PEM electrolyzer hydrogen production is a type of water electrolysis hydrogen production technology with the advantages of high efficiency, no alkali, small size, safety and reliability, and good dynamic response. The proton exchange membrane electrolyzer (PEM) is mainly composed of membrane electrode (proton exchange membrane, catalyst layer, diffusion layer), bipolar plate, epoxy resin plate and end plate. Since the PEM electrolyzer uses perfluorosulfonic acid membrane, the working environment is acidic, and the high voltage and oxygen release on the anode side form an easily oxidized environment, the bipolar plate, gas diffusion layer and other structures of the PEM electrolyzer should have strong corrosion resistance. In order to increase the service life of the titanium felt of the gas diffusion layer of the PEM electrolyzer, its surface needs to be coated, and conductive anti-corrosion coatings such as platinum, iridium, gold, and carbon-based are usually used.

Ultrasonic spraying equipment is used in many electrolytic coating applications. The high uniformity of the catalyst layer and the uniform dispersion of suspended particles can create very efficient electrolyzer coatings, whether single-sided or double-sided. In green hydrogen production, hydrogen is produced by electrolytic decomposition of water, producing only hydrogen and oxygen. Ultrasonic spray equipment coats the electrolyzer in this truly green energy production process.

Ultrasonic spray equipment has proven to be ideal for coating PEM electrolyzers in high-volume hydrogen fuel cell production, and is ideal for spraying carbon-based catalyst inks onto electrolyte membranes. Ultrasonic spray equipment is fully automated, capable of double-sided coating, and able to apply different catalyst formulations to each side of the membrane. The durability and repeatability of the coatings have been shown to be superior to other coating methods, often providing not only longer life of the coated PEM, but also higher efficiency.

In carbon capture electrolysis applications, ultrasonic coating equipment applies catalysts to membranes used to separate and capture carbon dioxide before it enters the atmosphere. Carbon dioxide is separated from other gases in exhaust streams produced by industrial processes, such as those from coal and natural gas power plants or steel and cement plants; with the goal of reducing carbon emissions to combat global warming. Typically, the captured carbon dioxide can be processed into valuable carbon-based byproducts such as plastics, rubber or fuels.

Advantages of ultrasonic spraying for preparing hydrogen electrolyzer coatings:

1. High spraying uniformity: Ultrasonic spraying technology can make the liquid distribute on the electrode surface in an extremely uniform manner, and the coating is smooth and uniform, which can avoid the accumulation of thick and excessive coatings and affect the coating surface;

2. Accurate control of coating thickness: Ultrasonic spraying technology can achieve precise coating thickness control. Since this technology can accurately control the coating time and the spray speed of the coating solution, it can well control the coating thickness;

3. High coating quality: Ultrasonic spraying technology can produce ultrafine droplets and atomize them. Compared with conventional spraying, the droplets produced are more uniform. It can provide higher coating quality and more uniform coating surface, and has been widely used in many fields such as batteries and solar cells.

RPS-SONIC Ultrasonic spraying equipment features:

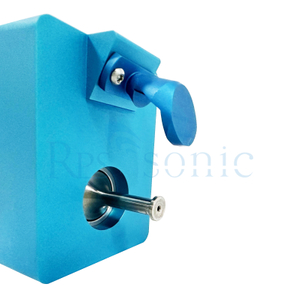

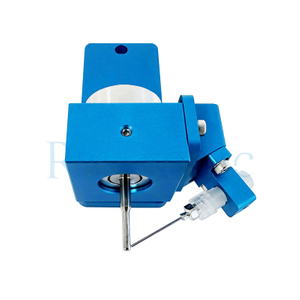

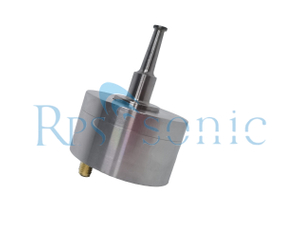

◆Automated wave equipment, using nozzle technology, can provide uniform and efficient thin film spraying;

◆High coating thickness control accuracy: can prepare coatings from twenty nanometers to tens of microns, and accurately control coating thickness; ◆Spraying uniformity: >95%;

◆Solution conversion rate: ≥95%, 4 times that of traditional two-fluid spraying;

◆Equipped with multiple nozzles working in parallel; (expandable)

◆Maximum spraying area: 400*400mm; (expandable)

◆High-precision constant flow liquid supply technology, can achieve uninterrupted and constant liquid supply;

◆Laser alignment: assist users to locate the nozzle position conveniently and quickly;

◆Imported high-precision precision pressure reducing valves and liquid valves to achieve high-speed and stable gas-liquid coordination;

◆Nozzle, liquid pipeline self-cleaning system, built-in waste liquid recovery system, waste gas exhaust system;

◆Online dispersed liquid supply system, hundreds of process formula storage;

◆Micron-level microporous vacuum absorption heating, suitable for flexible substrates such as battery separators.

The application of ultrasonic spraying technology in the medical industry not only improves the manufacturing level of medical devices, but also brings safer and more effective medical solutions to patients. Medical manufacturing enterprises need to actively embrace technological innovation, strengthen technology research and development and personnel training, take ultrasonic spraying technology as a breakthrough, promote the development of medical manufacturing to the direction of precision and intelligence, and make greater contributions to the cause of human health. With the continuous progress of technology, ultrasonic spraying technology will play a more important role in the field of medical manufacturing, and promote the medical industry to a higher level.

RPS-SONIC Ultrasonic spraying equipment videos:

English

English