Does ultrasonic power affect the extraction of cannabidiol?

Industrial hemp (Cannabis sativa L.) is widely planted because it is widely used in textiles, oil, nutraceuticals, cosmetics and biofuels. Recently, the medicinal value of cannabinoids in industrial hemp has become a research hotspot. At present, more than 80 cannabinoids have been identified, mainly cannabidiol, tetrahydrocannabinol, cannabinol, cannabicyclol, cannabichromene and cannabitriol. Studies have shown that cannabinoids have therapeutic effects on human physiology and psychology, so they have potential medicinal value. However, tetrahydrocannabinol can be used as a narcotic, so many countries stipulate that the content of tetrahydrocannabinol in industrial hemp must be less than 0.3%. Among them, cannabidiol (CBD) is the most important cannabinoid. It is a pale yellow crystal that is almost insoluble in water. It is easily decomposed by light and heat, and has no hallucinogenic effect. In recent years, with the in-depth research on CBD at home and abroad, it has been found that CBD has high medicinal value. Wang et al. found that CBD can protect alcoholic liver damage. Wirth et al. found that CBD has anti-inflammatory and antioxidant effects. In the cosmetics field, Huber et al. found that CBD is a natural cosmetic raw material that can soothe and moisturize the skin and has analgesic effects. Li Yanmei et al. found that CBD is effective for skin inflammation, redness, skin sensitivity and other symptoms, and also has a certain effect on treating acne. In terms of medicinal use, Liu Kai et al. [11] and Boehnke et al. found that CBD can relieve muscle pain. Moltke et al. found that CBD has the effect of improving anxiety and insomnia. However, CBD is unstable and is a photosensitive and heat-sensitive substance that is easily decomposed during the extraction process. Therefore, how to improve the yield of CBD and ensure the stability of CBD during the extraction process has become a research hotspot.

In previous studies, CBD was generally extracted by hot reflux of organic solvents such as methanol, ethanol, chloroform and acetone. This method is low-cost and simple to operate, but it is highly polluting and has safety hazards such as flammability and explosion.

