Application of strong ultrasonic in chemical area

Also known as "active application of high power ultrasonic", it is a technique that utilizes strong ultrasonic to act on matter to alter or accelerate the change of some physical, chemical, and biological properties or state of matter. The application of strong ultrasonic in chemical industry has made new developments in recent years, showing a broad prospect. This paper intends to review the application of strong ultrasonic in the chemical industry, with a view to attracting attention in the chemical field for strong ultrasonic applications.

One. Overview of strong ultrasonic mechanism

When a certain intensity of ultrasonic waves propagates through the medium, it will produce a series of effects such as mechanics, heat, optics, electricity and chemistry. These effects are summarized and have three basic functions.

1. Mechanical action. Ultrasonic waves are a form of mechanical energy propagation that is related to passive processes and produces linear alternating vibrations. This mechanical energy is mainly reflected in the vibration, acceleration shock, and sound pressure shear equivalent stress between the mass points of the medium. If 28khz, the sound intensity of 1W/cm2 propagates in the water, the sound pressure value produced is 242kpa, which means that 28,000 vibrations are generated under the pressure of 242kpa, and the maximum mass acceleration is about 2000 times the acceleration of gravity. .

2. Cavitation. When a certain intensity of ultrasonic waves propagates in the liquid medium, the oscillation, enlargement, contraction, and collapse of the microbubbles in the liquid cause a strong shock wave in the liquid near the bubble, forming an extreme high temperature and high pressure of the local point, and cavitation bubbles. At the moment of collapse, a high temperature of 5000k or more and a high pressure of about 50mpa are generated in a small space around it. The temperature change rate is 109k/s, and it is accompanied by a strong shock wave and a microjet with a speed of 400km per hour. This extreme high voltage, high temperature and high The jet is generated by tens of thousands of continuous actions per second. Ultrasonic cavitation causes the turbulence effect, the perturbation effect, the interface effect, and the energy gathering effect. The turbulence effect makes the boundary layer thinner and increases the mass transfer rate; the perturbation effect enhances the micropore diffusion; the interface effect increases the mass transfer surface area; the energy-concentration effect expands the separation of matter molecules and strengthens the chemical separation and strengthening as a whole. The mass transfer rate and effect of the process. Therefore, cavitation is the most basic trait of strong ultrasonic.

3. Heat action. Ultrasonic waves propagate through the medium, and their vibrational energy is constantly absorbed by the medium into heat energy, which raises its temperature. Acoustic energy is absorbed to cause local heating in the medium, local heating outside the boundary, and localized heating at the wavefront when the shock is formed.

main application

The earliest application of ultrasonic in biochemistry should be the use of ultrasonic to smash the cell wall to release its contents. Subsequent studies have shown that low-intensity ultrasonic can promote biochemical processes, such as irradiation of liquid nutrients with ultrasonic can increase the growth rate of algae cells, thereby increasing the amount of protein produced by these cells by a factor of three.

The energy density of the ultrasonic sound field is expanded by a trillion times compared with the energy density of the cavitation bubble, causing a huge concentration of energy; the sonochemical phenomenon and sonoluminescence caused by the extreme high temperature and high pressure generated by the cavitation bubble Is a unique form of energy and material exchange in sonochemistry. Therefore, ultrasonic on chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalyst catalytic efficiency, biodegradation treatment, ultrasonic anti-scaling and descaling, biological cell comminution, dispersion And coagulation, and acoustic chemical reactions have an increasing role.

two. Ultrasonic chemistry

1. ultrasonic strengthens the chemical reaction.

ultrasonic enhances chemical reactions. The main driving force comes from ultrasonic cavitation. The collapse of the cavitation nucleus produces local high temperatures, high pressures, and strong shock waves and microjets, providing a new and very special physicochemical environment for chemical reactions that are difficult or impossible to achieve under normal conditions.

