Ultrasonic spraying technology is used to apply an ultra-thin, uniform coating to the inner wall of an insulin pen's storage container (also known as a cartridge or refill). This process is a typical application of precision coating for medical devices.

I. Why spray-coat insulin cartridges?

Insulin is a protein-based drug that is very sensitive to surface interactions. The main purposes of coating are:

Reducing adsorption: Preventing insulin solution from adhering to the inner wall of glass or plastic ensures accurate dosing with each injection. Even trace amounts of adsorption can lead to reduced efficacy and inaccurate dosing.

Enhancing lubricity: Enabling the rubber piston to move the drug more smoothly, reducing friction and ensuring consistent drug delivery.

Improving stability: Certain coatings (such as siliconization) can create an inert surface, reducing the risk of chemical reactions between insulin and packaging materials, and extending the shelf life of the drug.

Preventing foaming: A uniform coating can reduce the formation of bubbles in the drug solution during filling or use.

II.Why Ultrasonic Spray Technology?

Ultrasonic spray offers significant advantages over traditional pneumatic or two-fluid spraying for precision applications such as these:

Ultrasonic spraying features:

Extremely high uniformity. Produces monodisperse micron/nano-sized droplets, resulting in extremely thin (down to submicron), defect-free films.

Coating thickness is precisely controllable. Parameters such as flow rate and nozzle speed can be precisely adjusted, saving paint.

Gentle atomization: Utilizing high-frequency acoustic vibrations to "tear" the liquid into a fine mist, it eliminates the need for high-pressure gas and produces no shock or shear stress on the liquid.

High transfer efficiency (typically >85%), excellent droplet directionality, minimal overspray, and reduced waste, resulting in a more environmentally friendly process.

Excellent consistency: Digitally controlled process parameters minimize batch-to-batch variability, meeting the stringent GMP requirements for medical devices.

III. Core Components of an Ultrasonic Spray Coating System

An ultrasonic system for spray coating insulin cartridges typically includes the following:

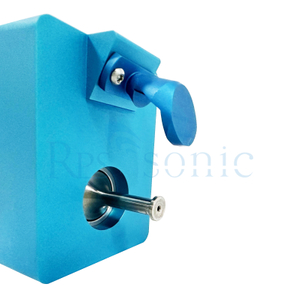

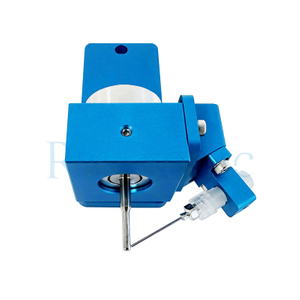

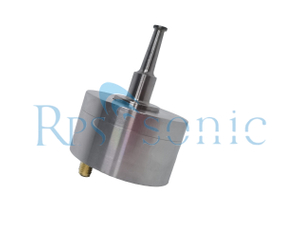

Ultrasonic spray nozzle: The core component converts high-frequency electrical signals into mechanical vibrations, generating capillary waves at the nozzle tip, atomizing the liquid.

Dosing pump: A high-precision peristaltic pump or syringe pump, used to deliver the coating solution (such as silicone oil) to the spray nozzle at a stable and precise flow rate.

Motion control system: Typically a multi-axis robotic arm or precision turntable. This precisely controls the spray nozzle's motion relative to the insulin cartridge, ensuring uniform 360° coverage of the inner wall.

Atomization chamber/fume hood: An enclosed or semi-enclosed environment used to collect excess spray droplets, ensuring safe operation and a clean working environment.

Control system: Integrated software used to set and store all process parameters (frequency, flow rate, movement speed, path, etc.).

Typical Spray Coating Process

Pretreatment: Insulin cartridges (usually glass cartridges) undergo rigorous cleaning, drying, and (optionally) plasma treatment to ensure a clean surface and enhance coating adhesion.

Coating Solution Preparation: The coating material (e.g., medical-grade silicone oil) is diluted in a suitable solvent (e.g., n-heptane) to form a uniform solution.

Spraying: A robotic arm precisely positions the spray nozzle at the opening of the insulin cartridge.

The spray nozzle is activated, and the robotic arm guides the nozzle along a specific path (e.g., a spiral motion from top to bottom) to ensure uniform deposition of the atomized droplets across the entire interior surface.

The entire process is completed in seconds.

Curing: The coated insulin cartridges are conveyed into a drying oven or curing tunnel where the solvent evaporates, leaving behind an ultra-thin, durable coating film.

Inspection and Quality Control: Coating quality is fully inspected or sampled using methods such as high-magnification microscopy, gravimetric methods (to check coating weight), and contact angle measurement (to check hydrophobicity).

Assembly and sterilization: The coated insulin cartridge is assembled with components such as the rubber piston, and then sterilized (such as by ethylene oxide or gamma ray sterilization) before use.

V. Technical Challenges and Considerations

Coating Material Selection: Medical-grade materials (such as high-purity silicone oil) with high biocompatibility and no impact on insulin stability must be used.

Dust-Free Environment: The entire spraying and curing process must be performed in a cleanroom to prevent particulate contamination.

Process Validation: Extremely stringent process validation (IQ/OQ/PQ) is required to demonstrate the consistency, safety, and efficacy of the coating for each batch of product to meet the requirements of regulatory agencies such as the FDA and CE.

Solvent Recovery: For safety and environmental reasons, volatile solvents must be recovered or disposed of.

Summary

Ultrasonic insulin cartridge spraying is a highly specialized and precise medical device manufacturing technology. It utilizes the unparalleled uniformity and controllability of ultrasonic spraying to form an extremely thin, perfect functional coating on the inner wall of the insulin cartridge, ultimately ensuring accurate, safe, and effective insulin delivery**. It is a critical advanced manufacturing process in the field of diabetes treatment.

RPS-SONIC Ultrasonic spraying equipment videos: