1. Set-up: The workpiece, which may be a metal component or structure, is prepared for the ultrasonic stress relief process. This may involve cleaning the surface, ensuring proper fixturing, and determining the appropriate parameters for the specific material and application.

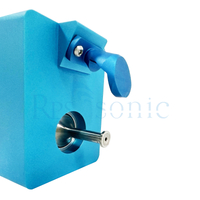

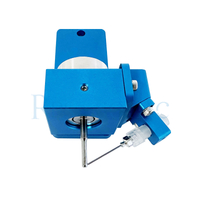

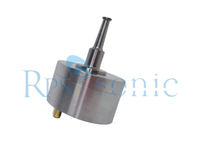

2. Ultrasonic Vibration Application: A specialized ultrasonic stress relief equipment is used to apply high-frequency vibrations to the workpiece. The vibrations are typically in the range of 20 kHz to 100 kHz and are applied using

an ultrasonic transducer. The transducer generates mechanical vibrations that are transmitted to the workpiece through a contact medium,such as a tool or horn.

3. Vibration Distribution: The ultrasonic vibrations are directed to specific areas of the workpiece where residual stresses are concentrated. The vibrations penetrate the material, causing microstructural changes and redistributing the stress patterns.The high-frequency vibrations induce plastic deformation in the material, promoting stress relaxation.

4. Stress Relief: The ultrasonic vibrations help to dislodge and rearrange dislocations in the material's microstructure. This

process leads to the reduction of residual stresses within the workpiece. The redistributed stresses result in a more uniform stress distribution, which can improve the material's fatigue resistance, dimensional stability, and overall structural integrity.

5. Process Optimization: The parameters of the ultrasonic stress relief process, such as vibration frequency, amplitude, and duration, may be adjusted to optimize the stress relief effect. The specific parameters depend on factors such as the material type, thickness, and desired stress relief outcome..