Ultrasonic Sonotrode for Welding System with FEA Analysis

First. The amplitude parameter of the horn.

The amplitude is a key parameter for the material to be welded, which is equivalent to the temperature of ferrochrome. If the temperature is not reached, it will not be welded. If the temperature is too high, the raw material will burn or cause structural damage and strength will deteriorate. .

Because the transducers selected by each company are different, the amplitude of the transducer output is different. After adapting the different ratios of the horn and the horn, the working amplitude of the horn can be corrected to meet the requirements. The output amplitude of the energy device is 10-20μm, and the working amplitude is generally about 30μm. The variation ratio of the horn and the welding horn is related to the shape of the horn and the welding horn, the front and back area ratio and other factors. In terms of shape, such as exponential luffing, functional luffing, stepwise luffing, etc., the influence on the transformation ratio is large, and the front-to-back area ratio is proportional to the total transformation ratio. If your company chooses welding machines of different company brands, the easiest way is to make the amplitude parameters stable according to the proportion of the working welding horn.

Second. horn frequency parameters

Any company's ultrasonic welding machine has a center frequency, such as 15KHz, 20KHz, etc. The operating frequency of the welding machine is mainly determined by the mechanical resonance frequency of the transducer (Transducer), the horn (Booster) and the welding horn (horn). .

The frequency of the generator is adjusted according to the mechanical resonance frequency to achieve uniformity, so that the horn operates in a resonant state, and each part is designed as a one-half wavelength resonator. Both the generator and the mechanical resonance frequency have a resonant working range. For example, the general setting is 0.5KHz. In this range, the welding machine can basically work normally. When we make each welding horn, we will adjust the resonant frequency. It is required that the resonant frequency and design frequency error is less than 0.1KHZ. For example, for a 20KHz welding horn, the frequency of our welding horn will be controlled at 19.90-20.10KHz with an error of 5%. o.

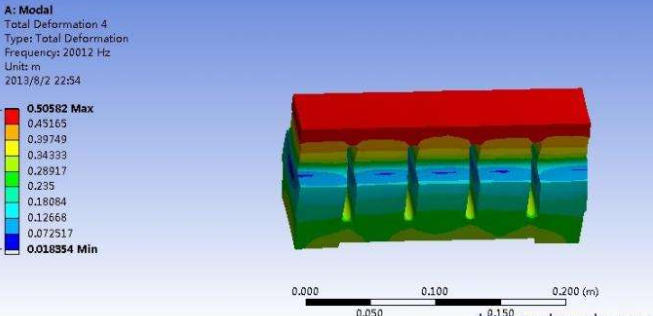

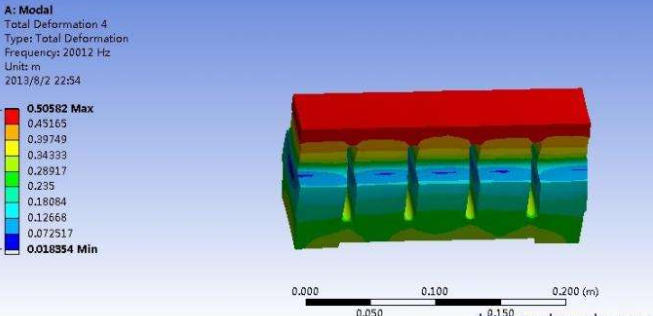

Third. Vibration node

The horn and the horn are designed to be a half-wavelength resonator with an operating frequency. In the working state, the amplitude of the two end faces is the largest and the stress is the smallest, while the amplitude of the node corresponding to the middle position is zero and the stress is the largest. The position of the node is generally designed to be a fixed position, but the usual fixed position is designed to have a thickness greater than 3 mm, or the groove is fixed. Therefore, the fixed position does not necessarily have a zero amplitude, which causes a certain sound and a part of the sound. Energy loss, for sound, is usually isolated from other components by rubber rings, or shielded with sound insulation; energy loss is considered when designing amplitude parameters.Ultrasonic Sonotrode for Welding System with FEA Analysis will hepl check the vibration node too.

Forth. Processing precision

Ultrasonic welding horn, because it works under high frequency vibration, should try to maintain a symmetrical design to avoid the unbalanced stress and lateral vibration caused by the asymmetry of sound wave transmission. The longitudinal transmission of ultrasonic vibrations, for the entire resonant system), unbalanced vibrations can cause heat and breakage of the weld hair.

Ultrasonic welding is used in different industries, and the processing accuracy requirements are different. For particularly thin workpieces, such as lithium-ion battery pole pieces and tab welding, gold foil coating, etc., the processing accuracy is high, all our processing equipment uses CNC equipment (such as machining centers, etc.) In order to ensure that the precision of the processing meets the requirements.

Fifth. horn life

- The service life of the welding horn only depends on two aspects: first, material, second, process.

Material aspects:

Ultrasonic welding requires metal materials to be flexible (small mechanical loss during sonic transmission), so the most commonly used materials are aluminum alloys and titanium alloys.

The material is the main reason for ensuring the life of the ultrasonic horn and the effect of the welded product. The process of completing the horn is complicated, so it is not only the horn engineer design that must carefully select the material.

It is also necessary to know what kind of material is required for the product itself to avoid inadvertent influence on its timeliness and quality.