Formation and Influencing Factors of Ultrasonic Atomization

Liquid atomization is a process in which a liquid film, disturbed by enough surface disturbance in the normal direction, separates from the surface and splits into small droplets, such as mist in the gas phase. Liquid atomization plays an important role in spray drying, coating, spray cooling, incineration and combustion of liquid fuel and waste, preparation of fine powder, preparation of emulsion and other industrial processes. In these applications, most of the droplets are required to have the required size distribution.

Classification of Atomization

Different types of atomization processes are adopted, and the effects of energy transfer on the surface atomization of liquid film can be classified. Mechanical or traditional atomization processes, such as two-fluid atomization, pressure atomization and disc atomization, use mechanical energy to pressurize or increase the kinetic energy of the liquid so that it can decompose in the form of droplets. These processes require more energy and cannot control the final size of droplets and injection speed.

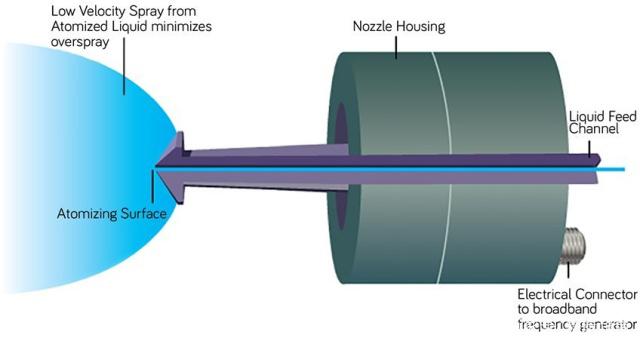

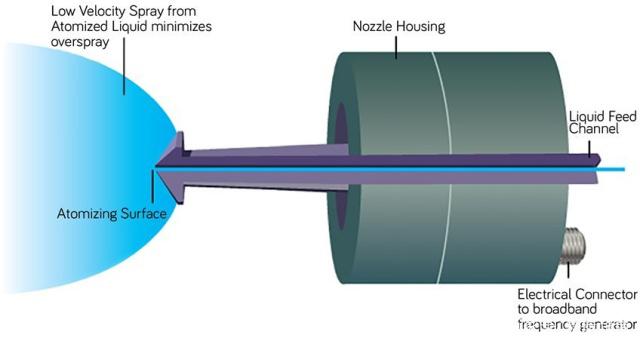

Unlike traditional atomization, ultrasonic atomization can be more efficient. It only needs electric energy to be transmitted to piezoelectric transducer to drive the nozzle to resonate. Droplets have no moving parts, only mechanical vibration generated by the electrical energy provided is used to produce droplets. Because no additional energy is needed, the size distribution of droplets can be better controlled by ultrasonic atomization.

The average diameter of droplets produced by capillary peaks at 10-800 kHz of forced vibration frequencies of different working fluids (including water, oil and melted wax) is established, and the relationship between the average diameter of spray droplets is established. dp = 0.34*8π / ρf2

Solution | Temperature 25 °C |

| Surface Tension (N/m) | Density (kg/m³) | Viscosity (N s/m²) |

Water | 0.0728 | 997 | 0.00089 |

20% Glycerol | 0.071 | 1045.25 | 0.0015 |

40% Glycerol | 0.07 | 1097.1 | 0.0035 |

60% Glycerol | 0.069 | 1151 | 0.0088 |

20% Methanol | 0.047 | 965 | 0.0013 |

40% Methanol | 0.036 | 932 | 0.0015 |

60% Methanol | 0.029 | 912 | 0.0014 |

0.1% CMC | 0.063 | 1001 | 0.017 |

0.5% CMC | 0.061 | 1005 | 0.062 |

Capillary wave and cavitation effect

The generation of ultrasonic atomization is based on capillary wave effect and cavitation effect. When a low power is applied to a 20KHz ultrasonic atomizer, a regular grid structure is observed on the surface of the atomizer, which has the same number of peaks and troughs per unit area, called capillary wave. This low power input produces surface interference without actual droplet injection.

