Medical blood collection tubes (also known as vacuum blood collection tubes) are special containers used to collect, transport and store blood samples in clinical tests. They are usually used in conjunction with disposable blood collection needles and needle holders to automatically draw blood through the principle of negative pressure.

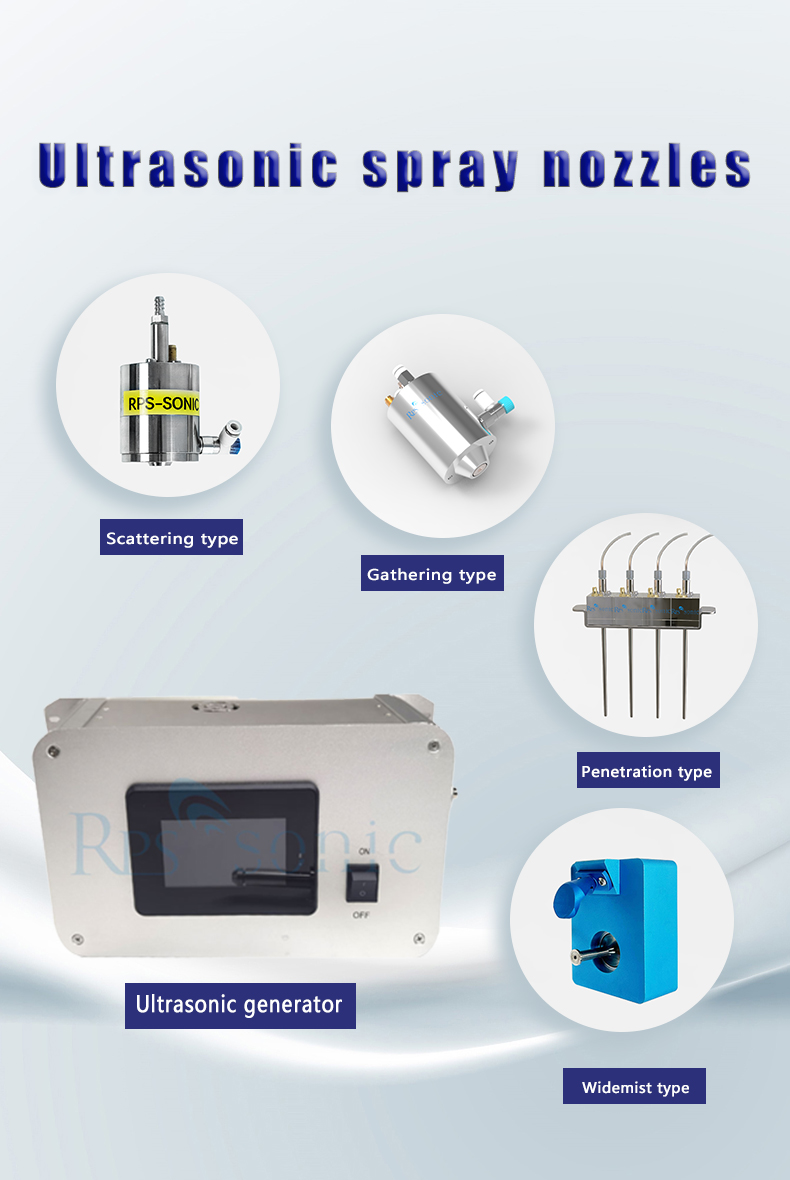

Ultrasonic technology is mainly used for inner wall coatings (such as anticoagulants, separation gels, coagulants, etc.) in the spraying process of medical blood collection tubes. Its core advantages lie in high precision, uniformity and contactless spraying.

1. Principle of ultrasonic spraying

Technical basis: High-frequency ultrasonic waves (usually 20kHz~200kHz) are used to atomize liquid additives into micron-sized particles and spray them onto the inner wall of the blood collection tube through carrier gas.