2. Ultrasonic catalytic reaction.

As an emerging research field, ultrasonic catalytic reaction has attracted increasing interest from industry players. The main effects of ultrasonic on the catalytic reaction are:

(1) The high temperature and high pressure conditions facilitate the cleavage of the reactants into free radicals and divalent carbon to form a more active reaction species;

(2) The shock wave and the micro jet have a desorption and cleaning action on a solid surface (such as a catalyst), and can remove surface reaction products or intermediates and a catalyst surface passivation layer;

(3) Shock waves may damage the structure of the reactants

(4) a dispersed reaction system;

(5) Ultrasonic cavitation of the metal surface, the shock wave causes the deformation of the metal lattice and the formation of the internal strain zone, and improves the chemical reactivity of the metal;

6) causing the solvent to penetrate deep into the solid, resulting in a so-called inclusion reaction;

(7) Improve the dispersibility of the catalyst.

In the ultrasonic homogeneous catalytic reaction, more research is on the isomerization of olefins using metal carbonyl compounds as catalysts. Suclick et al. studied in detail the reaction of isomerization of 1-pentene to 2-pentene by Fe(co)5 under ultrasonic conditions, and found that the reaction rate under ultrasonic conditions was increased by 105 times compared with no ultrasonic. Suclik et al. believe that the high temperature and high pressure generated by the collapse of ultrasonic cavitation bubbles and the rapid cooling of the surrounding environment are beneficial to the dissociation of Fe(CO)5 and the formation of the higher active species Fe3(C0)12.

Mai, Tsev of the former Soviet Union studied the effect of ultrasonic on heterogeneous catalytic processes earlier and found that ultrasonic can increase the conversion per pass by nearly 10 times, which is believed to increase the dispersion of the catalyst. In recent years, Han et al. investigated the Reformatsky reaction under the action of low-intensity ultrasonic (≤10W/cm2) and found that the reaction yield reached 90% after 30 minutes of ultrasonic. More importantly, it is no longer necessary to prepare a highly active zinc powder by reducing anhydrous zinc chloride, and it is no longer necessary to use trimethyl borate. Suslick et al. studied the reaction at a sound intensity of 50 W/cm 2 and found that the mixture was sonicated at 25 ° C for 5 min, the yield was over 95%, and the cocatalyst was found to be in the yield and reaction time. no effect. Suslick et al. studied in detail the hydrogenation reaction of nickel powder as a catalyst and found that its reactivity increased by 5 orders of magnitude under the action of ultrasonic.

It is well known that ordinary nickel powder has poor catalytic activity for hydrogenation of olefins, and it is generally difficult to carry out the reaction after about 300 hours. However, after the nickel powder was treated by ultrasonication, the reaction started quickly, and the reaction rate first increased with the prolongation of the ultrasonic treatment time, and then gradually decreased. Ronmy and Price studied the auto-oxidation of alkyl nitrobenzene in phase transfer base catalysis. It was found that the reaction rate increased sharply under ultrasonic action, the reaction time was shortened by 2 h, the acid selectivity was significantly improved, and the product contained a large amount of nitro group. Benzoic acid is formed.

ultrasonic also shows unique advantages in the activation, regeneration and preparation of catalysts. The University of Illinois has developed an ultrasonic washing bath that can be used to remove the oxide film on the surface of nickel powder to activate the nickel catalyst. Henry, an Exxon company in the United States, reported that the permanent deactivated nickel-molybdenum catalyst used in hydrocracking can be regenerated by ultrasonic waves. Recently, Suslick et al. studied the interaction of fe(Co)5 and Co(C0)3 under the action of ultrasonic. It was found that a nano-scale Fe-Co alloy catalyst was formed under strong ultrasonic action, which has a dehydrogenation solution for cyclohexane. High activity, detailed mechanism is under further investigation.

