Ultrasonic Chocolate Cutting Technology

Ultrasonic chocolate cutting is a technology that uses high-frequency mechanical vibrations to cut chocolate. Instead of "sawing" or "pressing" the chocolate, it applies tiny vibrations at a frequency of 20,000 times per second (20kHz) or higher to the cutting blade or cutter, using this vibrational energy to cleanly separate the chocolate.

How it Works:

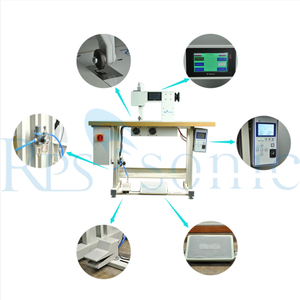

Energy Conversion: At the heart of the device is an ultrasonic generator (power source) and a transducer (energy converter). The generator converts a standard 50/60Hz low-frequency current into a high-frequency (typically 20kHz - 40kHz) electrical signal.

Vibration Generation: The transducer (usually based on the piezoelectric ceramic effect) receives the high-frequency electrical signal and converts it into mechanical vibrations of the same frequency.

Amplification: These tiny mechanical vibrations are amplified by a metal component called an amplitude transformer. The amplitude transformer is carefully designed to amplify the vibration amplitude to a level sufficient for effective cutting.

Transmission to the Blade: The amplified vibrations are transmitted to the cutting blade or cutter mounted at the front end. At this moment, while the blade is making a linear cutting motion, it is also vibrating at an extremely high frequency with micro-amplitude.

Cutting Process: When the high-speed vibrating blade comes into contact with the chocolate:

Microscopic "Hammering": The vibrational energy generates enormous acceleration and stress at the contact point between the blade and the chocolate, instantly "shattering" the chocolate's crystalline structure at a microscopic level, rather than crushing it with immense pressure.

Reduced Friction: The vibration makes the contact between the blade and the chocolate intermittent, greatly reducing friction and adhesion.

Clean Separation: The result is that the chocolate is cut cleanly and neatly, with almost no debris, and the cut is as smooth as a mirror.

Technological Advantages (Why is it superior to traditional cutting?) Compared to traditional methods that rely on pressure or wire cutting, ultrasonic cutting has overwhelming advantages:

No debris, no cracks: Because it is "vibration separation" rather than "pressure crushing," almost no debris is generated during the cutting process, and it does not cause micro-cracks in delicate chocolate bars or coatings.

Extremely Smooth Cut: The cut surface is very flat and smooth, with an exquisite appearance, greatly enhancing the product's premium feel and quality. High Precision and Complex Shapes: Easily and precisely cuts highly complex and intricate patterns, including chocolates with fillings and nuts, without causing deformation or chipping.

High Efficiency and Long Lifespan: Low cutting resistance allows for increased cutting speed. Simultaneously, low friction significantly reduces blade wear, resulting in a longer lifespan.

Hygienic and Clean: No debris means easier cleaning, meeting high hygiene standards in food production. The vibration itself also has a self-cleaning effect.

Suitable for Various Conditions: It excels whether cutting solidified chocolate blocks, slicing chocolate bars online on a conveyor belt, or trimming the edges of chocolate products.

Application Scenarios: Ultrasonic cutting technology is primarily used in high-end and industrial chocolate production:

Chocolate Bar Slicing: Efficiently and precisely slices large chocolate slabs into individual chocolate bars.

Fishing of Filled Chocolates: Perfectly cuts chocolates with molten fillings such as soft centers, caramel, and jam, ensuring the filling doesn't stick to the blade, doesn't overflow, and produces clean cuts.

Chocolate Decorator Making: Used to create highly delicate and fragile chocolate rolls, chocolate chips, and other decorations.

Chocolate Coating Refining: Precisely cuts and trims the chocolate coating on cakes and ice cream.

Personalized and Customized Chocolates: Works with automated systems to precisely cut complex patterns and text, meeting personalized customization needs.

Summary: Ultrasonic chocolate cutting technology represents a significant upgrade in the chocolate processing industry. By introducing high-frequency vibrations, it fundamentally changes the physical process of cutting, achieving a leap in quality, precision, and efficiency.

While not yet widespread in all chocolate factories due to its cost, this technology has become a key tool for manufacturers pursuing top quality, high-value-added products, and efficient automated production, enhancing competitiveness and creating differentiated products. It perfectly illustrates how engineering technology can transform ordinary food processing into a precise art.