Application of Ultrasonic Spraying Technology in Medical Industry

Ultrasonic spraying technology is reshaping the face of medical manufacturing. This innovative technology uses high-frequency ultrasonic energy to transform liquids into uniform micron-sized droplets, providing unprecedented precision coating solutions for medical device manufacturing. As the medical industry's requirements for precision and reliability continue to increase, ultrasonic spraying technology has shown unique advantages and has become an important force in promoting the advancement of medical technology.

Technical principle and system composition

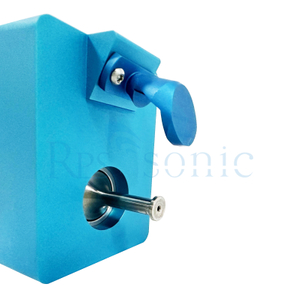

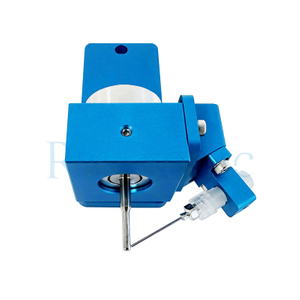

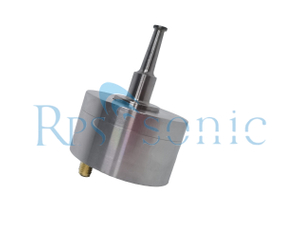

The core of the ultrasonic spraying system is the ultrasonic generator, transducer and atomizing nozzle. When working, the ultrasonic generator generates a high-frequency electrical signal, which is converted into mechanical vibration through the transducer, so that the tip of the nozzle generates high-frequency vibration. When the liquid flows through the vibrating surface, it is broken into uniform micron-sized droplets to form a precisely controllable spray.

Compared with traditional spraying technology, ultrasonic spraying has significant advantages. It can produce droplets with uniform particle size distribution, and the minimum droplet diameter can reach less than 10 microns. The spray angle and flow rate can be precisely controlled, and the coating uniformity is significantly improved. At the same time, this technology has high atomization efficiency, and the material utilization rate can reach more than 95%, which is much higher than the 30-40% of traditional spraying.

In the field of medical manufacturing, ultrasonic spraying technology shows unique applicability. It can handle liquids of various viscosities, including drug solutions, biomaterials and nanosuspensions. The gentle atomization process does not destroy the activity of the drug, and is particularly suitable for the spraying of biological agents.

Application in medical devices

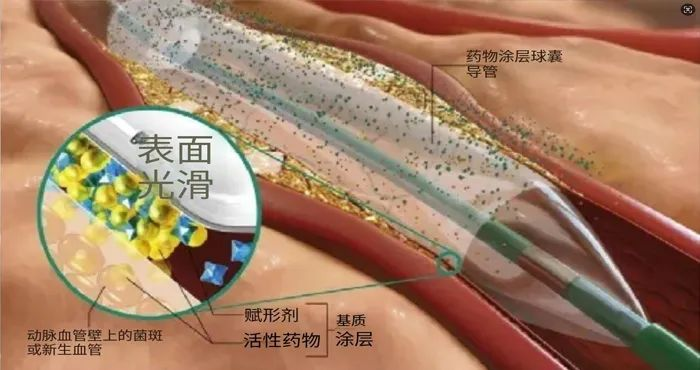

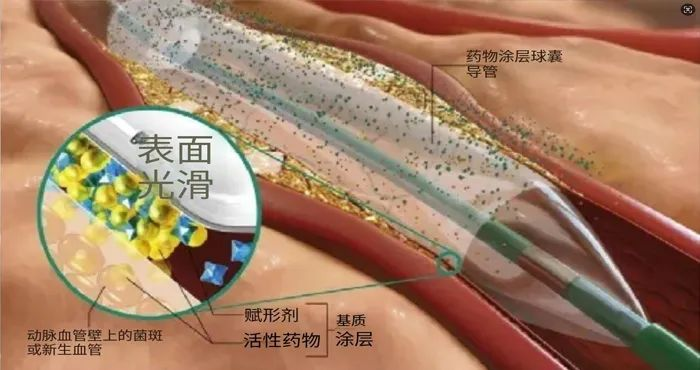

In the manufacture of drug-eluting stents, ultrasonic spraying technology plays a key role. It can evenly coat the anti-proliferative drugs on the surface of the stent, forming precise drug dosage control. Compared with traditional spraying, the uniformity of the drug coating is improved by more than 50%, significantly reducing the incidence of postoperative restenosis.

In the manufacture of tissue engineering scaffolds, ultrasonic spraying technology provides an innovative solution for biomaterial coating. It can evenly coat the surface of the stent with extracellular matrix proteins, growth factors and other bioactive substances to promote cell adhesion and proliferation. This precise coating technology significantly improves the biocompatibility and functionality of tissue engineering scaffolds.

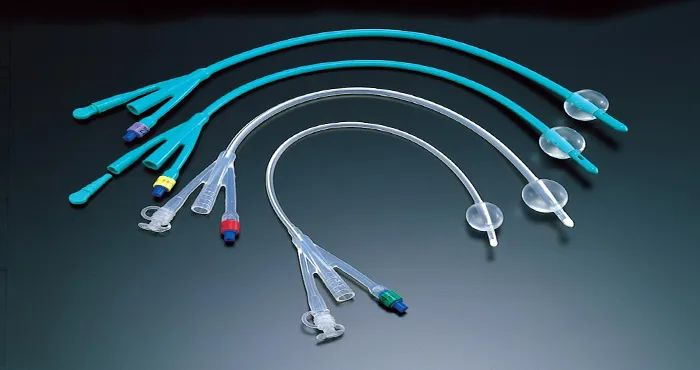

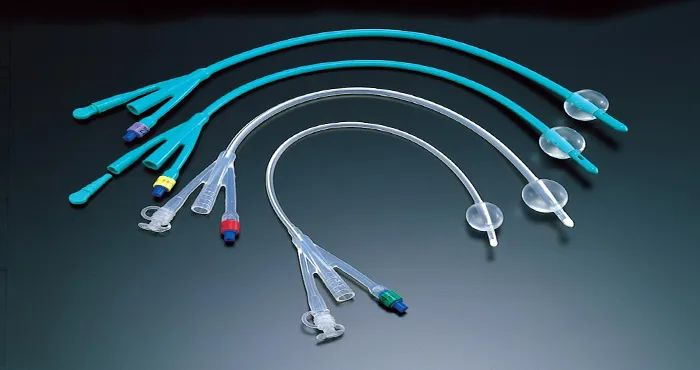

Ultrasonic spraying technology has shown great potential in the application of antimicrobial coatings. It can evenly coat antimicrobial agents such as silver ions and antibiotics on the surface of medical devices to form a durable antimicrobial protective layer. In products such as catheters and orthopedic implants, this technology has significantly reduced the incidence of hospital infections.

Quality Control and Future Outlook

In medical manufacturing, coating quality control is crucial. Ultrasonic spraying technology ensures high consistency of coating thickness and uniformity through precise parameter control. The application of online monitoring system realizes real-time monitoring and quality traceability of coating process. Statistics show that the qualified rate of medical device products using ultrasonic spraying technology can reach more than 99.5%.

Technological innovation is the key driving force for the development of the medical industry. New ultrasonic spraying equipment integrates artificial intelligence and Internet of Things technology to realize intelligent control and remote monitoring. The application of adaptive control system enables the equipment to automatically adjust parameters to ensure the best spraying effect.

Future development trends show that ultrasonic spraying technology will play a greater role in the manufacture of personalized medical devices. By precisely controlling the composition and structure of the coating, the surface of medical devices with specific functions can be customized. In the fields of intelligent drug release systems, biosensors, etc., this technology will also show great potential.

The application of ultrasonic spraying technology in the medical industry not only improves the manufacturing level of medical devices, but also brings safer and more effective medical solutions to patients. Medical manufacturing companies need to actively embrace technological innovation, strengthen technology research and development and talent training, use ultrasonic spraying technology as a breakthrough, promote medical manufacturing to develop in the direction of precision and intelligence, and make greater contributions to human health. With the continuous advancement of technology, ultrasonic spraying technology will surely play a more important role in the field of medical manufacturing and promote the medical industry to a higher level.

The application of ultrasonic spraying technology in the medical industry mainly includes the following aspects:

(1) Medical drug coating: Ultrasonic spraying technology can combine drugs with polymer materials, break drug solutions or suspensions into micron- or even nano-scale droplets through high-frequency vibration, and then spray the solution onto the surface of the substrate through the carrier gas to form a uniform drug coating. This technology has the advantages of good coating uniformity, high drug utilization rate, and strong process controllability. It is suitable for a variety of medical applications such as drug eluting stents, antibacterial coatings, and tissue engineering scaffolds.

(2) Medical non-woven fabrics: In the field of medical non-woven fabrics, ultrasonic spraying technology can evenly spray antibacterial agents and antiviral agents on the surface of non-woven fabrics to improve their antibacterial properties; at the same time, waterproof and breathable materials can also be sprayed on non-woven fabrics to enhance their user experience. In addition, this technology can also develop environmentally friendly packaging solutions, which is in line with the development trend of green production.

(3) Biosensor preparation: In the preparation of biosensors, ultrasonic spraying technology can accurately control the size and distribution of droplets to achieve uniform coating coverage. This technology performs well in protein detection, enzyme sensors, DNA sensors and environmental pollutant monitoring. It can improve the sensitivity and detection stability of sensors, extend their service life, and is suitable for rapid response biological detection applications.

(4) Medical device coating: Ultrasonic spraying technology can form coatings with anti-corrosion, antibacterial, anticoagulant and other functions on the surface of medical devices such as catheters and implants. This coating can not only improve the service life and safety of medical devices, but also reduce the risk of complications during use.

(5) Drug delivery: Using ultrasonic spraying technology, drug solutions or suspensions can be evenly applied to the target area to achieve local or systemic drug administration. This precise drug delivery method helps to improve the efficacy of drugs and reduce side effects.