Typical Application of Automatic Welding in Automobile Field

纵观整个汽车工业的焊接现状,不难分析出汽车工业的焊接发展趋势为:发展自动化柔性生产系统。而工业机器人,因集自动化生产和灵活性生产特点于一身,故轿车生产近年来大规模、迅速地使用了机器人。在焊接方面,主要使用的是点焊机器人和弧焊机器人。特别是近几年,汽车生产企业非常重视焊接的自动化。如一汽引进的捷达车身焊装车间的13条生产线的自动化率达80%以上,各条线都由计算机(可编程控制器PLC-3)控制,自动完成工件的传送和焊接。焊接由R30型坐标式机器人和G60肘节式机器人共61台进行,机器人驱动由微机控制,数字和文字显示,磁带记录仪输入和输出程序。机器人的动作采用点到点的序步轨迹,具有很高的焊接自动化水平,既改善了工作条件,提高了产品质量和生产率,又降低材料消耗。

Looking at the welding status of the whole automotive industry, it is not difficult to analyze the welding development trend of the automotive industry as follows: the development of automated flexible production system. Industrial robots, due to the characteristics of automation and flexible production, have been widely and rapidly used in car production in recent years. In the field of welding, spot welding robots and arc welding robots are mainly used. Especially in recent years, automobile manufacturers attach great importance to welding automation. For example, the automation rate of 13 production lines of JETA body welding workshop imported by FAW is over 80%, and each line is controlled by computer (programmable controller PLC-3), which can automatically complete the transmission and welding of workpieces. The welding is carried out by 61 R30 coordinate robots and G60 elbow robots. The robot drive is controlled by a computer, and the input and output programs of the tape recorder are displayed numerically and literally. The robot adopts point-to-point sequential trajectory, which has a high level of welding automation. It not only improves working conditions, improves product quality and productivity, but also reduces material consumption.

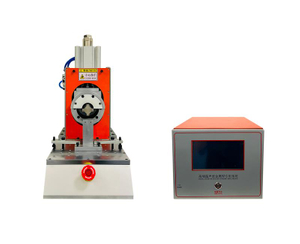

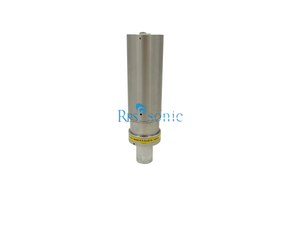

超声波汽车焊接设备主要应用于汽车车门焊接、汽车汽车仪表焊接、车灯车镜焊接、遮阳板焊接、内饰件焊接、滤清器焊接,反光材料焊接、反光道钉焊接、保险杠焊接、拉索焊接、摩托车用塑料滤清器焊接、散热器焊接、制动液罐焊接、油杯焊接、水箱焊接、油箱超声波焊接、风管超声波焊接、尾气净化器超声波焊接、托盘滤板超声波焊接等等。

Ultrasonic automobile welding equipment is mainly used in automobile door welding, automobile instrument welding, automobile lamp mirror welding, sunshade welding, interior decoration welding, filter welding, reflective material welding, reflective track nail welding, bumper welding, cable welding, motorcycle plastic filter welding, radiator welding, manufacturing. Dynamic tank welding, oil cup welding, water tank welding, oil tank ultrasonic welding, wind pipe ultrasonic welding, tail gas purifier ultrasonic welding, tray filter plate ultrasonic welding and so on.

Application Trend of Welding Robot in Automotive Industry

随着汽车工业的发展和对自动化水平要求的不断提高,为焊接机器人市场的快速增长提供了一个良好的机会。预计国内企业对焊接机器人的需求量将以30%以上的速度增长。从机器人技术发展趋势看,焊接机器人不断向智能化方向发展,完美实现生产系统中机器人的群体协调和集成控制,从而达到更高的可靠性和安 性。而采用焊接机器人的汽车生产企业在高技术、高质量、低成本条件下必将获得高速发展,也必将为汽车产业的发展带来新的生机。

With the development of automobile industry and the continuous improvement of automation level, it provides a good opportunity for the rapid growth of welding robot market. It is expected that the demand for welding robots will increase by more than 30% in domestic enterprises. From the perspective of the development trend of robotics technology, welding robots continue to develop in the direction of intellectualization, perfectly realizing the group coordination and integrated control of robots in the production system, so as to achieve higher reliability and security. The automobile manufacturing enterprises using welding robots will surely achieve rapid development under the conditions of high technology, high quality and low cost, and will also bring new vitality to the development of the automobile industry.

Ultrasonic welding characteristics:

- 焊接速度快,焊接强度高、密封性好;

- The welding speed is fast, the welding strength is high and the sealing is good.

- 取代传统的焊接/粘接工艺,成本低廉,清洁无污染且不会损伤工件;

- Instead of the traditional welding/bonding process, it has the advantages of low cost, clean, pollution-free and no damage to the workpiece.

- 焊接过程稳定,所有焊接参数均可通过软件系统进行跟踪监控,一旦发现故障很容易进行排除和维护。

- The welding process is stable. All welding parameters can be tracked and monitored by software system. Once the faults are found, they can be easily removed and maintained.

Other Applications of Ultrasonic Welding

手套箱

Glove box

材料:PP

Material: PP

特点:可以取代使用螺钉、钉扣和其他辅助焊接物;外观好。应用 新振动摩擦焊接工艺可以避免传统热板焊接中出现的零件变形和表面收缩。

Features: It can replace the use of screw, screw fastener and other auxiliary welding materials; good appearance. The application of new vibration friction welding technology can avoid the deformation and surface shrinkage of parts in traditional hot plate welding.

进气歧管

Intake manifold

材料:尼龙

Material: nylon

特点:提高气密性,可以提高发动机性能;塑料代替铝可有效降低重量、零件制造成本和投资成本。

Features: Improving air tightness can improve engine performance; Replacing aluminum with plastic can effectively reduce weight, manufacturing cost and investment cost of parts.

仪表盘

Dashboard

材料:ABS

Material: ABS

特点:强度高、密封性好;不需使用钉扣、粘结剂等辅助物;可以免除刮伤 仪表盘镜片。

Features: High strength, good sealing; no need to use nails, adhesives and other auxiliary materials; can avoid scratching instrument panel lenses.

汽车尾灯

Automobile taillight

材料:ABS和丙烯酸树脂(Acrylic)

Materials: ABS and Acrylic

特点:水密性高,强度好,焊接线清晰美观,应用振动摩擦焊接工艺可以有效避免传统热板焊接造成的透明材料的变色。

Features: High water tightness, good strength, clear and beautiful welding line, the application of vibration friction welding process can effectively avoid the discoloration of transparent materials caused by traditional hot plate welding.

汽车门板

Automobile door panel

材料:PP

Material: PP

特点:代替钉扣,可靠性强;有效降低成本;并避免运动途中的振动声响。

Features: instead of nails, it has strong reliability; effectively reduces costs; and avoids vibration and noise in the course of sports.

轮胎橡胶切割

Tire rubber cutting

特点:切削面光滑、粘性好,防止切割面硫化,无粉尘,无异味

Features: Smooth cutting surface, good stickiness, prevent vulcanization of cutting surface, no dust, no odor.