Spraying technology, as a surface treatment method, is widely present in material testing, research, and industrial production. With the continuous improvement in surface requirements and environmental awareness, some traditional spraying methods may no longer meet product demands. In such cases, precision ultrasonic spraying can be attempted. So, what circumstances can prompt a change to ultrasonic spraying?

Ultrasonic spraying, as a form of precise spraying, offers significant advantages: uniformity, precision, and material savings. It is a unique spraying technique based on ultrasonic atomization technology. The material to be sprayed is initially in liquid form, which can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by the ultrasonic atomizer, followed by uniform application with a certain amount of carrier gas (≤0.15MPA). Coating is applied to the relative surface of the substrate to form a layer or film.

Conventional spraying often uses high-speed airflow to disperse liquid material and spray it onto the substrate. Achieving the effects of ultrasonic spraying with conventional techniques can be challenging in terms of professionalism and accuracy. Additionally, material waste due to paint splatter during spraying is a common issue.

In comparison to traditional spraying techniques, ultrasonic spraying offers the following advantages:

1. More uniform coating distribution: Ultrasonic spraying produces finer and more uniform liquid droplets, facilitating even coating distribution and enhancing coating quality.

2. Higher coating adhesion: The fine liquid droplets generated by ultrasonic spraying adhere better and spread more effectively on the target surface, increasing coating adhesion.

3. Reduced overspray and splatter: The production of fine liquid droplets by ultrasonic spraying leads to reduced overspray and splatter, minimizing material waste and environmental pollution.

4. Improved spraying efficiency: Ultrasonic spraying technology enhances spraying efficiency, reducing liquid material consumption and saving production costs.

5. Suitability for high-viscosity liquids: Ultrasonic spraying can effectively handle high-viscosity liquids, making spraying more flexible and reliable.

6. Non-contact spraying: Ultrasonic spraying is typically a non-contact spraying technique, avoiding surface damage or deformation caused by contact.

7. Capability for nanoparticle spraying: Ultrasonic spraying technology can be used for nanoparticle spraying, enabling precise control of surface features and the preparation of functional coatings.

8. Wider range of application fields: Ultrasonic spraying technology finds diverse applications in coating, nanoparticle spraying, printing, biomedicine, electronics manufacturing, and more, showcasing its versatility.

Overall, ultrasonic spraying technology offers superior coating uniformity, adhesion, spraying efficiency, and applicability compared to traditional spraying techniques, making it an efficient and precise spraying method widely used across various industries.

In contrast to conventional spraying techniques, ultrasonic spraying has advantages in terms of precision, which is one of the reasons why ultrasonic precision spraying is increasingly applied.

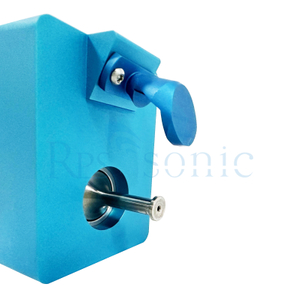

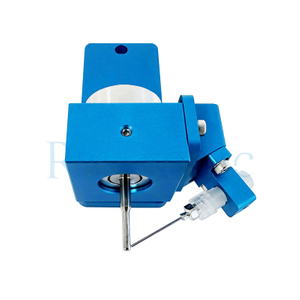

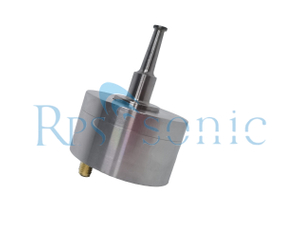

Different from traditional nozzles that rely on pressure and high-speed movement to break liquid into small droplets, ultrasonic nozzles use lower ultrasonic vibration energy to atomize liquids. Ultrasonic precision spraying is a form of atomizing spraying. When the liquid substance leaves the nozzle, it has already been atomized into uniformly distributed fine particles. Only micro-gas with a pressure ≤0.15MPA can be transported to the substrate surface to form a coating or film. Due to the low pressure of the carrier gas, paint splatter during spraying is significantly reduced, achieving the goal of saving paint. The paint utilization rate of ultrasonic spraying is more than four times that of traditional dual-fluid spraying.

Moreover, the nozzle of the ultrasonic precision spraying machine is made of titanium alloy, known for its high strength and corrosion resistance. In theory, there are no limitations on the properties of liquid materials, but through extensive testing, currently only liquid materials with a viscosity less than 50cps and solid content less than 20-30% can be atomized.

Ultrasonic spraying technology utilizes the mechanical vibration of ultrasonic waves to achieve the spraying process. In this technique, ultrasonic waves generate fine liquid droplets within the liquid nozzle through vibration, which are then sprayed onto the target surface. During the descent of the liquid droplets, the vibrational effect of the ultrasonic waves aids in the even dispersion and adhesion of the liquid droplets.

Ultrasonic spraying technology has a wide range of applications, including but not limited to the following areas:

· Coating preparation: Ultrasonic spraying technology can be used for preparing thin film coatings, such as ceramic coatings, metal coatings, etc., with high uniformity and adhesion.

· Nanomaterial spraying: Used to evenly spray nanoparticles and nanomaterials onto the surface of base materials, widely applied in the field of nanotechnology.

· Coating and painting: Ultrasonic spraying can be used in automotive painting, furniture painting, etc., to achieve efficient and uniform coating effects.

· Printing industry: In the printing field, ultrasonic spraying technology can be used for spraying inks, pigments, etc., improving printing quality and efficiency.

· Biomedical applications: Used for preparing drug coatings, medical coatings, etc., to achieve controlled drug release and targeted delivery.

· Electronics industry: Ultrasonic spraying technology can be used for thin film coating and optical film coating in semiconductor manufacturing applications.

· Protective coatings: Applied in fields such as anticorrosive coatings, waterproof coatings, etc., enhancing coating durability and protection.

· Food industry: Ultrasonic spraying can be used for food packaging coatings, food processing, etc., to achieve surface coating and treatment.

In summary, ultrasonic spraying technology is widely used in coating preparation, nanomaterial spraying, coating and painting, printing industry, biomedical applications, electronics manufacturing, protective coatings, and the food industry, playing a crucial role in improving coating quality, adhesion, and production efficiency across various sectors.

English

English