Yes, ultrasonic technology can be applied to sterilize microorganisms. Ultrasonic technology has a wide range of applications in the field of microbiology, including using ultrasonic waves to kill and sterilize microorganisms.

Ultrasonic waves generate high-frequency vibration waves in liquids, leading to intense physical effects such as cavitation, eddy currents, and resonance effects. These effects can cause the cell membranes of microorganisms to rupture, damage cell structures, and result in cell death.

In practical applications, ultrasonic technology is typically used in conjunction with appropriate disinfectants or sterilizing solutions to enhance sterilization effectiveness. Ultrasonic waves can help disinfectants penetrate microorganism cells more effectively, accelerating cell destruction and death.

Therefore, ultrasonic technology is widely used in microbiology across various fields, including bacterial inactivation in laboratories, disinfection and cleaning of medical instruments, microbial control in the food industry, and more. Through the proper use of ultrasonic technology, efficient sterilization and microbial killing operations can be carried out effectively.

The ultrasonic treatment system has been proven effective in killing bacteria, plankton, and larger organisms. Ultrasonic cavitation in ballast water treatment is a mechanical/physical treatment method that avoids the addition of any expensive active chemical substances to ballast water. This ensures that the environment is not polluted while achieving a high biological effect in destroying and deactivating organisms and microorganisms in ballast water.

Background:

When ships do not have a full cargo load, ballast is needed to maintain their stability and safety. Water is commonly used as ballast, but when collected from its source, a variety of organisms enter the water, typically comprising planktonic communities. These organisms may be introduced to a new ecosystem at the destination, potentially causing unnecessary biological pollution. To prevent this potential contamination, an effective disinfection system must be used to treat ballast water.

The invasive spread of aquatic organisms has been identified by the Global Environment Facility (GEF) as one of the four major threats facing the oceans. This can have extremely serious impacts on the environment, economy, and public health. In order to avoid the introduction of harmful mollusks (such as zebra mussels, Asian clams, etc.), various ballast water sterilization treatments (also known as disinfection or neutralization) can be employed. A common treatment method involves chemically cleaning ballast water, but the chemicals used are harmful to the environment and costly. With the increasing regulations on ballast water management laws, ships are integrating various ballast water treatment methods such as ultrasonic disinfection to comply with regulations.

Ultrasonic Pressurized Water Sterilization

Ultrasonic pressurized water treatment is a mechanical/physical method that avoids the use of harmful and expensive chemicals. Cavitation force can kill small aquatic organisms and microorganisms. Some studies have shown that ultrasonic waves have a high biological effect on zebra mussels, nematodes, bacteria, and viruses.

Ultrasonic Cavitation Disinfection

High-power ultrasonic waves generate cavitation bubbles in liquid, leading to the generation of intense shear forces and high stresses. When intense ultrasonic waves couple into the liquid, the sound waves propagate into the liquid medium, causing alternating cycles of high pressure and low pressure, depending on the frequency. During the low-pressure cycles (rarefaction phase), high-intensity ultrasonic waves create small vacuum bubbles or gaps in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they violently collapse during the high-pressure cycles (compression phase). This phenomenon is known as cavitation. During implosion, localized very high temperatures (around 5,000K) and pressures (around 2,000 atm) are reached. The implosion of cavitation bubbles also results in liquid jet velocities of up to 280m/s.

This high-energy bubble generation and collapse result in hydrodynamic shear forces and ultrasonic oscillations, disrupting the cell walls of organisms effectively killing them. The environmental impact of ultrasonic-assisted techniques currently has no known or anticipated environmental issues.

Biological Effects of Ultrasonic Waves

Some studies have shown that ultrasonic waves can effectively affect viruses and bacteria. Disinfection studies using ultrasonic devices on a flow volume of 100gpm (gallons per minute), equivalent to 23 m3/h, showed a reduction of 7 log for poliovirus (<5μm), a reduction of 6-7 log for Cryptosporidium bacteria. A 100% mortality rate was achieved with nematodes (Ascaris) (8-10μm) and mollusks zebra mussels (70μm). In a 600 gpm flow system, the mortality rate of zebra mussels was the same.

The inactivation rate of large organisms reached 100%, while the inactivation rate of bacteria and viruses decreased by 6-7 log. Exposed in an experimental continuous flow system for 20 seconds, the inactivation rate of Cryptosporidium oocysts was 93-98.6%, decreasing at 10 seconds (4 log) in an experimental batch reactor. Inactivation rates were also reported for Cryptosporidium (7 log), viable worm eggs (4.2 log), poliovirus (8 log), Salmonella (9 log), and E. coli (9 log).