Cavitation is a micro-level phenomenon, which can not be observed directly on the surface of the atomizing head with the naked eye. There are two different types of droplets, i. e. near-spherical droplets and stripes, which have higher velocity, and near-spherical droplets have less velocity. Cavitation can be determined.

The formation of cavities near the atomizer surface and in the liquid film and the subsequent collapse of these cavities result in the local release of a large amount of energy; therefore, compared with the low spray velocity observed in the case of capillary wave propagation, the cavitation effect greatly increases the spray velocity of droplets. At the same time, the surface area occupied by the liquid at the tip of the atomizer decreases with the increase of the frequency of the atomizer, which makes it difficult to capture capillary waves on the surface.

Effect of Dynamic Frequency on Droplet Size

液滴尺寸随着照射频率的增加而降低。随着频率的增加波长的减少导致阻尼节点和波腹点的压缩。雾化液体在循环中暴露于更多的压缩相,导致峰值增长率降低,相应的液滴尺寸减小。随着频率的增加,可用于形成液滴的雾化表面积减小。覆盖整个表面所需的阈值液体流速随着频率的增加而增加。

The droplet size decreases with the increase of irradiation frequency. With the increase of frequency, the decrease of wavelength leads to the compression of damping nodes and wave nodes. The atomized liquid is exposed to more compressed phases in the circulation, which results in the decrease of peak growth rate and the corresponding droplet size. With the increase of frequency, the atomization surface area which can be used to form droplets decreases. The threshold liquid velocity required to cover the whole surface increases with the increase of frequency.

The upper flow limit of high frequency atomizer before dropping is less than that of low frequency atomizer. The wavelength of capillary wave decreases with the increase of atomizer frequency. The final result is that the droplet size decreases and the droplet ejection rate (the number of droplets per unit time) increases from the surface.

Effect of Flow Rate on Droplet Size

Droplet size (dp) increases with the increase of flow rate (Q), which can be attributed to the increase of the thickness of liquid film formed on the vibrating surface before actual atomization. When the liquid flow rate is slightly higher than the critical flow rate needed to wet the tip surface of the nozzle completely, the liquid diffuses as a thin liquid film and has multiple capillary waves composed of peaks and troughs.

When the liquid velocity is obviously higher and the ultrasonic vibration condition remains unchanged, a thicker liquid layer is formed on the surface of the atomizer, which leads to the deformation of uniform capillary wave. This irregular capillary wave leads to the formation of droplets with higher droplet size and larger size distribution. Moreover, with the increase of the thickness of the layer on the surface of the atomizer, oscillating cavitation bubbles or bubbles are observed very close to the surface of the atomizer, which grow rapidly and collapse to spray droplets from the peak prematurely, resulting in cavitation effect. Any further increase in the flow rate will result in droplets falling and the droplet size distribution becomes wider.

Critical flow rate: The flow rate required for complete wetting of the nozzle tip surface. Calculating formula: Qcrit = σ / fρ

Effect of Power on Droplet Size

The droplet size increases with the increase of ultrasonic power. Large droplet size was observed at higher flow rate and higher liquid power consumption. With the increase of ultrasonic power, the vibration amplitude at the tip of the atomizer increases, resulting in the change of the shape of the atomizing flow from radial to conical. When the liquid diffuses to the whole surface of the atomizer with low power ultrasound, the liquid can utilize all the power transferred to the tip, resulting in the drop size reduction. With the increase of power, the operation intensity increases, because the liquid coverage area of the nozzle tip decreases.

The velocity of droplets increases with the increase of ultrasonic power, which can also be attributed to the increase of vibration amplitude at the tip of the atomizer and the increase of cavitation effect in the release of acoustic energy. When the spraying motion is vertical, gravity also affects the kinetic energy of droplets larger than 150 um. For applications such as surface coatings, it is not desirable to operate under high power conditions, because droplets bounce back after hitting the surface and may form irregular shapes on the surface, resulting in uneven coating.