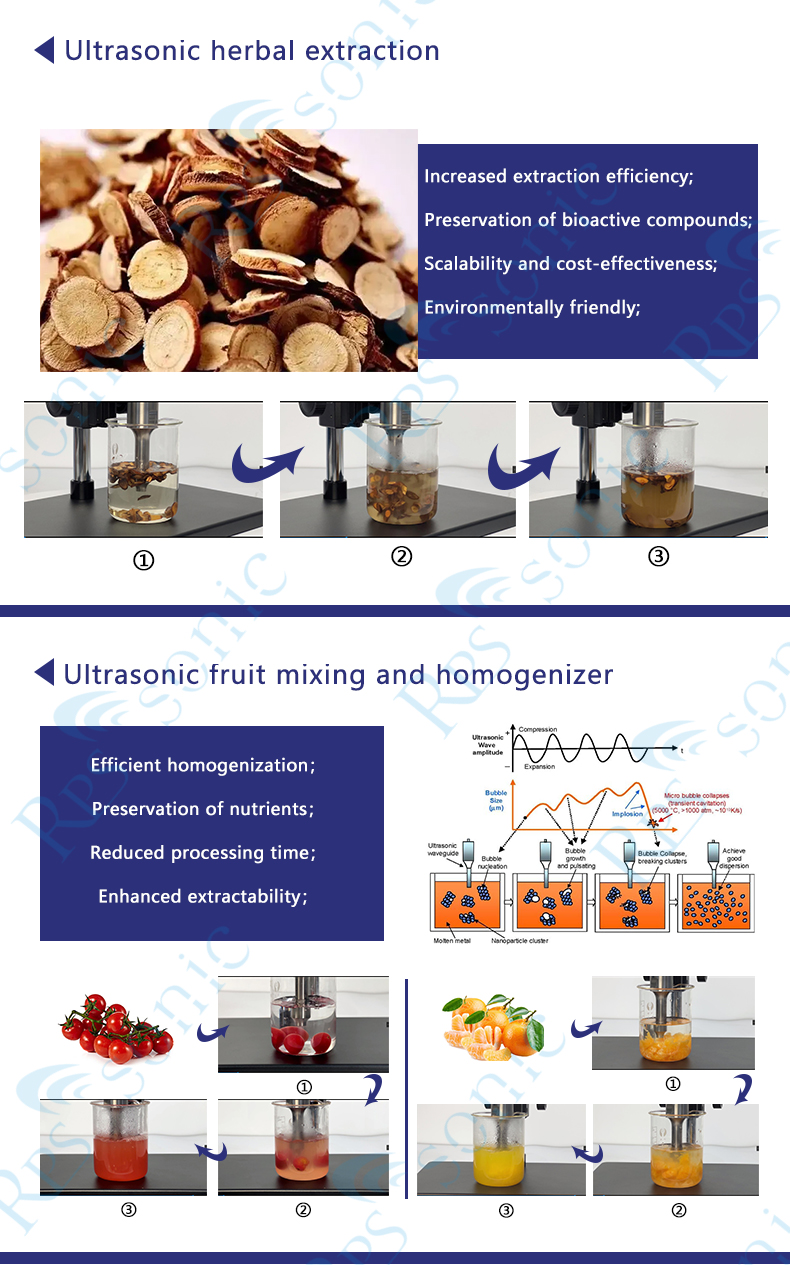

In order to solve these problems, some new extraction methods have been adopted. Microwave-assisted extraction and ultrasound-assisted extraction have the advantages of fast extraction speed, high extraction rate and simple operation, but they still require organic solvents for extraction. CO2 supercritical fluid extraction is a method of using CO2 supercritical fluid to replace organic solvents for extraction. It has the advantages of being green, environmentally friendly, pollution-free and having a high extraction rate, but it has problems such as high energy consumption, complex operation and high equipment cost.

Recently, a new type of extraction solvent, ionic liquid, has become a research hotspot. Ionic liquids are salts that are composed of symmetrical and large organic cations and relatively small inorganic anions, and are liquid at room temperature or near room temperature. Ionic liquids have the characteristics of almost negligible vapor pressure, non-volatility, non-flammability, good chemical stability, non-toxicity, pollution-free and designability. Ionic liquids appeared in the 1970s as electrolytes for batteries. Because ionic liquids have the designability of regulating their physical and chemical properties by changing the composition of anions and cations, ionic liquids have developed rapidly and are widely used in chemical, pharmaceutical and food fields. Ionic liquids can be used as catalysts and extractants for the extraction of active substances, which can accelerate the extraction efficiency of organic solvents or replace organic solvents for extraction. Xu et al. explained that imidazole ionic liquids can be used as catalysts and extractants for the oxidative desulfurization reaction of dibenzothiophene. Mazid et al. found that ionic liquids can enhance the activity and stability of bioactive substances. Stolte et al. found that when the cation of the ionic liquid is an imidazole group, it is very easy to hydrolyze under the action of microorganisms, while the pyridine group is difficult to be decomposed, which clarifies that imidazole ionic liquids are safe for the environment and human body, and pyridine ionic liquids are toxic.

In view of this, this study uses industrial hemp leaves as raw materials, uses imidazole ionic liquids as catalysts for a certain concentration of ethanol aqueous solution, and reduces the amount of organic solvent used on the basis of improving the extraction capacity of ethanol aqueous solution, and ensures the stability of CBD during the extraction process. The ultrasonic method is then assisted to further improve the yield of CBD. And through single factor experiments, Plackett-Burman experimental design and response surface Box-Behnken experimental design, the extraction process of CBD in industrial hemp leaves is optimized, and an efficient and safe extraction method is established to provide experimental basis for the extraction process of CBD.

In order to improve the economic value of industrial hemp, this study uses industrial hemp leaves as raw materials, uses ionic liquid-assisted ultrasonic method to extract cannabidiol (CBD), an active ingredient with medicinal value, and optimizes the extraction process.

In this study, the yield of CBD was used as an indicator. NTF2 was first selected from 16 imidazole ionic liquids as the best extraction solvent. Then, a single factor experiment was conducted on the six factors affecting the yield of CBD by ionic liquid-assisted ultrasonic extraction (ultrasonic power, ultrasonic temperature, ultrasonic time, ethanol solution concentration, ionic liquid molar concentration and liquid-to-solid ratio). The ethanol concentration was determined to be 65% and the ionic liquid molar concentration was 0.3 mol/L (prepared with 65% ethanol solution).

Based on this result, four significant factors (ultrasonic power, ultrasonic temperature, ultrasonic time and liquid-to-solid ratio) were screened out using the Plackett-Burman experimental design. The extraction process was further optimized using the response surface Box-Behnken experimental design.

The optimal extraction process conditions for the significant factors of CBD were determined to be: ultrasonic power 280 W, ultrasonic temperature 50 ℃, ultrasonic time 62.5 min, and liquid-to-solid ratio 25 mL/g. Under the above conditions, the CBD extraction rate of ionic liquid [C8mim]NTF2 was 7.66%±0.2%, the CBD extraction rate of methanol was 6.42%±0.3%, and the CBD extraction rate of 65% ethanol solution was 5.81%±0.2%.

That is, the extraction capacity of CBD is ionic liquid [C8mim]NTF2>methanol>65% ethanol solution. The CBD degradation experiment showed that the CBD degradation rate of ionic liquid [C8mim]NTF2 was 16.40%±0.3%, which was less than 24.65%±0.6% of methanol and 32.88%±0.5% of 65% ethanol solution. The results showed that after adding ionic liquid [C8mim]NTF2 to 65% ethanol solution, the degradation rate of CBD could be reduced and the yield of CBD could be increased. This study proves that ionic liquid is both a protective agent for CBD and an excellent extraction solvent for CBD. The ionic liquid-assisted ultrasonic extraction process for CBD was developed to provide data support for the development and utilization of industrial hemp.

English

English