Ultrasonic Balloon Spraying Technology

Ultrasonic balloon spraying technology. This is a highly specialized and cutting-edge application, primarily focused on high-end medical device manufacturing.

I. Core Concept: What is ultrasonic balloon spraying technology?

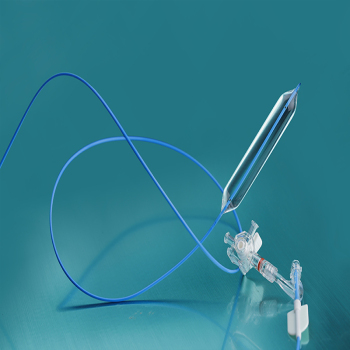

It uses ultrasonic energy to atomize drugs or coating solutions into extremely fine, uniform particles, which are then precisely sprayed onto the surface of a balloon catheter.

Simply put:

Ultrasonic atomization: A core component (the ultrasonic nozzle) generates high-frequency vibrations, breaking the liquid into uniform, micron-sized droplets.

Precision spraying: These droplets are guided by a gentle airflow (laminar flow) and evenly coat the surface of a slowly rotating or moving balloon.

Drying and forming: The solvent evaporates rapidly, leaving a thin, uniform, and precisely dosed drug coating on the balloon.

This technology is primarily used to manufacture drug-coated balloons.

II. Why is this technology needed? What problem does it solve?

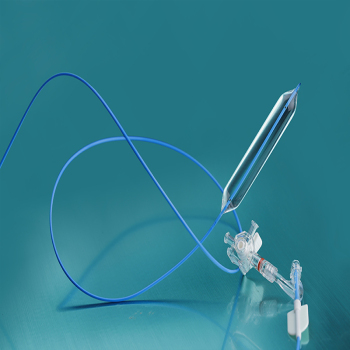

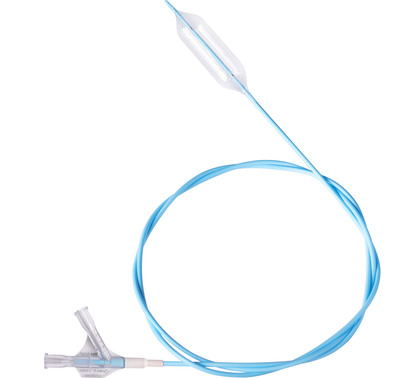

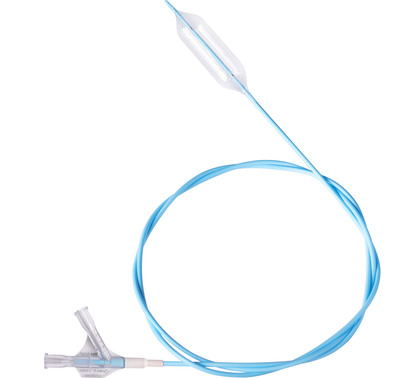

Drug-coated balloons (DCBs) are a major innovation in cardiovascular intervention. They are used to treat vascular stenosis (such as coronary artery or peripheral artery stenosis). The doctor delivers an uninflated balloon to the blockage, inflates it to expand the vessel, and simultaneously rapidly releases the drug (typically an antiproliferative drug such as paclitaxel) onto the vessel wall, inhibiting excessive scar tissue growth and preventing further blockage.

The core requirements for coatings are extremely demanding:

Ultra-high uniformity: The coating thickness must be highly consistent to ensure accurate drug dosing and avoid localized over- or underdosing.

Extremely thin coating: The balloon requires an extremely low outer diameter to reach the lesion, requiring an extremely thin coating (typically micrometers).

Coating durability: The coating must not fall off during delivery (otherwise causing embolism), yet must be quickly and evenly transferred to the vessel wall during balloon inflation.

Drug stability: The process must not destroy the drug's chemical structure and efficacy.

Traditional spraying methods (such as pressure spray guns) struggle to meet these requirements, but ultrasonic spraying technology perfectly addresses these challenges.