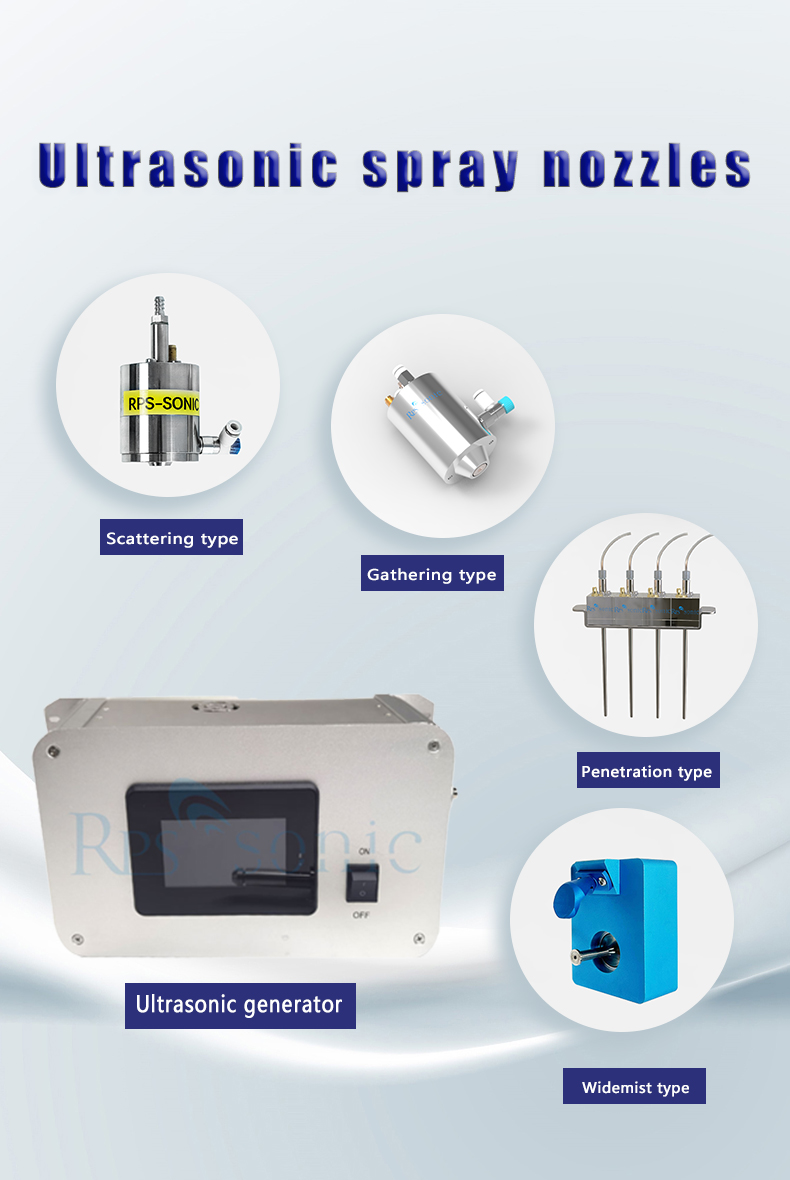

Core components:

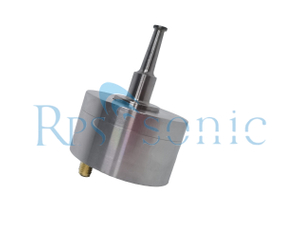

Ultrasonic generator: Generates high-frequency electrical signals.

Transducer: Converts electrical energy into mechanical vibrations.

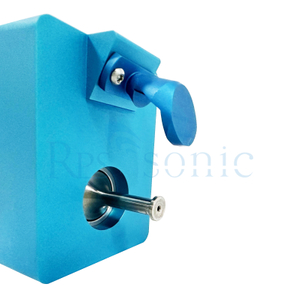

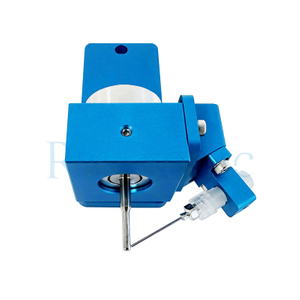

Atomizing nozzle: Vibrates liquid to form uniform droplets (particle size can be controlled at 5~50μm).

