Most of the effective ingredients in plants exist in cells. How to extract them efficiently and apply them to industries such as biomedicine and food chemicals. This is one of the research hotspots of scientific research topics at this stage. Exploring advanced extraction processes and developing efficient plant extraction equipment are the key to studying the extraction of effective ingredients in plants.

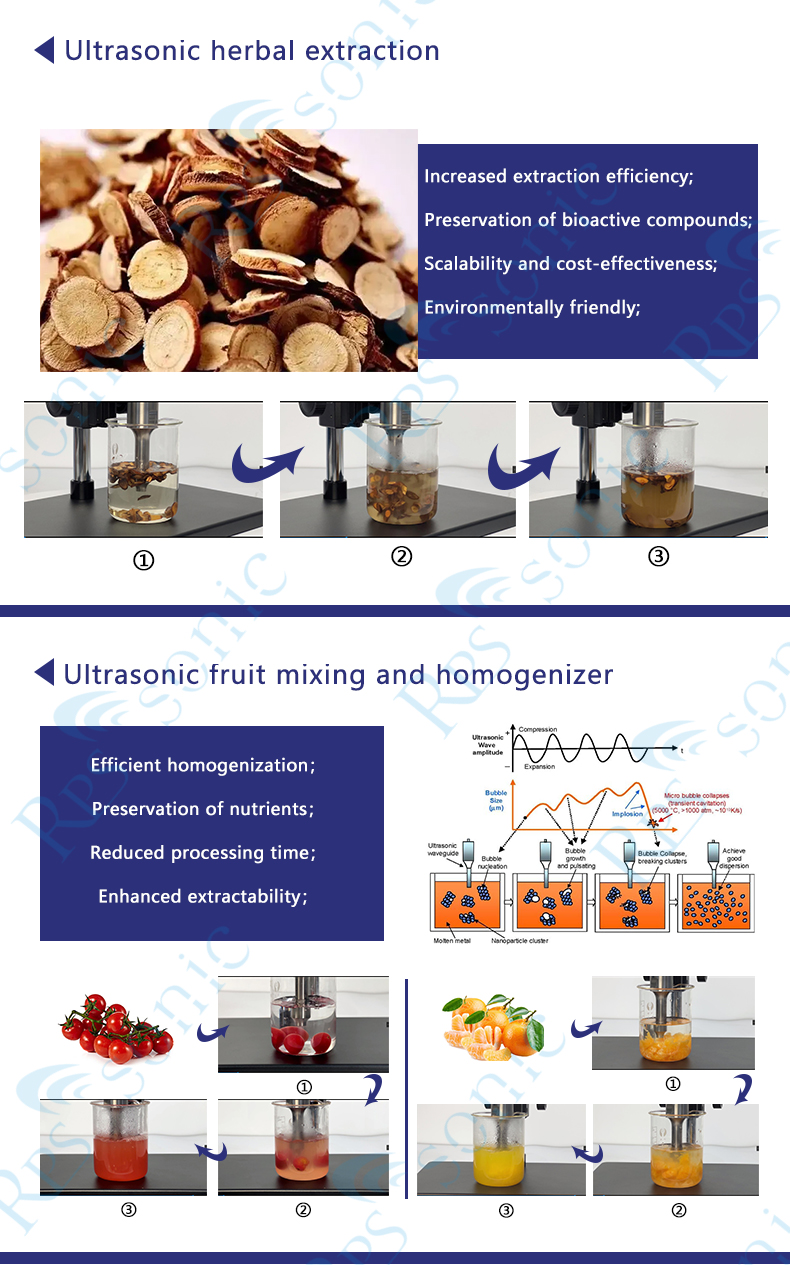

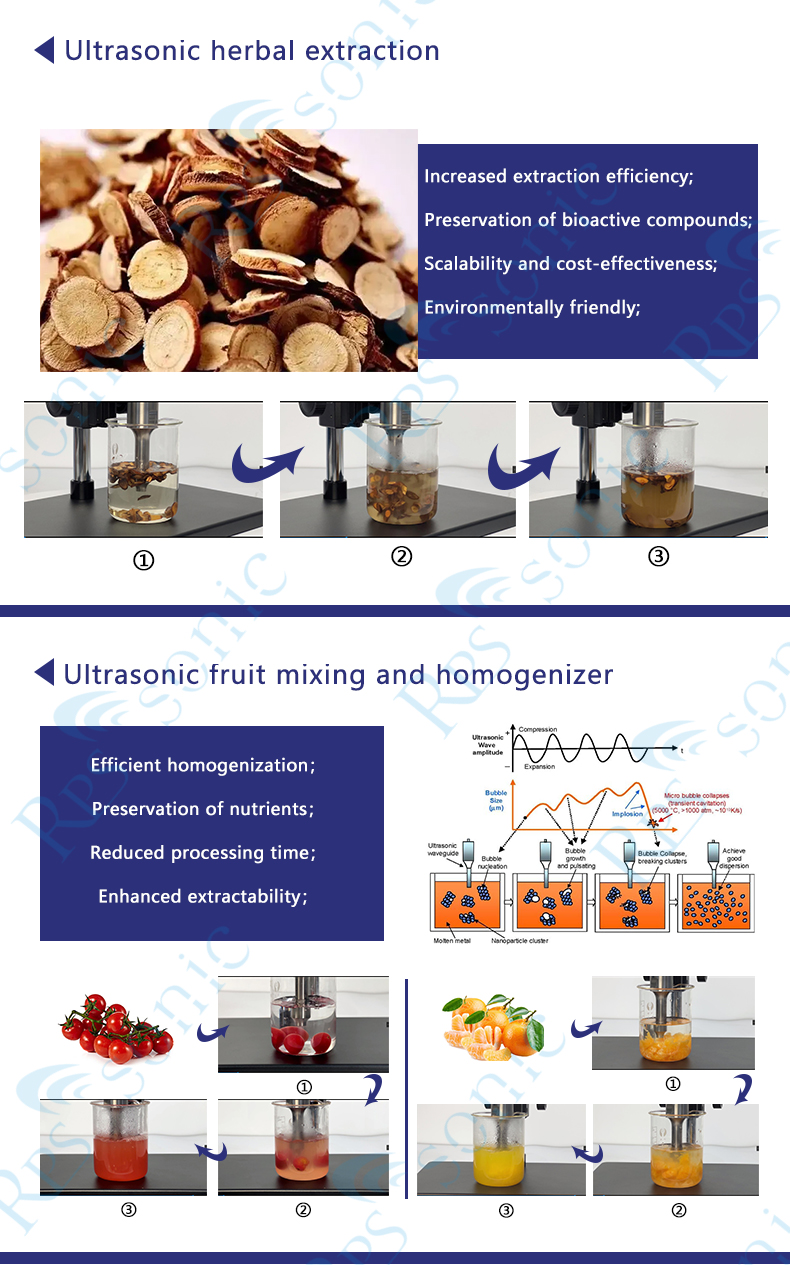

Ultrasonic disruption is an effective method for disrupting cells or organelles. Its mechanism is the cavitation phenomenon from bubble generation, growth, to bubble fragmentation when ultrasound acts on the solution. The shock wave and shear force caused by the cavitation phenomenon cause the cells to lyse, and the effective ingredients in the cells are instantly released into the solvent, thereby improving the extraction efficiency and shortening the extraction time. The use of ultrasonic disruption technology for plant extraction has the characteristics of fast extraction speed, high extraction rate, and good selectivity. Moreover, ultrasonic extraction has the advantages of large one-time processing volume, good repeatability, and simple operation. Therefore, ultrasonic extraction technology is widely used in the extraction of effective ingredients in plants. This technology has achieved certain results and played an important role in the field of plant extraction.

Development of ultrasonic-assisted plant extraction equipment

Laboratory-scale ultrasonic extraction equipment mainly includes water bath ultrasonic extractors and probe ultrasonic extractors, namely ultrasonic cleaners and ultrasonic cell crushers. The ultrasonic transducer of the ultrasonic cleaner is adsorbed on the bottom of the stainless steel bath. Its characteristic is that it uses a combination of multiple transducers to work, and the total ultrasonic power can be relatively large, but the power per unit volume is small. The probe transducer of the ultrasonic cell crusher can be inserted into