3. Ultrasonic polymer chemistry

The application of ultrasonic positive polymer chemistry has attracted widespread attention. Ultrasonic treatment can degrade macromolecules, especially the degradation of high molecular weight polymers is more significant. Cellulose, gelatin, rubber and protein can be well degraded after sonication. At present, the mechanism of ultrasonic degradation is generally considered to be due to the effect of the force and the high pressure of the cavitation bubble burst, and the other part of the degradation may be due to heat. Under certain conditions, power ultrasonic can also initiate polymerization. Strong ultrasonic irradiation can initiate the copolymerization of polyvinyl alcohol and acrylonitrile to prepare block copolymer, and the copolymerization of polyvinyl acetate and polyethylene oxide to form a graft copolymer.

4. Ultrasonic field enhancement of new chemical reaction technology

The combination of new chemical reaction technology and ultrasonic field enhancement is another potential development direction in the field of ultrasonic chemistry. For example, a supercritical fluid is used as a medium, and an enhanced catalytic reaction is performed using an ultrasonic field. For example, a supercritical fluid has a liquid-like density and a gas-like viscosity and a diffusion coefficient, which makes it dissolve as a liquid, and the mass transfer ability is equivalent to a gas. The use of supercritical fluids with good solubility and diffusion properties can improve the deactivation of heterogeneous catalysts. However, if it can be strengthened by ultrasonic field, it is undoubtedly the icing on the cake. The shock wave and micro-jet generated by ultrasonic cavitation can not only greatly enhance the supercritical fluid to dissolve some substances that cause the catalyst to deactivate, but also play the role of desorption and cleaning, keep the catalyst active for a long time, and also have the effect of stirring. The dispersion of the reactant system makes the mass transfer rate of the supercritical fluid chemical reaction to a higher level. In addition, the local high temperature and high pressure formed by ultrasonic cavitation will facilitate the cleavage of the reactants into free radicals, greatly speeding up the reaction rate. At present, there are many researches on supercritical fluid chemical reactions, but there are few studies on using ultrasonic fields to enhance such reactions.

3. ultrasonic enhanced extraction

1, solid-liquid extraction

Solid-liquid extraction is often referred to as extraction in food chemical industry, that is, extracting useful components from materials with a suitable solvent, and heat treatment or mechanical agitation is used to enhance the process. It has been found that the application of power ultrasonic energy can significantly enhance and improve the extraction process. . The perturbation effect of ultrasonic increases the permeability of the solvent into the extract cells and enhances the mass transfer process. Another effect of ultrasonic is that the strong shear force generated by ultrasonic cavitation can break the plant cell wall and make the cells easily released. Containment, this has been confirmed from the study of ultrasonic to increase the sugar extraction rate of sugar beet. Ultrasonic-enhanced solid-liquid extraction is also applied to the extraction of salicylic acid, berberine chlorin, and rock cabbage from Chinese medicine. Alcohol reflux method, which is usually used to extract rock cabbage at room temperature, can obtain more than 50% extraction yield under ultrasonic treatment in half of the extraction time. Effective mass transfer and cell rupture are once again proved to be the main reasons for enhanced extraction. .

The effect of ultrasonic on the extraction of protein from defatted soybeans has been studied. The 20 kHz, 50 W sound field irradiation can improve the continuous extraction process of soybean milk. It surpasses any previous feasibility technology and obtains efficient extraction, and the technology has been expanded. Go to the experimental factory.

The first step in the manufacture of instant tea is to extract the tea solids from the tea leaves, and then remove the water from the pure tea solution by spray drying to obtain the instant tea. ultrasonic at 60 ° C can increase the extraction by 20%. Ultrasonic extraction is more efficient than conventional heat extraction and shortens the extraction time. Most of the material is extracted within the first 10 minutes of the process.

Hypertensive pepsin is an important raw material used in the processing of emulsion into cheese. It can be extracted from the stomach of mammals. The extraction yield is successfully improved by using 19.2 kHz and 3.34 W/cm2 for 45 min. 150g of burdock can only extract 30.60g of pepsin without ultrasonic, and ultrasonic extraction can reach 47.81g, and the activity of protease is slightly improved by ultrasonic extraction compared with the common method.

