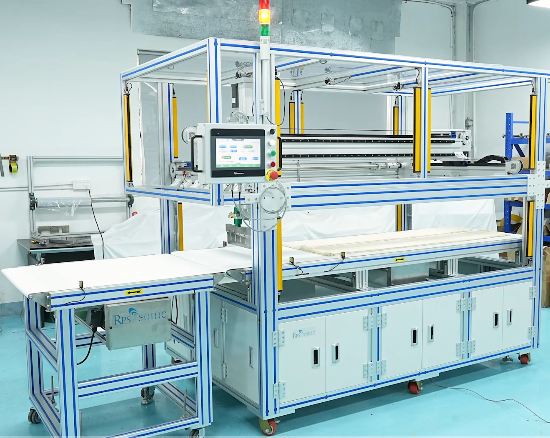

Ultrasonic Food Cutting Technology with Conveyor Belt

Ultrasonic conveyor belt food cutting systems are automated cutting solutions for foods such as cakes, pizzas, and sandwiches. Suitable for large-scale production, they use high-speed vibrations to achieve fast, precise, and residue-free cuts. Choosing the right equipment depends on specific needs, such as the type of food being processed, production volume, and cutting accuracy.

What is ultrasonic food cutting?

Ultrasonic food cutting does not directly cut using sound waves, but rather utilizes high-frequency mechanical vibrations. At its core, an ultrasonic generator converts ordinary 50/60Hz electrical energy into high-frequency energy of 20,000Hz (20kHz) or higher. This energy is then converted to mechanical vibrations of the same frequency by a transducer.

These tiny mechanical vibrations are amplified by a metal blade called a "knife head" or "anvil." Vibrating at a frequency of over 20,000 times per second, the blade cuts food with exceptional efficiency and cleanliness.

How it works: Why does it cut so perfectly?

Traditional cutting relies on downward pressure and a sharp cutting edge to "cleave" the material, while ultrasonic cutting uses "vibratory micro-cutting."

High-frequency, low-amplitude vibration: The blade generates extremely rapid vibrations in the cutting direction (usually vertically), with an amplitude of only tens of microns, tens of thousands of times per second. This amplitude is barely visible to the human eye.

Energy Localization: The enormous vibration energy is highly concentrated within a very small area of the blade's cutting edge.

Friction Reduction: The contact between the blade and the food material is instantaneous and high-frequency, significantly reducing static friction and adhesion. The blade does not "drag" the food, but rather "glides" across it with ease.

Brittle Fracture Effect: For many materials (especially those containing water, soft materials, and easily deformable materials), this high-frequency vibration can cause them to lose their toughness in localized areas, causing them to behave like brittle materials, resulting in clean separation rather than crushing and deforming.

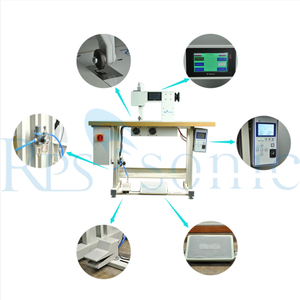

System Components

A complete ultrasonic conveyor belt food cutting system typically includes:

Ultrasonic generator: The "brain" of the system, providing and controlling high-frequency electrical energy.

Transducer: Converts electrical energy into mechanical vibrations.

Amplitude modulator: Also known as a horn, amplifies the vibration amplitude generated by the transducer and transmits it to the cutter head.

Cutting head: The component that directly performs the cutting task. Available in various shapes (flat, round, or lace blades) to suit different products.

Conveyor system: Precisely transports food to the cutting station.

Control system: Integrated with a PLC or computer, coordinates ultrasonic power, cutting speed, cutting depth, and conveyor speed.

Highlights

Ultrasonic cutting offers revolutionary advantages over traditional blade cutting:

Advantages Specific Application Examples

1. Perfect, clean cut surfaces: No debris, deformation, stringing, or smearing. Products are cut smoothly, showcasing their rich interior. Examples include cakes, cheese, jelly, mousse, soft candy, and filled products.

2. No product sticking: High-frequency vibrations prevent wet, greasy, or sticky products from sticking to the blade. Examples include toffee, frozen pizza, rice cakes, candied fruit, and sticky cheese.

3. High precision and consistency: Extremely precise and consistent cutting is achieved regardless of product shape, reducing waste. Cut products into specific shapes (such as diamonds or wavy shapes) or divide them equally.

4. Extended Equipment Life: Low cutting resistance and extremely slow blade wear make sharpening virtually unnecessary, significantly reducing maintenance costs and downtime. Suitable for all food production lines requiring frequent cutting.

5. Hygiene and Safety: The cutting process itself generates very little heat, which has a certain sterilizing effect. It leaves no product residue, is easy to clean, and complies with HACCP standards. Suitable for meat, dairy, and ready-to-eat foods with extremely high hygiene requirements.

6. Multi-Layer Cutting: Products made from multiple layers of different materials (such as puff pastry, cream, and fruit) can be perfectly cut in one go without causing shifting or collapsing between layers. Examples include Napoleon cakes, fruit tarts, sandwiches, and hamburgers.

Applications: Ultrasonic cutting technology is widely used in the following food categories:

Bakery and Confectionery: Cakes, bread, pies, mousses, fudge, nougat, and chocolate-coated products.

Dairy: Various hard, semi-hard, and soft cheeses, butter, and frozen yogurt blocks.

Fruits and Vegetables: Precision cutting of fruit bars, vegetable rolls, and jellies.

Meat and Seafood: Uniformly cut meatloaf, sausages, fish fillets, and sushi rolls.

Ready Meals and Convenience Foods: Pizza, sandwiches, energy bars, and protein bars.

Future Development Trends

Intelligence and Integration: Deep integration with machine vision, robotics, and AI enables "adaptive cutting" that automatically identifies product position and adjusts the cutting path.

Customized Cutting Head Solutions: Develop more sophisticated and efficient customized cutting heads for specific products and needs.

Cost Optimization: With the popularization of technology and the large-scale production of core components, equipment costs are expected to gradually decrease, making them accessible to more small and medium-sized enterprises.

New Material Applications: Exploring more wear-resistant and efficient transducer and cutting head materials to expand its application range.

Summary

Ultrasonic conveyor belt food cutting technology is one of the key technologies for the modern food industry to move towards high-end, refined, and automated processing. By applying high-frequency mechanical vibration to the cutting process, it fundamentally solves the many challenges faced by traditional cutting methods when processing soft, sticky, and multi-layered composite foods. This achieves "lossless," "stick-free," "high-quality," and "efficient" cutting, significantly increasing product value and the level of automation in production lines. While limited by cost and applicability, the resulting quality improvements and comprehensive benefits make it irreplaceable in the high-value food processing sector.