The traditional sewing machine sews two pieces of fabric together by using a needle to thread them, but during the process, the fabric is pierced and there is no actual bond between the fabrics; they are simply held together by a thin thread. This makes the fabric prone to tearing and the thread easy to break. Thermo-plastic fabrics can be fused together using hot air welding, which eliminates the need for needle and thread, but it is difficult to control the welding temperature and the process is slow.

An ultrasonic seamless suturing system can sew most thermo-plastic fabrics. Compared to conventional needle and thread sewing, ultrasonic suturing offers advantages such as no need for needle and thread, high stitching strength, excellent sealing properties, and fast sewing speed. Additionally, the ultrasonic seamless suturing system completely solves the problem of inconsistency between the motion direction of the ultrasonic welding head and the fabric, and it can largely replace conventional sewing machines.

Instruction

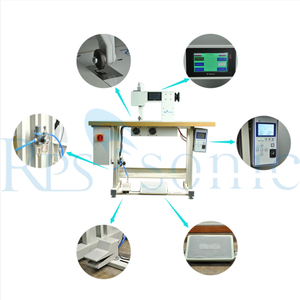

The ultrasonic seamless suturing system consists of a 35kHz ultrasonic transducer, an amplitude converter (providing fixed action), a disc-shaped welding head, and a dedicated CNC power supply. The ultrasonic CNC power supply converts the mains electricity into 35kHz high-frequency high-voltage alternating current and supplies it to the ultrasonic transducer. The ultrasonic transducer converts electrical energy into mechanical energy (ultrasonic waves), generating amplitude when the transducer performs longitudinal expansion and contraction movements, which is then transmitted to the disc-shaped welding head through the amplitude converter. This allows the disc-shaped welding head to perform welding. When combined with a frame, pressure roller, auxiliary structures, and control components, it becomes a complete ultrasonic cutting and sewing machine.

Conventional ultrasonic welding equipment uses longitudinal vibration, and longitudinal vibration welding of fabrics has two major weaknesses:

The equipment is vertically mounted on the sewing panel, resulting in a large and bulky machine.

During cutting and welding, the motion direction of the ultrasonic welding head is not synchronized with the motion direction of the fabric, causing fabric stretching or wrinkling, which seriously affects the cutting and welding accuracy of the fabric.

Conventional ultrasonic longitudinal vibration systems are mainly used for cutting fabrics and are rarely used for fabric sewing. Additionally, traditional ultrasonic welding equipment is mostly used for plastic and metal welding.

The bottom part of an ultrasonic lace machine consists of an ultrasonic vibrating plane, while the upper part features a steel sealing and cutting wheel with patterns engraved on it to enhance the appearance of the welded surface. The fabric passes between the two components, and with the ultrasonic vibrating plane, the upper steel sealing and cutting wheel only applies a small amount of pressure to the fabric, allowing for cutting and welding of thermoplastic materials.

The vibrating part of the ultrasonic sewing machine core is a circular vibrating disc, and the fabric passes between the upper and lower discs, both rotating at a certain speed. This avoids the wrinkling and synchronization issues that can occur during welding due to the continuous rotation of the lace machine.

Equipment Features:

The core technology of the ultrasonic seamless suturing system lies in the use of a disc-shaped welding head for rolling welding, cleverly converting the longitudinal vibration of the transducer into radial vibration that radiates outward 360° along the diameter. Unlike traditional lace machines, which typically consist of a flat tool head and a patterned roller, the static tool head in traditional lace machines can easily cause deformation and wrinkling of fabrics during operation. In contrast, the rolling welding-type seamless sewing equipment uses two vibrating discs to sew fabrics, effectively solving this problem. This significantly reduces the volume of the vibration system, resulting in a smaller installation size, improved aesthetics, reduced weight, and increased overall efficiency.

Advantages:

High Stability: The rotation of the welding wheel and pressure roller in the ultrasonic seamless suturing system is completely synchronized, without any speed or angle differences, ensuring minimal fabric stretching, twisting, or deformation. This results in extremely high accuracy. The thermal fusion effect eliminates the need for needle and thread, increasing product waterproofing, reducing weight, and making folding easier.

Synchronized Welding and Cutting: The ultrasonic seamless suturing equipment is not only suitable for continuous stitching but also capable of cutting textiles during the welding process and achieving automatic edge sealing.

No Heat Radiation: During ultrasonic stitching, the energy penetrates the layers of material for welding, without any heat radiation. In the continuous stitching process, heat is not transferred to the product, which is particularly advantageous for heat-sensitive packaging.

Controllable Seam: The fabric passes through the welding wheel and pressure roller, and ultrasonic waves are used to weld the fabric. By changing the pressure roller, the size and embossing of the seam can be adjusted, providing flexibility and convenience.

Wide Application Range: The ultrasonic seamless suturing equipment can be used to weld all thermoplastic (softened by heat) fabrics, special tapes, and films. The rolling wheel is made of hardened steel, extending its service life.

Applications:

Technical Industry: Filter bags, healthcare products, medical mattresses and pillows, needle-punched blankets, surgical sheets, foils, bulletproof vests, blinds and awnings, pleated filters, shower curtains, partition fabrics, seat covers, MBR modules, and more.

Clothing Industry: Outdoor apparel, protective clothing, bras, lingerie, medical garments and curtains, soft shells, sportswear, cleanroom garments, and more.

Automotive Industry: Interior and insulation projects, protective car covers, sunshades, and more.

Parameter

Frequency 20~36 Khz Power 800W

Sewing speed 0.1-1.3m/s Roller amplitude 18~28μm

Roller temperature Less than 60℃ Roller material Titanium, quenched steel

Work mode Continuous / intermittent Product properties Sewing machine parts

Weld width 0.1~25mm