Ultrasonic Frequency. Ultrasonic welding transducers are designed to operate at a specific frequency from 15 to 300 kHz for different systems and applications. Most metal welding systems operate at 20 to 40 kHz, with 20 kHz being the most common frequency.

Vibration Amplitude. The vibration amplitude of the welding tip is tied directly to the energy delivered to the weld. Ultrasonic vibration amplitudes are quite small—10, 30, or 50 microns at the weld, and seldom exceed 100 microns (approximately 0.004 inch). In some welding systems, the amplitude is a dependent variable; that is, it is related to the power applied to the system. In other systems the amplitude is an independent variable capable of being set and controlled at the power supply through a feedback control system.

Static Force. The force exerted on the workpieces via the welding tip and anvil creates intimate contact between the opposing surfaces as the weld vibrations begin. The magnitude of the force, which depends on the materials and thicknesses, as well as the size of the weld produced, may be from tens to thousands of newtons. For example, producing a weld of 40 mm2 in a 6000 series aluminum may use force of 1,500 N, while 10 mm2 welds in 0.5-mm-thick soft copper sheet may require only 400 N.

Power, Energy, and Time. While listed as separate weld parameters, power, energy, and time are best examined together since they are all closely related. When a weld is made, the voltage and current from the power supply result in electric power that flows to the transducer during the weld cycle. The energy delivered is the area under the weld power curve. Most welding power sources are rated by the peak power they can deliver, with this varying from a few hundred watts to several kilowatts. Most weld times are found to be less than one second. Based on constant power output, a 0.4-second weld from a 2-kW welder would deliver 800 joules of energy.

Materials. This encompasses a wide range of issues and parameters relating to ultrasonic metal welding. First is the type of material or material combination. Most materials and material combinations have been found to be weldable in some fashion, although specific weld parameter and performance data is generally lacking for most of them. The properties of the material, including modulus, yield strength, and hardness, are a key consideration.

Generally speaking, soft alloys like aluminum, copper, nickel, magnesium, gold, silver, and platinum are most easily welded ultrasonically. Harder alloys such as titanium, irons and steels, and nickel-based aerospace alloys and refractory metals (molybdenum and tungsten) are more difficult.

Material surface characteristics is another parameter, with these including finish, oxides, coatings, and contaminants.

Part Geometry. The shapes of the welded parts play an important role, the dominant factor being part thickness. Generally speaking, thin parts have a better chance of achieving a successful ultrasonic weld. Increasing the part thickness, in particular the part contacting the welding tip, requires a larger welding tip area, more static force, and higher weld power. Maximum achievable thicknesses will depend on the material and the welding power source's available power.

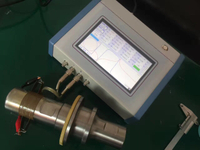

Tooling. Composed of the sonotrode/welding tip and the anvil, tooling serves to support the parts and to transmit ultrasonic energy and static force. In most cases, the tool tip is machined as an integral part of a solid sonotrode , but in some cases detachable tool tips are used. The tooling contact surfaces typically have machined knurled patterns of grooves and lands or other surface roughening to improve workpiece gripping.

While the weld tip and anvil contact surfaces are usually flat, the weld tip may be designed with a slight convex curvature in order to change the contact stresses.