any required extraction container. Its characteristic is that it uses a single high-power ultrasonic transducer, which is focused to make the power per unit volume larger, but the total power is relatively small. The extraction effect of the probe ultrasonic extractor is better than that of the water bath ultrasonic extractor.

The existing plant extraction equipment in China is all industrial production type, and the extraction tank capacity is large, which is not suitable for teaching and scientific research. Through the investigation, we understand the current status and development trend of plant active ingredient extraction technology and equipment at home and abroad. In view of the specific situation and actual needs of the School of Chemical Engineering of Huaqiao University, we designed an extraction tank that combines external heating circulation, ultrasonic crushing and electric stirring devices in combination with existing conditions and equipment resources, and produced a probe-type ultrasonic assisted plant extraction equipment system consisting of a heating device, an extraction device and a control device. The design of the extraction tank is the key to the development of this equipment.

1.1 Heating device

Most of the commercially available probe-type ultrasonic extraction equipment uses air bath heating and constant temperature. The heating temperature is uneven and not easy to maintain stability. It is very easy to cause local overheating, coking, and bonding, which greatly affects the quality of the extract and the efficiency of plant extraction. A super constant temperature water bath is used for external heating, and a water bath circulation pump is used to introduce hot water into the jacket of the extraction tank to heat the material in the extraction tank, so that the material heats up quickly and is constant at the required extraction temperature; thereby avoiding the phenomenon of coking and nuclear change caused by direct contact between the solid material in the extraction tank and the heating cylinder wall and bottom.