Examples of the application of ultrasonic enhanced solid-liquid extraction in chemical processes are:

(1) When extracting asphaltenes from oil shale with 8 solvents such as benzene, the extraction rate is 24 times that of Soxhlet's fat extraction method under the action of 50 kHz and 400 W; (2) Sodium hydroxide and chlorination When the ammonium mixed solution is leached from zinc in zinc containing 17.3% zinc ore, the leaching rate can be greatly accelerated by using 22 kHz, 100 W of ultrasonic;

(3) Sound field irradiation at a frequency of 20 khz, power of 100 W and 600 W can increase the rate of pyrethrin in the extraction of powdered pyrethrum from n-hexane;

(4) 24khz, (positive and negative 2.5kHz) 120W ultrasonic irradiation is applied to methanol extraction of benzopyrene (a) in environmental samples, and there is an unparalleled extraction rate by vacuum sublimation;

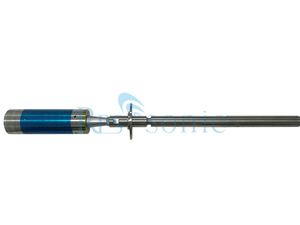

(5) 18.5 kHz, 250 W high-intensity large single-headed insertion ultrasonic field can increase the rate of gold extraction by cyanidation;

(6) 20khz ultrasonic was used to extract the total alkaloids of Motherwort and the extraction was higher than the general reflux method, and the extraction time was shortened. The extraction rate after extraction by reflux method for 2 hours was 0.176%, and the extraction rate after ultrasonic extraction for 40 minutes reached 0.248%.

2, liquid-liquid extraction

Liquid-liquid extraction involves the mass transfer process between two mutually incompatible organic and aqueous phases. The interfacial effect caused by the cavitation of the ultrasonic wave increases the contact area between the two phases, and the turbulence effect caused by the shock wave when the cavitation collapses eliminates the retardation of the two-phase junction, thereby increasing the liquid-liquid extraction rate. For liquid-liquid extraction systems generally controlled by mass transfer rate, the effect of ultrasonic waves is very significant, especially in the liquid-liquid extraction process of metals in the non-ferrous metallurgical industry, when the appropriate ultrasonic frequency and power are applied, the decomposition speed can be greatly enhanced. And increase the extraction rate, with 1MHz, 0.2W / cm2 ultrasonic irradiation for 15min, can be used to separate the phase separation speed of mo and w separated by acidic phosphoric acid extractant by 4-5 times; with 20kHz, 19W/cm2 ultrasonic irradiation The extraction rate of Ga can be increased by 15 times; the extraction rate of Ni can be increased by 4-7 times with ultrasonic irradiation of 20 khz, 47 W, and mechanical stirring.

four. Ultrasonic enhanced crystallization

A large number of experimental studies have shown that strong ultrasonic can both produce a rapid and gentle precipitation of solid solutes in a supersaturated solution and enhance crystal growth. As early as the 1950s, a mixture of procaine solution and penicillin salt was irradiated with l0 kHz ultrasonic to obtain a fine and uniform procaine penicillin crystal precipitate with a particle size distribution of 5 um to 15 um, and the product size obtained by a conventional method. For l0um one 20um. There are two advantages to using ultrasonic in the cooling process of molten metal, that is, degassing and obtaining smaller crystal grains, and under the action of ultrasonic waves, the formed nucleus enters a vibrating state, thereby accelerating the growth process, on carbon steel. Ultrasonic treatment shows that it can reduce the grain size from 200um to 25um to 30um, the ductility of carbon steel by 30% to 40%, and the mechanical strength by 20% to 30%. Studies on the cooling crystallization of metallic zinc show that ultrasonic treatment can increase the critical shear stress intensity by 80%, and the crystal form of metallic zinc changes from cylindrical to uniform under the action of ultrasonic waves with a frequency of 25 kHz and a strength of 50 W/cm2. Hexagon.

