Medical balloon catheter spraying technology is a key process in the manufacturing of medical devices. It is mainly used to coat drugs (such as anti-proliferative drugs), lubricating coatings or developing marks on the surface of the balloon to enhance the therapeutic effect and operational performance. Technologies such as ultrasonic spraying and electrostatic spraying are widely applied in this field. The following is the detailed analysis:

I. Core Requirements for Medical balloon Catheter Spraying

Functional coating

Drug coatings: such as paclitaxel and rapamycin (used in angioplasty to inhibit restenosis).

Lubricating coating: Hydrophilic coating (reducing friction between the catheter and the vessel wall).

Developing coating: Containing barium/bismuth compounds (for easy X-ray positioning).

Process requirements

Uniformity: The thickness error of the coating should be less than 5% (especially for drug coatings).

Biocompatibility: Non-toxic, does not cause thrombosis or inflammation.

Adhesion force: Resistance to mechanical stress during blood flow scouring and balloon expansion.

Ii. Comparison of Mainstream Spraying

Technologies Ultrasonic spraying, electrostatic spraying, dip coating/rotary coating

Principle high-frequency ultrasonic atomization + carrier gas injection, the electric field causes the charged coating to adsorb onto the surface of the balloon, physical impregnation + centrifugal drying

Precision Ultra-high (layer thickness controllable from 0.1 to 10μm), High (conductive substrate required), Low (edge prone to accumulation)

Applicable materials: drug solutions and polymer colloids, conductive coatings or solvent-based coatings, high-viscosity coatings

Uniformity: Best (CV<3%), good (CV<8%), average (CV>15%)

Representative application: Drug-eluting balloon (DEB) metal stent-coated balloon development marking

Iii. Technical Details of Ultrasonic Spraying in Balloon Catheters

1. Process flow

Pretreatment: Plasma cleaning (to enhance surface energy and strengthen adhesion).

Atomization spraying

The drug solution is atomized into particles of 5 to 20μm through ultrasonic nozzles.

The balloon rotates (200-500rpm) while moving axially to achieve spiral coverage.

Drying and curing: Low-temperature drying (to prevent drug denaturation) or UV curing (for polymer coatings).

2. Key parameter control

Frequency selection: 80-120kHz (to balance atomization fineness and output).

Carrier gas pressure: 0.05-0.2MPa (to prevent excessive diffusion from causing coating blurring).

Solution concentration: It needs to match the surface tension (for example, paclitaxel is commonly 0.5-1.0μg/mm²).

3. Advantages

Non-clogging: Suitable for suspensions containing particles (such as drug-carrier microspheres).

Low-temperature operation: Protect the activity of heat-sensitive drugs.

Complex shape adaptation: The pleated area of the balloon in the folded state can be sprayed.

Iv. Industry Application Cases

Drug-eluting Balloon (DEB

Case: Boston Scientific's Ranger™ DCB uses ultrasonic spraying of paclitaxel + carrier polymer, with a coating uniformity of ±2%.

Challenge: The drug release kinetics needs to be matched with the coating structure (such as multi-layer spraying controlled sustained-release).

Hydrophilic coated balloon

Material: Polyacrylic acid /PVP composite solution.

Process: After ultrasonic spraying, γ -ray sterilization is carried out, and the lubricity is maintained at >90% (the guide wire passes the test).

Spraying of development marks

Innovation: Terumo's nano-bismuth coating, ultrasonic atomization makes the width of the developing point less than 0.3mm.