1.2 Extraction device

Compared with the traditional static extraction tank or the extraction tank with stirring, this extraction equipment combines the ultrasonic device and the electric stirring device, which not only simplifies the equipment and saves space, but also utilizes the synergistic effect of the advanced process of ultrasonic extraction and electric stirring to make the material evenly heated, avoiding the destruction of the activity of the heat-sensitive extract due to excessive local temperature, thereby ensuring the quality of the extract.

The extraction tank in this article is made of stainless steel, and the tank body adopts a jacketed cylindrical barrel design with a barrel diameter of 20cm, a height of 50cm, a diameter-to-height ratio of 2:5, and a volume of about 15L. The top cover of the extraction tank is designed with an ultrasonic probe insertion hole (40) and an electric stirrer stirring rod access port (26). At the same time, a temperature detector connecting tube, a sampling tube and a venting tube (interfaces with a diameter of 10 each) are designed to monitor the extraction temperature and extraction effect in real time. The extraction tank has a small capacity, a simple structure, and is easy to operate. It is suitable for experimental teaching and scientific research experiments.

1.3 Control device

The synergistic effect of the super constant temperature water bath and the circulating water pump is used to achieve automatic control of the circulating temperature of the extract; the automatic step-by-step collector and the circulating pump system are used to automatically sample the extract, so as to monitor the extraction process parameters and ensure the extraction efficiency.

2 Composition and working principle of the equipment system

The extraction equipment system in this paper mainly includes super constant temperature water bath, plant extraction tank, ultrasonic cell crusher, electric stirrer, automatic partial collector and other components.

The equipment system uses ultrasonic extraction technology for plant extraction. Its working principle is to use the cavitation phenomenon, mechanical action and thermal effect of ultrasound to promote the rapid release of the effective ingredients of the extract into the solvent to achieve the purpose of rapid extraction. The efficiency of ultrasonic crushing depends on the sound frequency, sound energy, processing time, cell concentration and cell type.

During the working process of the equipment system, a super constant temperature water bath is used to heat and accurately control the required extraction temperature. The pre-heated water bath is introduced into the jacket of the extraction tank, and the material is quickly heated and automatically controlled by the circulating water bath. Since the water bath temperature has a wide controllable range, it is more suitable for low-temperature extraction of natural products. The jacketed stainless steel extraction tank design is adopted, and the material is heated by the jacketed water bath, which is conducive to uniform heating of the material and avoids local coking. By adding an ultrasonic probe to the top of the tank and using an ultrasonic cell crusher for ultrasonic extraction, the extraction efficiency of the plant's active ingredients can be greatly improved. At the same time, an electric stirrer is added to the extraction tank to continuously stir and turn the material in the extraction tank, which is conducive to improving the extraction efficiency. An automatic partial collector is used to set time-division sampling, analyze the active ingredients of the plant, monitor the extraction effect, and make the extraction process controllable in real time.

3 Characteristics of plant extraction equipment system

1) This equipment system adopts an extraction tank design that combines external water bath circulation heating, ultrasonic crushing and electric stirring device. It has the advantages of high thermal efficiency, low energy consumption, good extract quality and high extraction rate. It solves the problems of low extraction efficiency, long extraction time, low yield and high energy consumption in traditional extraction methods such as extraction, pressing, extraction and reflux extraction.

2) The small ultrasonic extraction equipment currently sold on the market is generally expensive, with the lowest price of 50,000 yuan per unit. In addition, they all use air baths to heat the materials, and the stability cannot be guaranteed; or because the extraction tank is large in size and capacity (more than 40L), it occupies a lot of space and uses a lot of materials, which is not suitable for laboratory use. The extraction tank of this extraction equipment system is small in size, simple in structure, and easy to operate. It is more suitable for experimental teaching and scientific research experiments, reflecting the advantages of low price and good quality.

3) Utilizing the original super constant temperature water bath, ultrasonic cell crusher, automatic step collector and peristaltic pump and other equipment resources, and using some accessories such as waste electric stirrers, after processing, transformation, combination and matching, this extraction equipment system is designed and manufactured; it not only achieves the purpose and requirements of the design, but also makes full use of the effective value of waste equipment, saves experimental funds and increases investment.

Conclusion

The external heating circulation system combined with ultrasonic assisted technology is used to design and manufacture experimental equipment suitable for the extraction of effective components of natural products, achieving the goals of improving thermal efficiency, accelerating extraction speed and increasing extraction rate. It has been actually applied to the tea polyphenol extraction experiment in tea, and has achieved good results and has certain practical value. It is expected that this equipment system will have broad application prospects in the extraction of polysaccharides, polyphenols, and flavonoids from plants.

English

English