Explain the direct dependence of vibration tip amplitude on power dissipation: Power = ρCSU2 / 2 I =ρCSU2 / 2

Acoustic velocity is defined as (U) (Am × ω0) = (Am × 2πf)

I = ρC(Am*2πf)2 /2

Effect of Liquid Viscosity on Droplet Size

The droplet size decreases slightly with the increase of liquid viscosity. As the liquid viscosity increases, the atomizer needs more energy to decompose the liquid layer into droplets. Initially, without immediate disintegration, the liquid layer remained on the surface of the atomizer for a period of time before splitting into droplets. Therefore, there is no atomization at the initial stage, and the liquid oscillates on the surface of the atomizer because the amplitude dissipates viscous energy and increases temperature, which is not observed in the lower viscous liquid. After a period of time, due to the dissipation of mechanical energy caused by cavitation events, the temperature of the liquid layer on the surface rises, and then the liquid atomization is observed. Compared with low-viscosity liquids (at the same liquid flow rate), high-viscosity liquids require more energy for atomization.

Effect of Liquid Tension on Droplet Size

With the decrease of liquid tension, the atomized particles also decrease. The decrease of surface tension results in the decrease of surface capillary wavelength. The number of capillary waves per unit vibration region increases, and the amplitude of capillary waves is larger. The droplets are immediately ejected from the peak. Therefore, at the same liquid velocity, the number of droplets sprayed increases with the droplet size decreasing.

The ultrasonic power and the surface energy of the liquid film are conserved with the kinetic energy and surface energy of the droplet. Therefore, the increase of the kinetic energy of the droplet is related to the decrease of the size of the droplet. In addition, because the liquid film occupies a very thin layer on the vibrating surface and almost adheres to the surface of the atomizer, the decrease of surface tension is likely to increase the growth of vapor cavitation bubbles. This results in the bubble breakdown in the thin liquid film on the surface of the atomizer, resulting in smaller droplets, but spraying at a higher speed.

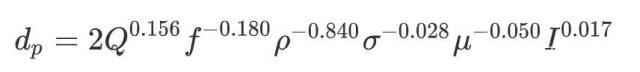

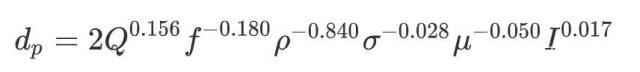

According to the variation of droplet size with operation parameters (including equipment parameters, physical and chemical properties and flow rate of droplets), the correlation formula for predicting droplet size was established. As an initial approximation, the simplest method is based on fitting correlation, assuming that the power law changes of independent variables According to the variation of droplet size with operation parameters (including equipment parameters, physical and chemical properties and flow rate of droplets), the correlation formula for predicting droplet size was established. As an initial approximation, the simplest method is based on fitting correlation, assuming that the power law changes of independent variables (Q,μ,σ,ρ,f,I)and the best fitting correlation obtained are as follows:

(Variable range Q= 0.5 to 5 × 107 m3/s, f = 20–130 kHz, ρ = 912–1151 kg/m3, σ = 0.029–0.073 N/m, μ = 0.00089–0.088 N s/m2, I = 15907–913752.9 W/m2)。

Common Variables of Atomization

Am | Tip amplitude (m) | t | Liquid film thickness (m) |

C | Sound velocity in liquid medium (m/s) | U | Speed of sound wave (m/s) |

dp | Droplet diameter (m) | μ | Liquid viscosity (N s/m²) |

f | Excitation frequency (1/s) | λ | Wavelength (m) |

I | Ultrasound intensity (W/m²) | ρ | Liquid density (kg/m³) |

Q | Volume flow rate (m³/s) | σ | Surface tension (N/m) |

Qcrit | Critical Volume Flow (m³/s) | S | Surface area of atomizer (m²) |

English

English