Semiconductor Endoscope Ultrasonic Spray Coating Technology

This is a high-end manufacturing technology integrating precision mechanics, semiconductor processing, and medical materials science.

I. Core Technology: Why Use Ultrasonic Spray Coating? Traditional endoscope protection may use immersion or ordinary spraying, but these methods have fatal flaws for semiconductor endoscopes (especially front-end CMOS/CCD sensors), which are worth hundreds of thousands of dollars and have delicate structures:

Uneven coating: Leading to image distortion or ripples.

Excessive material waste: A large amount of expensive medical coating is wasted.

Potential device damage: Liquid drips or seeps into non-target areas.

Ultrasonic spray coating technology perfectly solves these problems:

Different atomization principle: High-frequency ultrasonic vibration (typically 20kHz-120kHz) "tears" the liquid into micron/micron particles. Nanoscale fine droplets, rather than relying on high-pressure gas, result in:

Extremely low atomization pressure: a gentle liquid flow without splashing or bouncing.

Uniform droplet size: ensuring highly consistent coating thickness.

Precise flow control: enabling extremely thin (hundreds of nanometers) and uniform coatings.

Superior processing effects:

High uniformity: forming defect-free films on complex sensor and lens surfaces.

High conformality: perfect coverage even on surfaces with minute irregularities.

Extremely high material utilization: exceeding 90%, saving on expensive functional coatings.

Non-contact: avoiding physical contact damage to precision semiconductor components.

II. Key Technical Aspects and Processes A complete ultrasonic spray coating system for semiconductor endoscopes typically includes the following components:

1. 1. Pre-treatment and Cleaning

The endoscope tip module must undergo rigorous cleaning and plasma treatment. Plasma treatment activates the workpiece surface, increases coating adhesion, and removes microscopic contaminants.

2. Precision Positioning and Masking

A high-precision robotic arm or motion platform is used to precisely control the relative movement between the endoscope and the ultrasonic nozzle.

Non-coating areas (such as metal casings and connection points) require physical masking to ensure the coating only covers the optical glass and sensor areas.

3. Ultrasonic Spraying Process

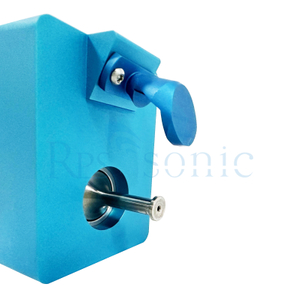

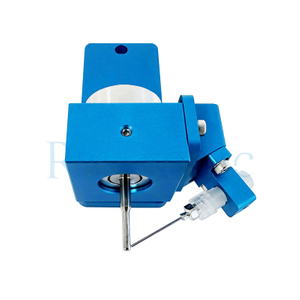

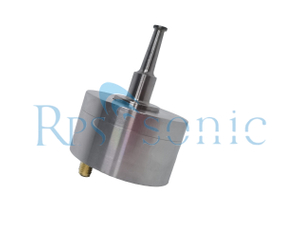

Nozzle: The core component, converting electrical signals into mechanical vibrations, generating ultrasonic waves at the nozzle tip, causing the outflowing liquid to form a uniform micro-mist.

Liquid Supply System: Precisely controls the delivery speed and total volume of the coating liquid, typically achieved by a precision injection pump or liquid chromatography pump.

Motion Control: Programmably controls the nozzle path, ensuring that every part of the sensor and lens receives an equal amount of spray. This is usually multi-axis linkage.

4. Curing and Post-treatment

After spraying, curing is required. The curing method depends on the chemical properties of the coating and can be:

Thermal curing: Low-temperature heating in an oven (to avoid damaging semiconductors).

UV curing: For UV-cured coatings.

Room temperature curing: Natural air drying.

5. Quality Inspection

Optical Inspection: Inspect the coating for defects, bubbles, or impurities.

Thickness Measurement: Measure the coating thickness using non-contact equipment such as a white light interferometer or ellipsometer to ensure it meets specifications (typically at the micrometer level).

Functional Testing: Conduct waterproofing and stain resistance tests, and check in a simulated environment whether image quality is degraded due to the coating.

III. Types of Functional Coatings Applyed This is where the value of this technology lies; it's not ordinary paint, but a thin film with specific functions:

Hydrophobic/Oleophobic Antifouling Coating:

Materials: Fluorinated polymers (such as PTFE), modified silanes.

Function: Prevents the adhesion of blood, tissue fluid, and proteins, keeping the mirror clean and ensuring a clear field of vision. This is the core coating.

Antireflective Coating:

Materials: Multilayer metal oxides (such as SiO₂, ... TiO₂).

Function: Reduces light reflection on the lens surface, increases light transmittance, and improves image contrast and brightness.

Biocompatibility Coating:

Materials: Medical-grade silicone, phospholipid polymers.

Function: Ensures safety when the device comes into contact with human tissue, reducing rejection reactions and tissue damage.

Hydrophilic Lubricating Coating:

Materials: Polyvinylpyrrolidone (PVP), etc.

Function: Typically applied to the outer wall of the insertion tube to reduce frictional resistance during insertion into the body, improving patient comfort.

item | Traditional methods | ultrasonic spraying technology |

Coating uniformity | Average, prone to orange peel and dripping | Excellent, nanometer-level precision control. |

Material utilization rate | Low (30%-60%) | High (>90%) |

Impact on workpiece | May cause damage due to high pressure or liquid impact. | Non-contact, gentle, and non-damaging. |

Complex shape coverage | Poor, many blind spots | Excellent, good shape retention |

Process controllability | Low | Extremely high, digital programming control |

Coating thickness | Thicker, harder to control | Ultra-thin, with precision down to the submicron level |

V. Applications and Future Prospects

Current Applications: Primarily used in the manufacture of high-end endoscopes such as disposable duodenoscopes, bronchoscopes, and colonoscopes, as well as the remanufacturing and repair of reusable endoscopes.

Future Trends:

Multifunctional Composite Coatings: Multiple layers of coatings with different functions are sequentially sprayed onto the same surface (e.g., antireflective coating followed by hydrophobic coating).

Intelligentization and AI Integration: Utilizing machine vision to automatically identify the spraying area and optimizing the spraying path and parameters through AI algorithms.

New Material Development: Such as "self-healing" coatings that automatically repair minor scratches; or drug-loaded coatings that release therapeutic drugs during examination.

In conclusion, ultrasonic spraying technology for semiconductor endoscopes is one of the key manufacturing processes ensuring the high performance, high reliability, and safety of modern precision medical endoscopes, and is a jewel in the crown of high-end medical device manufacturing.