Ultrasonic Cake Cutting Technology

Similar to chocolate cutting, ultrasonic cake cutting technology is also an advanced process that utilizes high-frequency mechanical vibration for cutting. However, because cakes (especially those containing cream, fruit, cheese, etc.) are physically very different from chocolate, this technology brings unique, even revolutionary, advantages to the cake industry.

Core Challenges: Why is cutting cakes traditionally difficult?

Traditional knife cutting of cakes, especially delicate pastries, encounters the following problems:

Stickiness and Sludge: Soft materials such as cream, frosting, cheese, and jam stick to the blade, resulting in unclean cuts. Cleaning is required after each cut, making it extremely inefficient.

Compression and Deformation: The downward cutting pressure compresses the cake, causing deformation and disrupting its layered structure.

Crust Problems: Dry cake crumbs scatter, contaminating fillings and cream layers.

Rough Cuts: A clean, smooth, and aesthetically pleasing cut cannot be obtained, affecting the product's appearance.

How Does Ultrasonic Technology Solve These Problems?

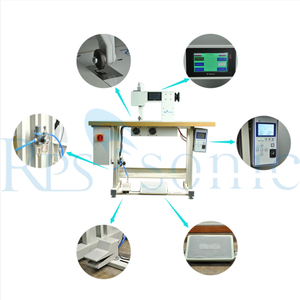

An ultrasonic cake cutting system also consists of an ultrasonic generator, transducer, amplitude transformer, and cutting blade. Its working process is similar to cutting chocolate, but its core mechanism is more prominent when working with cakes:

Energy Transfer and "Non-Stick" Cutting:

The high-frequency vibrating blade instantly transfers vibrational energy to the soft filling upon contact.

This vibration creates a "micro-vibrational layer" between the blade surface and the food, greatly reducing the contact area and intermolecular adhesion.

Result: Cream, cheese, and other ingredients are almost completely non-stick, achieving unprecedentedly clean cuts.

Low-Temperature Cutting Effect:

Vibrational energy generates slight localized heat, but more importantly, the rapid vibration reduces the contact time between the blade and the food, preventing heat buildup due to friction.

This makes it ideal for cutting temperature-sensitive ingredients (such as cream and ice cream cakes), preventing them from melting.

"Pressure-Free" Separation:

Cutting relies primarily on vibrational energy to separate ingredients, rather than on immense downward pressure.

Result: Cake layers are not flattened, maintaining their fluffy structure and beautiful layers.

Technical Advantages Summary

Perfectly Flawless Cuts: Smooth, clean cuts perfectly showcase the internal layers of cakes (such as rainbow cakes, mousse cakes, and mille-feuille cakes), greatly enhancing the product's aesthetics and perceived value.

Ultimate Cleanliness, No Frequent Wiping Required: Completely eliminates the sticking problem, allowing for the continuous cutting of hundreds of cakes without blade cleaning, making it ideal for automated production lines.

Maintaining Product Structure: The near-zero pressure cutting method ensures that soft cakes and delicate pastries do not deform or collapse.

High Hygiene Standards: Reduces contact and contamination with the product, while the vibration itself also has a secondary effect of inhibiting microbial growth (though not the primary function), better complying with HACCP standards.

Versatility: The same ultrasonic cutter can easily handle a variety of products, from soft sponge cakes to hard frozen cakes, from moist cheesecakes to crisp Napoleon cakes.

Application Scenarios

This technology plays a significant role in the following scenarios:

High-End Pastry Industrial Production: Used for precise cutting of mousse cakes, cheesecakes, tiramisu, etc., ensuring that each product has a consistent and perfect appearance.

Slicing Swiss Rolls: Cleanly and precisely slices Swiss rolls with fillings, preventing spillage and creating smooth cuts.

Ice Cream Cake Slicing: Enables clean cutting even when frozen, preventing melting of the ice cream or cracking of the cake.

Uniform Slicing of Baked Goods: Efficiently and accurately slices large baking pan cakes into uniformly sized pieces.

New Product Development: Provides technological possibilities for creating new pastries with complex layers and exquisite appearances.

Conclusion: Ultrasonic cake cutting technology is not merely a cutting tool, but a solution for quality and efficiency. It solves the most challenging problems in traditional pastry cutting, enabling perfectly sculpted cuts comparable to handcrafted works of art even in industrialized production environments.

For modern baking and pastry manufacturers seeking high quality, high efficiency, and high consistency, this technology is gradually transforming from a "high-end option" into an "essential tool" for enhancing core competitiveness. It represents a significant development direction in the field of automated baking food processing.