A 2 log reduction means 99% of the organisms originally present in the water have been inactivated. A 3 log reduction means 99.9% have been inactivated, and so forth.

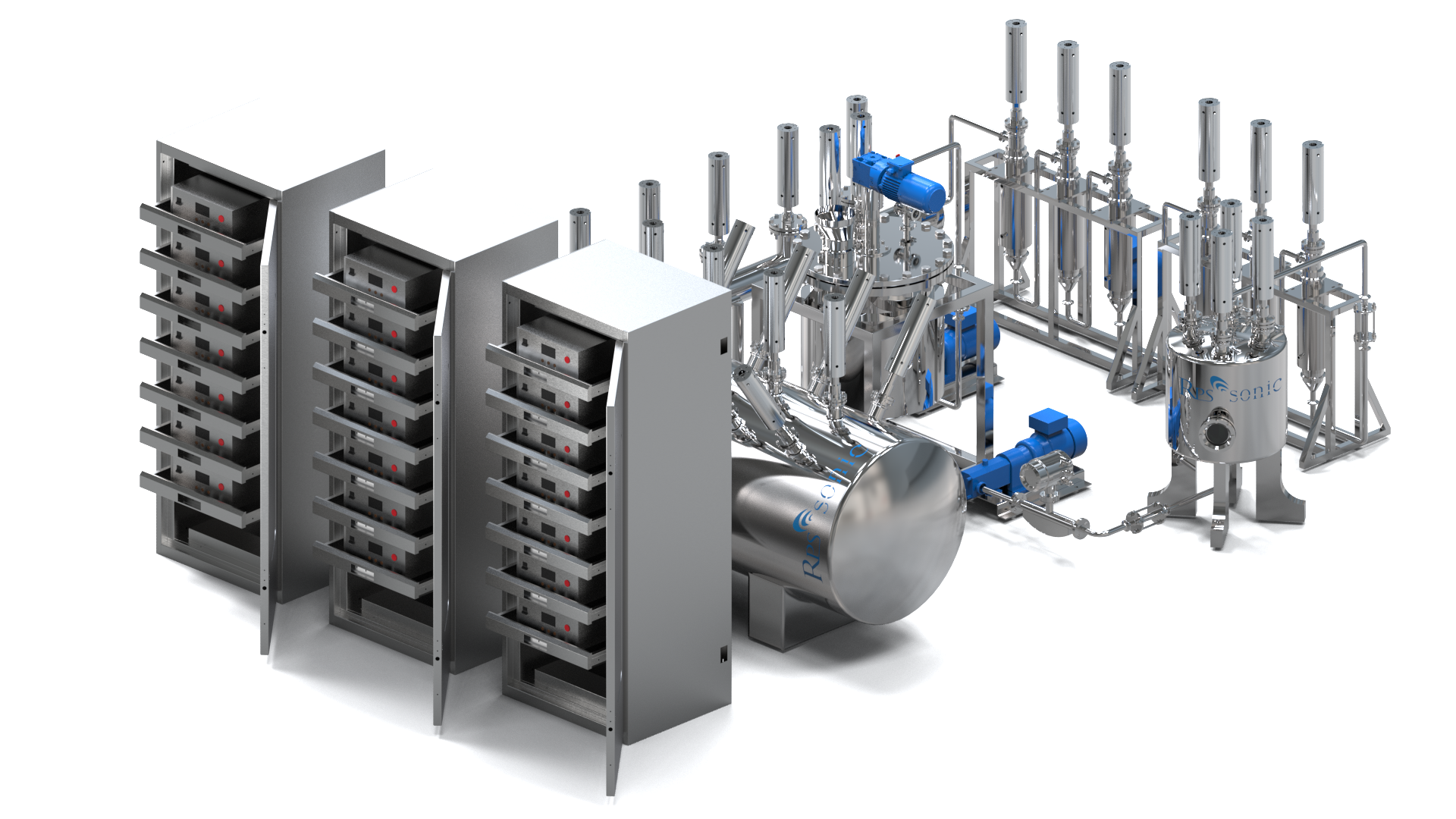

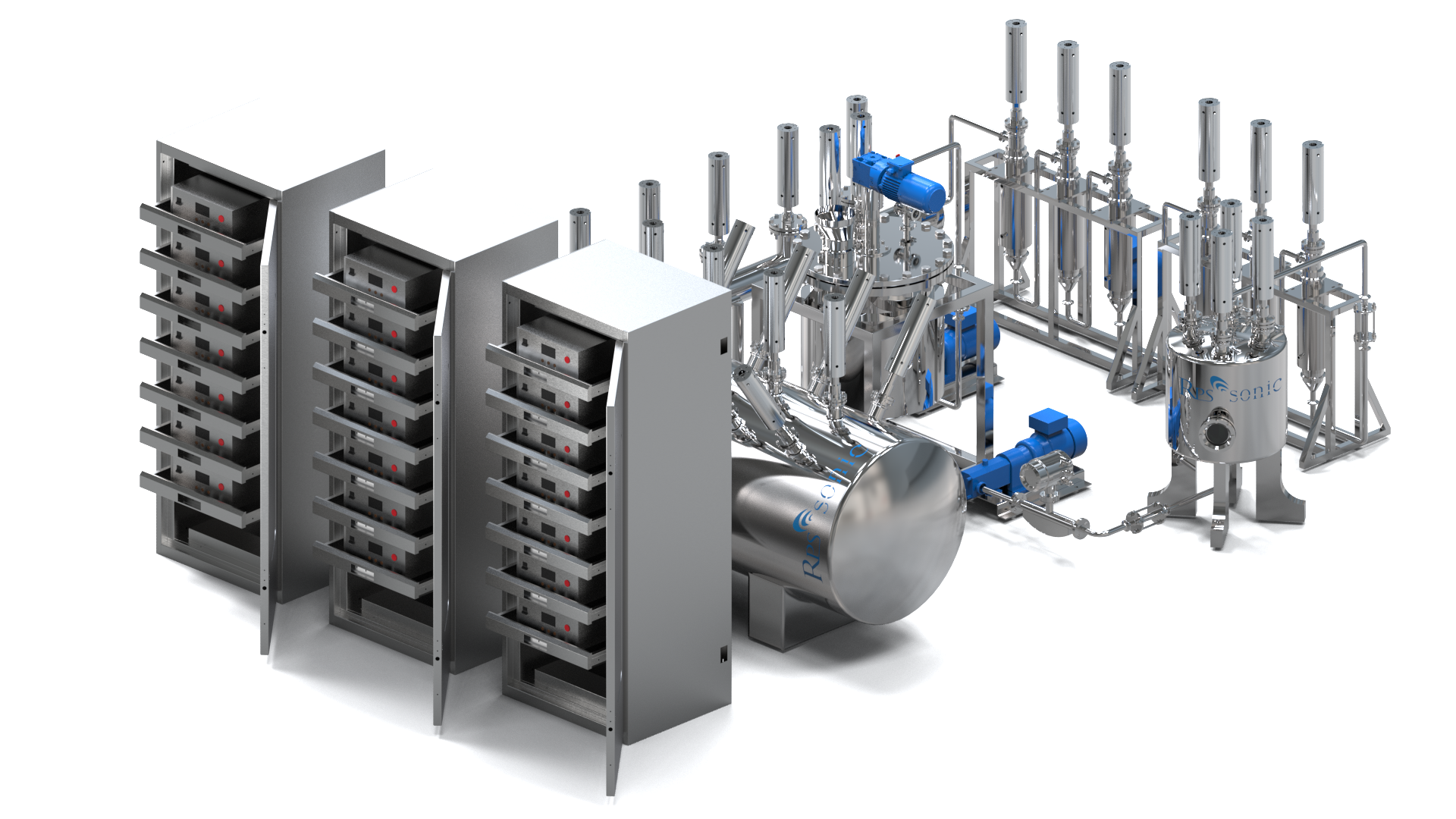

The processing capacity of ultrasonic systems also depends on the output power. High-power/high-intensity ultrasonic devices require less exposure time for inactivation, allowing for higher flow rates to be processed. This ultrasonic system can be used for pressurization and depressurization.

Benefits of Ultrasonic Pressurized Water Treatment

· Chemical-free

· Environmentally friendly

· Efficient

· Synergistic effects

· Low maintenance

· Safe and easy to operate

· Sturdy and reliable

· Scalable to any size

Research into combined treatment technologies shows that ultrasonics are highly synergistic when used in conjunction with other pressurized water disinfection methods (such as ozone, chlorination, UV irradiation, temperature, or high pressure). Due to easy installation and low space requirements, ultrasonic equipment is well-suited for upgrading and improving existing pressurized water treatment systems.