III. Technical Principles and System Composition

Ultrasonic Atomization Principle:

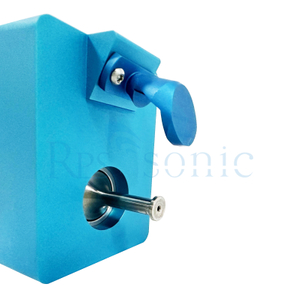

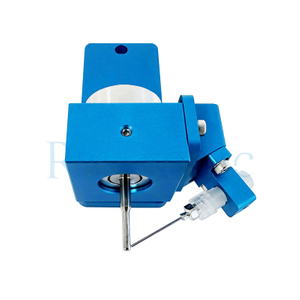

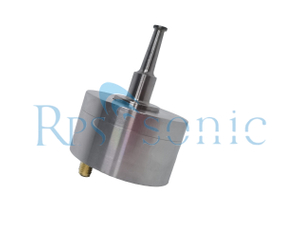

The core of the system is a piezoelectric ceramic transducer, which converts high-frequency electrical signals (e.g., 20kHz, 40kHz, 60kHz, or higher) into mechanical vibrations of the same frequency.

These vibrations are transmitted to the atomizing plate at the end of the nozzle, generating high-frequency "standing waves" on the plate surface.

When the coating liquid is delivered to the surface of the atomizing plate, it is "torn apart" by these high-frequency vibrations, overcoming the liquid's surface tension and forming droplets of a single diameter and extremely small size (typically 5-20µm). This is fundamentally different from the varying droplet sizes produced by traditional pressure spray guns.

Key System Components:

Ultrasonic nozzle: The core atomizing component.

Liquid Supply System: A precision pump that delivers the liquid at a stable, controllable flow rate.

Atomizing/Curtain Gas System: A mild inert gas (e.g., nitrogen) is used to "blow" the atomized particles toward the balloon, creating an air curtain to prevent the droplets from spreading and ensure a precise spraying area. Precision Motion System: Typically a multi-axis system controls the relative motion between the spray head and the balloon. The balloon itself also slowly rotates to ensure uniform 360° coverage.

Drying System: Gentle heating or airflow typically evaporates the solvent during or after spraying, securing the coating.

The following diagram visually illustrates the core workflow of the ultrasonic balloon spray system:

IV. Highlights of the Technical Advantages

Unparalleled Uniformity: Produces droplets of a single diameter, resulting in an extremely uniform coating, which is key to ensuring accurate dosing.

Extremely High Transfer Efficiency: Over 95% of the drug solution is effectively deposited onto the balloon surface, with minimal waste. This is crucial for expensive drugs.

Precise Dosage Control: By controlling drug concentration, delivery rate, and spraying time, the drug dosage per unit area can be precisely controlled.

Gentle Process: The low-temperature, high-pressure atomization process does not compromise the activity of sensitive drugs.

Repeatability and Consistency: The entire process is automated by software, eliminating the instability of manual operation and ensuring high batch-to-batch consistency. Compatible with Complex Formulations: Able to atomize drug solutions of various viscosities and solids contents.

V. Main Application Areas

Cardiovascular Drug-Coated Balloons: This is the most mainstream and demanding application, used in coronary and peripheral arterial applications.

Urology/Gastrointestinal Balloons: Examples include drug-coated balloons for treating benign prostatic hyperplasia or esophageal stenosis.

Coated Balloons: A polymer film is sprayed onto the balloon to carry drugs or achieve special functions.

Other Precision Medical Device Coatings: Examples include functional coatings (antimicrobial and anticoagulant coatings) for components such as stents and catheters.

VI. Challenges and Considerations

System Complexity: The device is highly integrated, involving precision mechanics, fluid control, and automation software, resulting in high initial investment and maintenance costs.

Process Development Difficulty: Extensive parameter optimization (such as frequency, flow rate, air pressure, and motion speed) is required for specific drug-solvent formulations to achieve optimal results.

Sterility and Environmental Control: The production process is typically conducted in a cleanroom and must meet the strict regulatory requirements for medical device production (such as GMP).

Summary

Ultrasonic balloon spraying technology seamlessly integrates cutting-edge ultrasonic technology with the demands of high-end medical device manufacturing. Rather than traditional "welding" or "cutting," it serves as an extremely precise micron-level metering and coating tool, becoming an indispensable core process for manufacturing next-generation drug-coated balloons and directly driving the development of minimally invasive interventional therapies.

RPS-SONIC Ultrasonic spraying equipment videos:

English

English