Knowledge of ultrasonic spot welding machine

Summary of ultrasonic spot welding machine

The ultrasonic spot welding machine is divided into: ultrasonic spot welding machine, ultrasonic plastic spot welding machine, rivet spot welding machine, ultrasonic metal welding machine, ultrasonic metal spot welding machine, ultrasonic welding machine, etc.

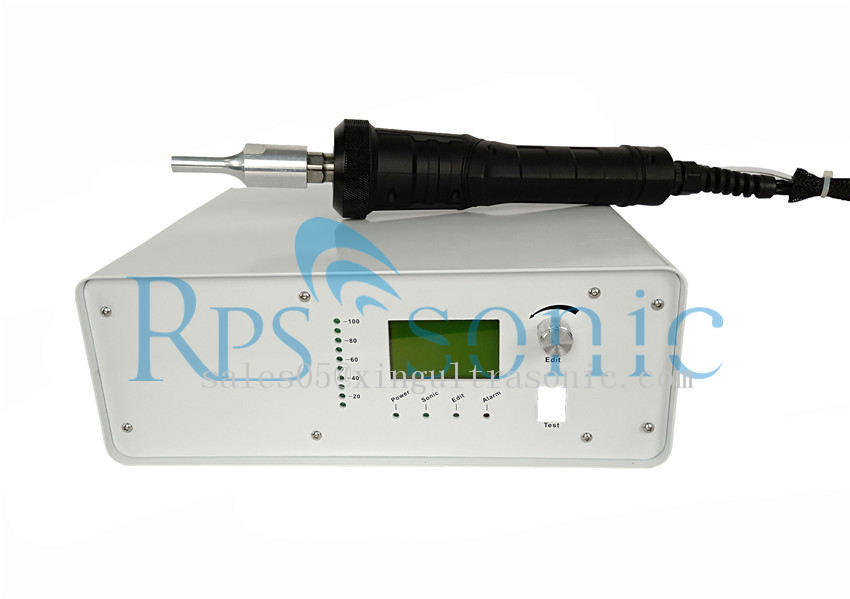

Component of ultrasonic spot welding machine

The components of ultrasonic electric welding machine can be divided into:Generator, pneumatic part, program control part and transducer etc.

The main work of the generator is to convert power supply with 50HZ power frequency into high frequency (20KHZ) high voltage wave through electronic circuit.

The main work of the pneumatic part is to complete the task of pressurizing and holding pressure in the process of processing.

The program control part guarantees the control of the whole machine's work flow, and then achieves the synchronous processing effect.

The task of the transducer part is to further convert the high-voltage wave generated by the generator into mechanical vibration, and then through transmission, amplification to achieve the machined surface.

Principle of ultrasonic spot welding machine

The welding principle of ultrasonic metal welding machine is that 50/60 Hz current is converted into 15,20 kHz power by ultrasonic generator. Then the converted high-frequency electric energy will be converted to the same frequency mechanical movement again through the transducer, then the mechanical movement will be transmitted to the weld head of the ultrasonic welding machine through a set of amplitude modulator equipment which can change its amplitude.

Then, the welding head receives vibration, which transfers energy to the joint of the workpiece waiting to be welded. In this area, the vibration energy will be further converted into heat energy by friction vibration, etc., and the plastic will be melted down. When the vibration stops, the transient pressure maintained on the workpiece will cause the two weldments to merge in a molecular link.

Machine characteristics of ultrasonic spot welding machine

1. High-quality imported ultrasonic transducer with strong power and good stability

2. The whole machine is exquisitely designed and small in size.

3. 500W is more powerful and powerful than other ordinary products.

4. Quality imported assembly of main parts and components.

5. The noise is slight and the working environment is environmentally friendly.

Working characteristics of ultrasonic spot welding machine

Fast - 0.01-9.99 seconds per welding

Strength - Sufficient tension to withstand, greater than 20KG

Quality - exquisite welding effect

Economy - no glue, saving material and labor, and reducing costs.

Usage of ultrasonic spot welding machine

1. Connect one end of the cable to the output control cable connector on the vibration cylinder, and the other end to the output control cable socket on the back of the box, and tighten.

2. Wipe the connecting surface of the welded joint clean, connect it to the transducer of the vibration cylinder, and lock it with a wrench. Note: When connecting, it is necessary to ensure that the two joints between the welding head and the transducer coincide and lock. The connection screw should not be too long or the sliding teeth can not be locked. Otherwise, the transmission of sound wave is not smooth, which will cause damage to the machine.

3. When loading and unloading the welding head, two wrenches must be used to lock the welding and transducer separately. Not only one part of the welding head should be locked or unloaded, so as not to cause damage to the portable vibration cylinder.

4. After checking the installation of points 1 and 2, insert the power cord socket into the external power socket and pull the power switch, then the power indicator lights up.

5. Soft pressure sound wave control switch, when the sound wave is transmitted to the welding head, the "squeak" sound of the welding head can be heard, which indicates that the machine works normally and can be put into use.

6. In case of abnormal operation, do not dismantle the equipment privately. Please notify the supplier or send the equipment to the manufacturer for inspection and repair.

Ultrasonic Spot Welding Machine Application Range

1. Plastic toys, water guns, aquarium games, children's dolls, plastic gifts, etc.

2. Electronic products: recording, tape cassette and core wheel, disk case, cell phone battery board and rectifier transformer, switch socket, remote control, electronic mosquito racket, imitation bottle cap, etc.

3. Household appliances: electronic clocks, blow drums, steam ironing water tanks, electric kettles, computers, etc.

4. Stationery daily necessities: stationery box, aquarium ruler, folder seam and shell, pen holder, cosmetic box case, toothpaste tube tail sealing, cosmetic mirror, insulating cup, lighter, condiment bottle and other sealed containers.

5. Automobiles and motorcycles: batteries, headlights, rear lights, meters, reflectors, etc.

6. The application of sports industry: table tennis, table tennis racket, badminton racket, tennis racket, golf club, billiard table, treadmill drum rope skipping grip treadmill, treadmill accessories, jumping box, gymnastic mat, boxing gloves, boxing sandbags, Sanda protector, path signs, X-rack and other sports equipment are widely used in Chao. Sound wave plastic welding machine for plastic spot welding.

7. Ultrasonic washing machine for metal mechanical parts, bearings, pneumatic components, electronic devices, optical devices, medical devices, gold and silver jewelry and parts pretreatment before plating. Power ranges from 100W to 5000W, and special non-standard models such as trough type, submerged type, heating type, high density and low frequency can also be designed and manufactured according to user's needs.

8. The ultrasonic lace breaker, the ultrasonic cotton shaping machine, the ultrasonic lace machine and the ultrasonic mask stiffener in the textile and garment industry are a new production technology in this industry, which can help the industry to improve product grade, increase productivity and reduce work intensity.