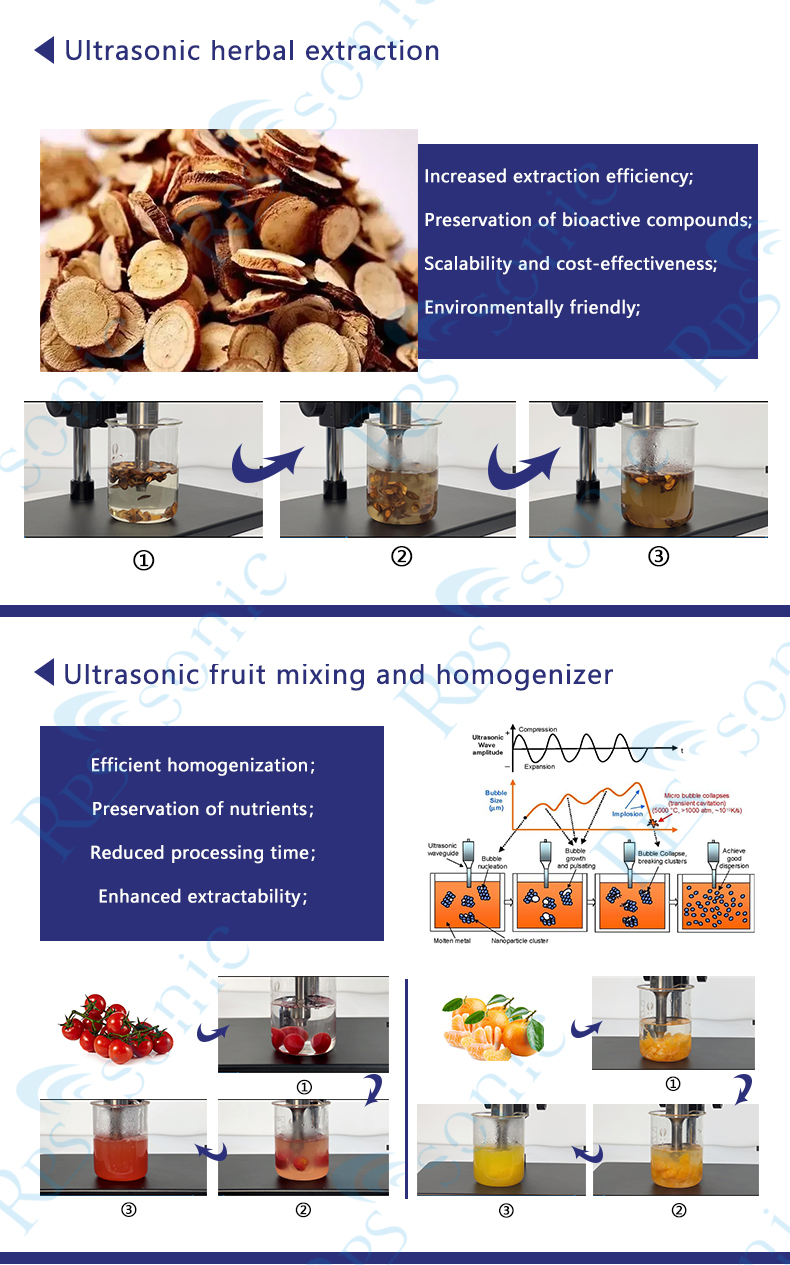

Ultrasound-assisted extraction is widely used to release valuable intracellular substances from plant materials. Target extracts include lipids/fatty acids, proteins, vitamins, polyphenols, and other bioactive compounds. As a process intensification technique, ultrasound extraction of edible oils, such as extra virgin olive oil, avocado oil, sunflower seed oil, flaxseed oil, etc., can increase oil (fatty acid) yield, shorten extraction time, and reduce or eliminate solvent consumption.

Ultrasound extraction is purely a mechanical extraction method that can extract bioactive compounds from plants and medicinal plants, producing high-quality plant extracts. This technology is considered organic as it eliminates the risk of using non-natural solvents, making it recommended for those aiming to produce "organic-certified" products.

Ultrasound extraction is the preferred technique for separating bioactive compounds from herbal plants. Ultrasound-assisted extraction techniques may help increase the value of certain food by-products as sources of natural compounds. They have a dual effect on vegetable matrices, significantly reducing extraction time and reducing or disrupting bacteria.

