20Khz Ultrasonic Water Treatment System Sonochemical Reaction

What's the theory of ultrasonic sonochemistry?

Sonochemistry, i.e. the chemical effects of ultrasound, originates in acoustic cavitation: nucleation, growth and implosion of gas bubbles in liquids submitted to an ultrasonic field. The implosion occurs on the microsecond time scale and the collapse induces extreme local conditions of several thousand degrees and several hundred of bar pressure, with high cooling rates (~1010 K s-1). Recent studies demonstrated the formation of non-equilibrium plasma inside the bubble at collapse. This local concentration of energy constitutes the origin of the light emission by the cavitation bubbles (sonoluminescence), of the chemical activity in the bulk and of the evolution of heterogeneous systems. Each cavitation bubble, having for example a resonance size of ~150 μm at 20 kHz, can be considered as a high-temperature microreactor allowing physico-chemical reactions to occur. It does not need specific reactants to be added and does not generate additional wastes, hence adhering to the "green chemistry" principles.

Ultrasound can be used in chemistry to increase both reaction rates and yields of products. Most effects of ultrasound on chemical reactions are due to cavitation: the formation and collapse of small bubbles in the solvent. In this review, we first outline the physical background of cavitation, and discuss its dependence on factors such as sound intensity and frequency, solvent and temperature. The impact of ultrasound on chemical reactions is considered for homogeneous reactions and for heterogeneous liquid‐solid systems. The first area is mainly illustrated by a discussion of the effect of ultrasound on polymerization and depolymerization reactions, the second by selected examples in organic synthesis. The tendency of ultrasound to change reaction mechanisms in favour of homolytic (instead of heterolytic) pathways, is also briefly discussed. The specific preference for a particular pathway under sonochemical conditions, different from that under mechanical stirring has been termed “sonochemical switching”. Ultrasonic equipment for lab‐scale experiments are compared, and some practical “tricks and traps” are given.

Parameter

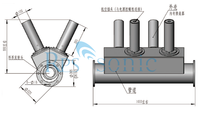

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Application:

• Cell disrupter (extraction of plant substances, disinfecting, enzyme deactivation)

• Therapeutic ultrasound, i.e. induction of thermolysis in tissues (cancer treatment)

• Decrease of reaction time and/or increase of yield

• Use of less forcing conditions e.g. lower reaction temperature

• Possible switching of reaction pathway

• Use of less or avoidance of phase transfer catalysts

• Degassing forces reactions with gaseous products

• Use of crude or technical reagents

• Activation of metals and solids

• Reduction of any induction period

• Enhancement of the reactivity of reagents or catalysts

• Generation of useful reactive species

We need to customize according to your working conditions, liquid information, throughput, and spatial information....

So, before qutation, we may ask for many information about your application, like :

what's the liquid you dealing with?

what's the Temperature, pressure under work?

what's the capacity?

what's the inatll enviroment?

....

We have customized more than hundred ultrasonic liquid processing for different application.