The application of ultrasound in aluminum melt treatment mainly focuses on grain refinement, degassing, homogenization of composition, and improvement of casting performance. The following are the specific applications and related contents of ultrasound in aluminum melt treatment:

1. Principle of ultrasonic aluminum melt/ultrasonic metal melt

Cavitation effect: Ultrasonic waves generate high-frequency vibrations in aluminum melt, forming tiny bubbles that quickly collapse, generating local high temperature and high pressure, and promoting melt flow and homogenization.

Acoustic streaming effect: Ultrasonic waves trigger melt flow, enhance heat and mass transfer, and reduce segregation and inclusions.

Grain refinement: Ultrasonic vibration promotes nucleation, inhibits grain growth, and thus refines grains.

2. Main applications of ultrasonic aluminum melt/ultrasonic metal melt

(1) Grain refinement

Ultrasonic vibration can significantly refine the grains of aluminum melt and improve the mechanical properties of the material (such as strength and toughness).

Grain refinement can also improve the processing performance of aluminum materials and reduce cracks and defects.

(2) Degassing

Aluminum melt easily absorbs hydrogen and forms pore defects. The cavitation effect of ultrasound can effectively remove gas from the melt and reduce pores in the casting.

The degassing effect is better than the traditional inert gas purging method.

(3) Homogenization of composition

Ultrasonic stirring makes the distribution of alloying elements in the aluminum melt more uniform and reduces segregation.

For aluminum alloys (such as Al-Si, Al-Mg, etc.), ultrasonic treatment can improve the distribution of eutectic phase.

(4) Improve casting performance

Ultrasonic treatment can improve the fluidity of aluminum melt and reduce defects such as shrinkage cavities and shrinkage during casting.

For thin-walled castings or castings with complex shapes, ultrasonic treatment is particularly effective.

(5) Enhance the performance of composite materials

In the preparation of aluminum-based composite materials (such as Al-SiC, Al-Al₂O₃), ultrasonic treatment can improve the dispersion of reinforcing phases (such as silicon carbide and aluminum oxide) and enhance interface bonding.

3. Advantages of ultrasonic aluminum melt/ultrasonic metal melt

High efficiency and energy saving: short processing time and low energy consumption.

Non-contact treatment: avoid the introduction of foreign impurities and reduce pollution.

Wide applicability: suitable for pure aluminum and various aluminum alloys.

Environmental protection: no chemical refiner or degasser is required to reduce environmental pollution.

4. Challenges of ultrasonic treatment of aluminum melt/ultrasonic metal melt

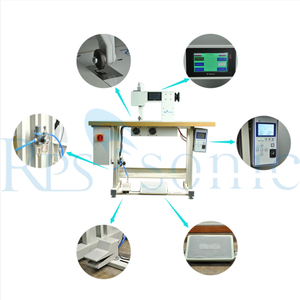

High equipment requirements: high temperature and corrosion resistant ultrasonic equipment is required, and the temperature of aluminum melt is usually above 660°C.

Parameter optimization: parameters such as ultrasonic frequency, power, and processing time need to be optimized according to the specific alloy composition and melt volume.

Limitations of large-scale application: In large-scale production, how to uniformly apply ultrasonic waves is still a technical problem.

5. Research progress of ultrasonic metal melt

Development of new aluminum alloys: Ultrasonic treatment is used to develop high-performance aluminum alloys, such as high-strength aluminum alloys, heat-resistant aluminum alloys, etc.

Composite material preparation: Ultrasonic waves assist in dispersing reinforcing phases to improve the performance of aluminum-based composite materials.

Numerical simulation: Optimize ultrasonic treatment parameters through numerical simulation to improve the treatment effect.

6. Future Outlook of ultrasonic metal melt

Equipment Improvement: Develop more efficient and durable ultrasonic equipment to meet the needs of large-scale production.

Process Optimization: Combine other technologies (such as electromagnetic stirring and mechanical vibration) to further improve the processing effect.

Application Expansion: Explore the application of ultrasound in the treatment of recycled aluminum melts to improve the quality of recycled aluminum.

7. Practical Application Cases of ultrasonic metal melt

Aluminum Alloy Casting: In the casting of automotive parts and aerospace parts, ultrasonic treatment is used to improve the quality of castings.

Aluminum-based composites: In electronic packaging materials and lightweight structural materials, ultrasonic treatment improves the performance of composites.

Recycled aluminum treatment: Ultrasonic treatment is used to remove impurities and gases in recycled aluminum and improve the utilization rate of recycled aluminum.

Conclusion

The application of ultrasonic metal melt has significant advantages, which can effectively refine grains, degas, homogenize components and improve casting performance. Despite the challenges of equipment requirements and large-scale applications, with the advancement of technology, the application prospects of ultrasonic treatment in the aluminum industry are broad, especially in the field of high-performance aluminum alloys and composite materials.