RPS-SONIC atomizer nozzles can be used to apply uniform thickness of material to the side wall of blood collection tubes while minimizing material deposition at the bottom of the tube.

RPS-SONIC ultrasonic nozzles minimize product clumping or material agglomeration. Our technology does not compromise coating solutions or drug chemistry by overexposure to the atmosphere during application, nor does it cause shearing or separation of materials in suspension. RPS-SONIC spray nozzles eliminate clogging, provide uniform film thickness, dense films, low spray velocities, and minimal overspray.

Ultrasonic atomizer nozzles produce fine droplets for uniform, controlled coatings on medical devices and sensitive, small devices. The nozzle spray velocity is low, making it suitable for thin layers of valuable chemicals with little overspray. Ultrasonic nozzles provide several key advantages not only in blood collection tube coating, but also in dozens of precision medical device coating and manufacturing applications. RPS-SONIC nozzles provide excellent repeatability in spray velocity and droplet size, and significantly reduce the spray material used.

Ultrasonic atomizer nozzle with extended angle surfactant, anticoagulant, clot activator and non-vacuum blood collection tube (VBCT and BCT), with anticoagulant (EDTA K2, EDTA K3, lithium heparin, sodium heparin) and coagulation promoter (silicon dioxide, thrombin, snake venom).

Advantages

2. Specific application in blood collection tube production

(1) Anticoagulant/additive spraying

Applicable types: EDTA (purple cap), heparin (green cap), sodium citrate (blue/black cap), etc.

Technical advantages:

Uniformity: avoid local concentration unevenness caused by traditional immersion method.

Cost saving: reduce the amount of additives (coating thickness can be accurate to 0.1μm).

Pollution-free: non-contact spraying reduces the risk of cross-contamination.

(2) Separation gel spraying

Application: golden cap blood collection tube (serum separation tube).

Challenge: separation gel needs to form a stable inert barrier.

Ultrasonic solution:

The silicone oil or polymer colloid is atomized and then sprayed to the middle of the tube wall.

It is heated and liquefied during centrifugation to form a uniform barrier.

(3) Coagulant spraying

Application: red cap/gold cap blood collection tube.

Improvements: Traditional spray drying may clog the nozzle, but ultrasonic atomization can avoid this problem.

3. Key process parameters

Parameters Impact Typical values

Ultrasonic frequency Atomized particle size (frequency ↑→particle ↓) 50kHz~120kHz

Liquid viscosity High viscosity requires frequency reduction or heating 1~100cP (such as EDTA solution)

Carrier gas pressure Control spray coverage 0.1~0.3MPa

Tube rotation speed Ensure circumferential uniformity of coating 100~300rpm

4. Comparison with traditional spraying technology

Technology Ultrasonic spraying Traditional spraying (air pressure/centrifugal)

Uniformity Coefficient of variation of coating <3% 5%~15%

Material utilization >95% 60%~80%

Applicable liquids High/low viscosity are both possible Low viscosity is preferred

Maintenance cost Nozzle is not clogged Need to clean the clog regularly

Ultrasonic technology has advantages over traditional air systems because its low-speed, airless spraying can be easily controlled to the target area within the equipment and achieve layering of the coating. Other advantages of ultrasonic spray technology for vacuum blood collection tubes and blood collection tubes include: high transfer efficiency, resulting in consistent amount of deposited reagents, reducing manufacturing costs. Production process validation (GMP, ISO 13485, etc.) is easier with consistent reagent deposition. Perfect solvent-free process, which is harmless, low-cost and environmentally friendly.

English

English