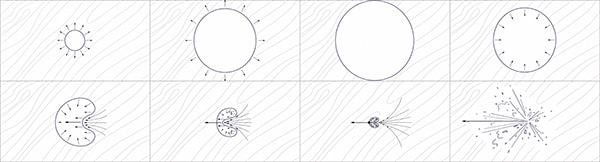

Principle:

Ultrasound extraction is achieved by coupling high-power, low-frequency ultrasound into a slurry composed of plant materials in a solvent. High-power ultrasound is coupled into the slurry through a probe-type ultrasonic processor. High-energy ultrasound propagates through the liquid, creating alternating cycles of high pressure or low pressure, leading to the phenomenon of cavitation.

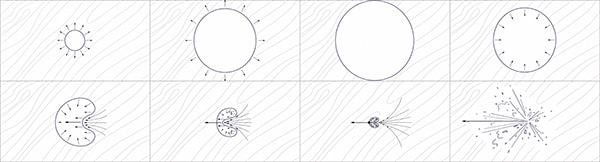

Cavitation Effect:

Ultrasound extraction is based on repeated cycles of high pressure and low pressure. The alternating high-pressure and low-pressure cycles at 20,000 times per second during ultrasonic processing generate intense shear forces and liquid jets. This extreme stress can overcome the selectivity of cell membranes, rapidly disrupting cell walls, leading to high-quality transfer between the internal cell and the surrounding solvent. With ultrasound extraction, higher yields and shorter extraction times can be achieved.

Name1

Name2

Extraction of Olive Oil

Ultrasonic machines can be integrated into conventional olive oil production lines. The performance of the extraction process and the extraction capacity of olive oil factories can be improved by ultrasonically treating olive paste. Ultrasonic processing is a fundamental step in the mechanical extraction process of olive oil, which can significantly enhance this scenario. The efficiency of paste formation depends on the rheological properties of the olive paste and process parameters of paste formation, such as time and temperature. These factors greatly affect the yield and quality of extra virgin olive oil.

When intense ultrasonic waves are applied to olive paste, cavitation occurs. Cavitation refers to the formation, growth, and collapse of bubbles in alternating pressure cycles. Ultrasonic cavitation disrupts cell structures, releasing soluble compounds from olive plant tissues and improving mass transfer. Therefore, extraction rates and yields are significantly increased through ultrasonic processing. Oil in ultrasonically treated olive paste also exhibits lower bitterness and higher levels of tocopherols, chlorophyll, and carotenoids.

Ultrasonic processing is a gentle non-thermal food processing technique that releases oil and bioactive compounds (such as antioxidants, phenols, vitamins) from olive paste. The olive paste can be uniformly processed through a continuous online process in the ultrasonic cavitation zone. Ultrasonic processing is also beneficial for process temperature: it can instantly heat and greatly reduce the preheating time of olive paste, allowing the process temperature to be easily maintained at the optimal level (e.g., 28-30°C).

Extraction of Avocado Oil

Using an ultrasonic extraction machine to process avocado pulp can increase the extraction rate of avocado oil by 15-24%. Ultrasonic processing aids in cold-pressing avocado oil by increasing oil yield. Non-thermal pressing techniques help avocado oil retain its valuable nutrients, aromatic flavors, and vibrant green color. Ultrasonic quick solubilization and extraction of avocado flesh improve oil release and potentially reduce solubilization time in industrial avocado oil production without compromising quality.

Avocado oil extracted through ultrasonic pressing is carefully maintained, preserving all its healthy nutrients such as vitamins, enzymes, micronutrients, and flavor components. Research indicates that ultrasonic processing can increase oil extraction rates, reduce extraction times, and maintain a high nutritional profile of vegetable oils.

Ultrasonic extraction equipment offers many advantages, making it an excellent extraction method. Due to its high yield, high-quality extracts, fast process, low investment and operating costs, safe and user-friendly operation, ultrasonic extraction is the preferred method for extraction processes in both small-scale and industrial production.

Applying high-power ultrasound to liquids and slurries induces intense cavitation and shear forces. In vegetable cell slurries from leaves, buds, flowers, stems, and other plant parts, ultrasound shear forces disrupt vegetable cells and release bioactive compounds. Ultrasonic extraction has been recognized as an efficient and reliable technology for separating bioactive plant compounds. Particularly in the production of high-quality herbal extracts, ultrasonic processing is convincing due to its high yield, excellent quality, and rapid processing times. The application of ultrasound is a mechanical, non-toxic, safe, and environmentally friendly process.

In conclusion, ultrasonic extraction can be used as a standalone method for extracting edible oils from seeds and oil-rich fruits or integrated/adapted into existing conventional edible oil production equipment to improve oil yield and quality. Ultrasonic extraction equipment is easy to install, requiring minimal space (occupying a small footprint), thus allowing retrofitting into existing oil mills. Industrial ultrasonic extraction machines are robust, durable, and industrial-grade, capable of operating round-the-clock in heavy-duty and demanding environments.