for difficult-tomachine materials. It is found that the USM mechanism is influenced by these important parameters.

Amplitude of tool oscillation(a0)

Frequency of tool oscillation(f)

Tool material

Type of abrasive

Grain size or grit size of the abrasives – d0

Feed force - F

Contact area of the tool – A

Volume concentration of abrasive in water slurry – C

Ratio of workpiece hardness to tool hardness; λ=σw/σt

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

Although manufacturing technologies are well developed for materials like metals and their alloys, considerable problems still exist in the fabrication of hard and brittle materials including ceramics and glass. Their superior physical and mechanical properties lead to long machining cycle and high production cost. Ultrasonic machining (USM) using loose abrasive particles suspended in a liquid slurry for material removal is considered an effective method for manufacturing these materials. This work gives a brief overview of USM first and then mainly addresses the development of a simulation model of this process using a mesh-free numerical technique, the smoothed particle hydrodynamics (SPH). The crack formation on the work surface impacted by two abrasive particles is studied for understanding the material removal and the interaction of abrasive particles in USM. Experiments are also conducted to verify the simulation results. The SPH model is proven useful for studying USM and is capable of predicting the machining performance.

Hard and brittle materials, such as glass, ceramics, and quartz crystal, are getting more and more attention in the recent years due to their superior properties like high hardness, high strength, chemical stability, and low density. High-performance products made of these materials play an important role in various industrial fields including semiconductor, optical components, aerospace, and automotive industries [1, 2]. However, considerable problems such as long machining cycle and high production cost still exist in the fabrication of hard and brittle materials. Particular difficulties are the production of micro−/nanostructures with high machining efficiency, high aspect ratios, and good surfaces possessing no residual stress and microcracks. Hence, there is a crucial need for developing precision and efficient micromachining techniques for these materials.

Nontraditional machining techniques such as electric discharge machining and laser beam machining have been proposed to machine hard and brittle materials. However, even these processes have prominent limitations that the machined surfaces are always subjected to heat-induced damages like recast layer and thermal stress. Ultrasonic machining (USM) is another alternative method for manufacturing both conductive and nonconductive hard and brittle materials. It is known as a total mechanical process without suffering from heat or chemical effects, so USM would not thermally damage the machining objects or appear to cause significant levels of residual stress and chemical alterations.