Ultrasonic Sonochemistry Equipment for Hemical Reactions And Processes

What's the theory of ultrasonic sonochemistry?

Sonochemistry is the application of ultrasound to chemical reactions and processes. Ultrasound is the part of the sonic spectrum which ranges from about 20 kHz – 10 MHz and can be roughly subdivided in three main regions: low frequency, high power ultrasound (20 – 100 kHz), high frequency, medium power ultrasound (100 kHz – 1 MHz), and high frequency, low power ultrasound (1 – 10 MHz). The range from 20 kHz to around 1 MHz is used in sonochemistry whereas frequencies far above 1 MHz are used as medical and diagnostic ultrasound.

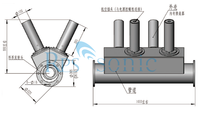

Industrial grade ultrasonic nanomaterial dispersers are mainly used for large-scale industrial production. Industrial high-power ultrasonic sonochemical processing equipment, with high power, high efficiency, large radiation area, suitable for large-scale industrial production, with real-time monitoring of frequency power, adjustable power, overload alarm function, length of 930mm. Industrial grade Jinghao brand ultrasonic nano material disperser has 80%-90% energy conversion efficiency

Physical Effects

There are three different theories about cavitation – the hot-spot, the electrical and the plasma theory. The most popular one is the hot spot theory. Thus, it has been experimentally shown that the cavitational collapse creates drastic conditions inside the medium for an extremely short time: temperatures of 2000-5000 K and pressures up to 1800 atm inside the collapsing cavity. A remarkable event during the cavitation collapse is the emission light under certain conditions (Sonoluminescence). Furthermore, the collapse causes a couple of strong physical effects outside the bubble: shear forces, jets and shock waves. Thus, there are basically two groups of effects: radical and mechanical effects. These cavitation-induced effects can cause physical, chemical, and biological effects. Thus, ultrasound has been found applications in chemistry, materials and life sciences as well as medicine.

Chemical Effects

There is no doubt that the origin of sonochemical effects is cavitation. There are three possible reaction sides of a collapsing bubble: the cavity interior, the bubble vicinity and the bulk solution. Due to the extreme conditions inside the medium and other cavitation effects the following effects depending on the sonication conditions have been found:

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

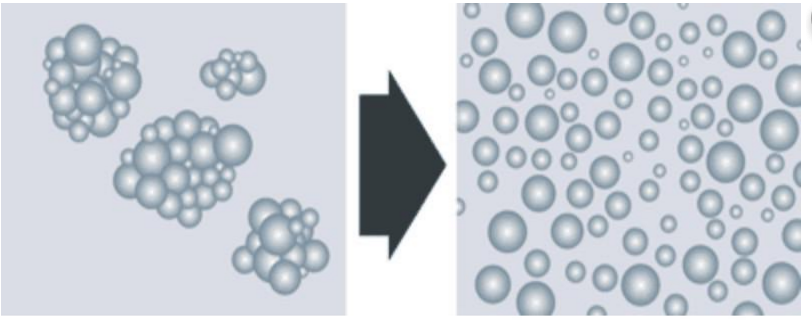

Before ultrasonic treatment After ultrasonic treatment

Application:

• Cell disrupter (extraction of plant substances, disinfecting, enzyme deactivation)

• Therapeutic ultrasound, i.e. induction of thermolysis in tissues (cancer treatment)

• Decrease of reaction time and/or increase of yield

• Use of less forcing conditions e.g. lower reaction temperature

• Possible switching of reaction pathway

• Use of less or avoidance of phase transfer catalysts

• Degassing forces reactions with gaseous products

• Use of crude or technical reagents

• Activation of metals and solids

• Reduction of any induction period

• Enhancement of the reactivity of reagents or catalysts

• Generation of useful reactive species

We need to customize according to your working conditions, liquid information, throughput, and spatial information....

So, before qutation, we may ask for many information about your application, like :

what's the liquid you dealing with?

what's the Temperature, pressure under work?

what's the capacity?

what's the inatll enviroment?

....

We have customized more than hundred ultrasonic liquid processing for different application.