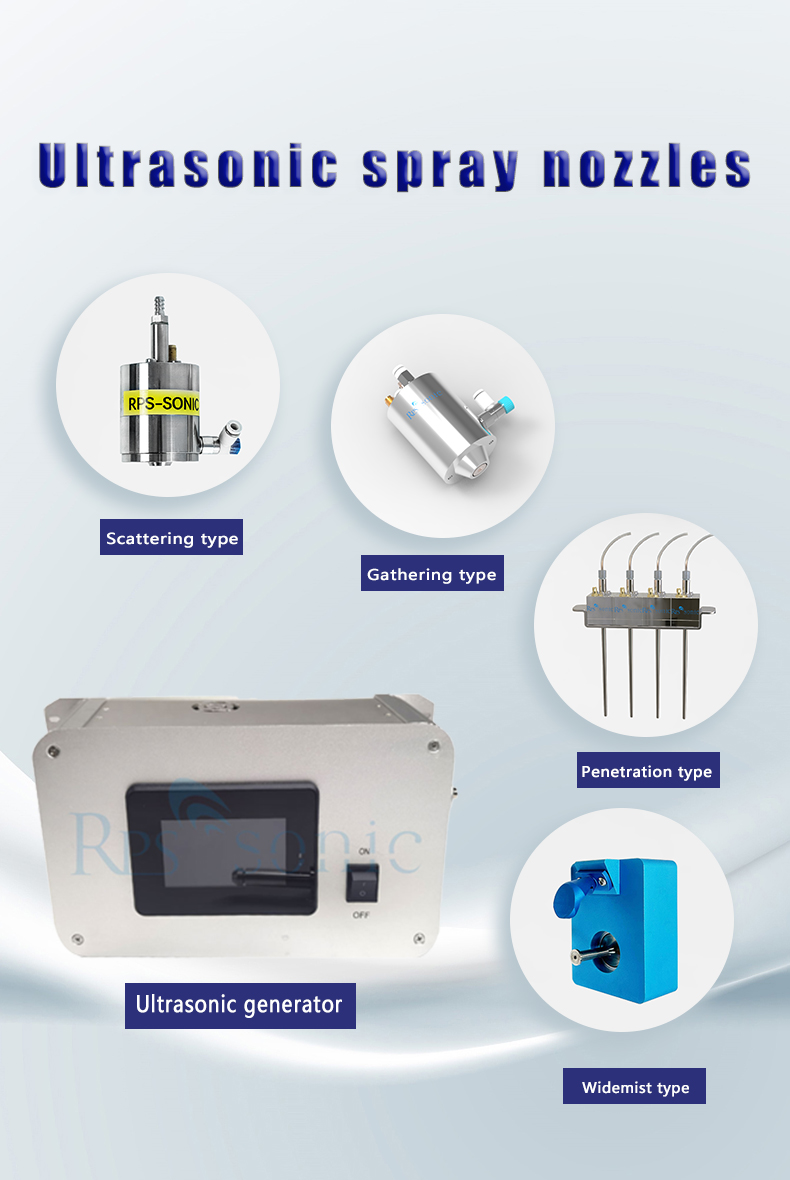

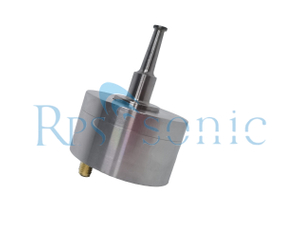

Ultrasonic atomizing nozzles and our subcutaneous delivery of drug-evading chemicals can effectively achieve continuous and uniform coated balloon catheters.

The RPS-SONIC ultrasonic spray nozzle minimizes product caking or material agglomeration. Our technology will not cause excessive exposure to the atmosphere during application, nor will it shear and separate the materials in the suspension, thereby not damaging medical chemistry.

Ultrasonic nozzles not only have several key advantages in balloon catheter coating, but also have key advantages in dozens of precision medical device coating applications, including stents, guide wires, diagnostic equipment, blood collection tubes, orthopedic implants, implants, carbon nanotube deposition coatings and other materials that require thin film coatings. The inherent advantages of the ultrasonic atomizer nozzle endow it with greater process control capabilities, allowing it to control the solution flow rate, spray speed and droplet size, and the distribution range is narrower. The nozzle does not clog and has repeatable performance, which can reduce the use of spray materials by up to 80%.

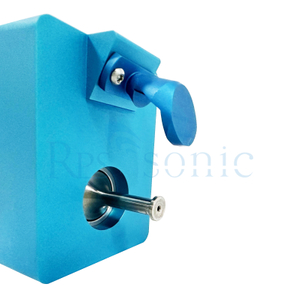

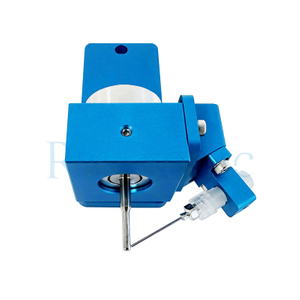

The RPS-SONIC medical balloon catheter coating system has a mandrel up to 2 meters long during the film coating process to keep the catheter straight. Typical solvents: THF, acetone, DMAC, toluene, chloroform; Polymers: Polyurethane, polycarbonate, silicone and styrene can be used in this system.