1. Introduction

Ultrasonic processing uses ultrasonic vibration tools to drive the abrasive suspension between the workpiece and the tool, impact and polish the processed part of the workpiece, so that the local material is etched into powder. For perforation, cutting, grinding, etc., and a method of joining the workpieces by ultrasonic vibration. Ultrasonic processing technology is one of the special processing technologies, and can often be applied to difficult-to-machine materials that are difficult to complete in traditional processing. Ultrasonic processing technology such as ultrasonic removal processing, ultrasonic surface finishing, ultrasonic welding processing, and ultrasonic processing.

Ultrasound and its characteristics

The propagation of vibration in an elastic medium is called fluctuation, referred to as wave. The physical essence of volatility is the process of energy transfer.

Audible sound waves: sound waves with a frequency between 16 and 160000 Hz.

Infrasound waves: Sound waves with a frequency below 16 Hz.

Ultrasonic: Sound waves with a frequency higher than 16000 Hz.

Ultrasonic waves: Sound waves with a frequency higher than 1010 Hz.

2, the basic characteristics of ultrasound

(1) Ultrasonic waves, like sound waves, have different propagation speeds when propagating in different elastic media such as gases, liquids, and solids.

(2) Ultrasonic energy transfers a very strong energy, which exerts pressure (sound pressure) on obstacles in its propagation direction. Ultrasonic waves are longitudinal waves whose vibration energy can be measured by energy density, and its energy density can reach more than 100W/cm2.

(3) When the ultrasonic wave propagates in the liquid medium, it can generate strong impact and cavitation at the interface, and strengthen the processing.

(4) Ultrasonic waves will produce reflection, interference and resonance phenomena, and the superposition of waves will occur, thereby obtaining greater processing energy.

three. Principles and characteristics of ultrasonic machining

1. The basic principle of ultrasonic machining

Ultrasonic machining uses ultrasonic waves as the power to push the abrasive to impact the surface of the workpiece at a very high speed. The workpiece material is destroyed and falls off under the impact of the abrasive.

A. The ultrasonic generator converts the alternating current into an ultrasonic electric oscillation;

B. The transducer converts electrical oscillations into mechanical vibrations;

C. The horn is amplifying the amplitude to 0.05-0.1 mm, and the driving tool is ultrasonically vibrated.

D. The tool pushes the abrasive to impact at high speed, throw the workpiece, crush the workpiece surface material and remove it;

E. Hydraulic shock waves and cavitation generated by the working fluid accelerate the crack propagation and destruction of the surface material.

F. Ultrasonic processing is the combined result of mechanical impact, polishing, and cavitation. The impact plays a major role.

2, the characteristics of ultrasonic processing

(1) Suitable for processing various hard and brittle materials, especially non-conductive non-metallic materials such as glass, ceramics, quartz, gemstones, diamonds, and the like.

(2) Tools can be made of softer materials for more complex shapes.

(3) The relative movement of the tool and the workpiece is simple, which makes the machine structure simple.

(4) The cutting force is small, the cutting heat is small, deformation and burn are not caused, and the processing precision and surface quality are also good.

four. Ultrasonic processing equipment

Ultrasonic processing equipment is also called ultrasonic processing equipment. Although ultrasonic processing equipments of different power sizes and different companies are different in structural form, their components are basically the same.

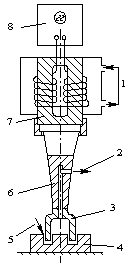

The ultrasonic processing device generally consists of an ultrasonic generator, an ultrasonic vibration system (acoustic component), a machine tool body, and an abrasive working fluid circulation system.

Ultrasonic processing device

1, ultrasonic generator

Function: Transform the power frequency AC into an ultrasonic frequency oscillation with a certain power output.

2. Acoustic components (transducers, horns and booster.)

Function: Converting the high-frequency electric energy output from the ultrasonic generator into mechanical vibration energy, and ultrasonically processing the end face of the tool with high frequency and small amplitude through the horn.

Fives. Ultrasonic technology processing application

A. Although the productivity of ultrasonic machining is lower than that of EDM and electrolytic machining, the machining accuracy and surface quality are superior to them.

B. More importantly, it is possible to process semiconductor and non-metallic hard and brittle materials that are difficult to process, such as glass, ceramic, quartz, silicon, agate, gemstones, diamonds, and the like.

C. For some hardened steels, hard alloy dies, wire drawing dies, plastic molds, etc. after EDM, the ultrasonic polishing and finishing are often used to further reduce the surface roughness.

1, type (cavity) hole processing

Ultrasonic is currently mainly used in the processing of round holes, holes, cavities, nestings, micropores, etc. of brittle and hard materials.

2, cutting processing

Ultrasonic processing of brittle hard materials such as ceramics, quartz, silicon, gemstones, etc., which are difficult to cut by ordinary processing methods, has the advantages of thin section, narrow slit, high precision, high productivity, and good economy.

3, ultrasonic cleaning

Principle: Based on the result of the cavitation effect of the cleaning solution under the action of ultrasonic waves. The strong impact liquid generated by the cavitation effect acts directly on the part to be cleaned, causing the dirt to be destroyed and falling off the surface to be cleaned.

Application: It is mainly used for small and medium precision parts with complex geometry, high cleaning quality and poor cleaning effect by other methods, especially deep small holes, micro holes, curved holes, blind holes, grooves, narrow slits, etc. on the workpiece. Fine cleaning, high productivity and purification rate.

Currently used in the cleaning of semiconductors and integrated circuit components, instrumentation parts, electric vacuum devices, optical components, medical devices, etc.

4, ultrasonic welding

Principle: Ultrasonic vibration is used to remove the oxide film on the surface of the workpiece, so that the workpiece is exposed on the surface of the body, so that the surfaces of the two workpieces are frictionally heated under the impact of high-speed vibration and affinity-bonded together.

Application: It is used to weld nylon, plastic and aluminum products with easy to form oxide film on the surface. It can also be used to hang tin and hang silver on non-metallic surfaces such as ceramics to improve the solderability of these materials. Welding rare metals that are generally difficult to weld. Such as titanium, molybdenum, etc.

5, composite processing

Ultrasonic machining of hard metal materials such as hard alloys and heat-resistant alloys has low processing speed and high tool loss. In order to improve processing speed and reduce tool loss, ultrasonic injection, electrolytic machining or EDM is used to process the injectors. Holes or slits on the spinneret can greatly increase productivity and quality.

6, non-destructive testing

Ultrasonic directional emission, reflection, and penetration of most material properties for non-destructive testing in ranging, control, monitoring, and material measurement.