Solution crystallization plays an important role in the separation and purification of organic soluble substances and inorganic salts. It can not only separate the solute from the solution in a solid state, but also because the different crystals have different crystal lattices. It can also be used to purify crystalline materials. Qiu Taiqiu and others, under the auspices of the National Natural Science Foundation of China, successfully studied the effects of ultrasonic on the crystallization kinetics of sucrose solution. They influenced the physical properties of supersaturated solution, nucleation and crystal growth. A systematic study was carried out. The results show that under the action of the external sound field, the conductivity of the supersaturated solution increases, the viscosity decreases, the nucleation induction period shortens, and the stability decreases. Thereby, it is advantageous for the sucrose supersaturated solution to precipitate crystals. The energy-concentrating effect of ultrasonic cavitation can provide energy to the supersaturated solution, improve the vibration energy of the whole system, and the interfacial effect reduces the crystallization energy. As a result, the sucrose supersaturated solution can achieve primary nucleation in the stable region. Compared with other stimulation crystallization methods and seeding crystallization methods, the supersaturation required for ultrasonic nucleation is lower, the obtained crystal nucleus is more uniform, complete, smooth, and the crystal nucleus and finished crystal size distribution range is small, and the coefficient of variation Lower. The application of ultrasonic irradiation in the growth of sucrose crystals has both positive and negative effects: on the one hand, the turbulent effect caused by ultrasonic cavitation can reduce the thickness of the boundary layer and increase the mass transfer rate; on the other hand, the ultrasonic cavitation bubble collapses into the The microjet has a eclipse effect on the surface of the crystal, and if the intensity is too large, the crystal will be broken. Therefore, the ultrasonic effect on the crystal growth is related to the crystal size and cavitation bubble size. When the crystal size is smaller than the cavitation bubble radius, the ultrasonic promotes crystal growth; and when the crystal size is larger than the cavitation bubble radius, the ultrasonic damage crystal growth.

Wang Weining et al. introduced the ultrasonic wave with a frequency of 33 kHz and a power of 250 W into the crystallization process of basic magnesium chloride (mg3(OH)5Cl?4H2O), which shortened the induction period of the supersaturated solution, and the crystallization process changed from 12h to 4h, and the ultrasonic frequency was higher. The faster the nucleation rate, the shorter the induction period and the shorter the time required for complete crystallization. Other examples of ultrasonically strengthening solution crystallization such as potassium nitrate, acetamide, and sodium potassium tartrate.

In the food freezing and refrigeration industries, the formation of ice crystals is important for maintaining the original quality of food ingredients. For example, when soft fruits (strawberries) are frozen, as the small granular ice crystals formed in the food cell material continue to grow, when the crystal grain size increases, they will destroy part of the cell walls, that is, destroy part of the structure of the raw materials. It takes a fairly long "expansion time" from the time the water begins to crystallize into ice until the food is completely frozen. Under the action of ultrasonic, more and more uniform ice crystals can be produced, the expansion time is shortened, the final size of the ice crystals is reduced, and the damage to the cells is reduced. ultrasonic studies on the effects of frozen confectionery have shown that the particle size of ice crystals produced by ultrasonic irradiation is significantly reduced and distributed more evenly in solids, which makes frozen confections harder than conventional products, increasing the product's acceptance among consumers. The degree of welcome and the combination of frozen candy and wooden handles.

V. ultrasonic condensation

ultrasonic was used in the early 1940s to enhance the coagulation of suspended solids in aerosols, and in the United States has set off a "spy fever" throughout the country. However, due to the limitations of ultrasonic equipment, this enthusiasm quickly cooled down. Until the emergence of advanced ultrasonic equipment in the 1960s, ultrasonic coagulation began to be applied to the deposition of corrosive gases, the deposition of carbon black and CaCO3, and cement powder. Recovery of tar powder, removal of blast furnace gas, and treatment of flue gas from metallurgical furnaces.

In order to explain the phenomenon of ultrasonic-induced small particle coagulation, that is, the sound field condensation effect, scientists have proposed many hypothetical models. Ultrasonic agglomeration is generally considered to be a process in which when the ultrasonic waves pass through a flowing medium with suspended particles, the suspended particles begin to vibrate with the medium, but since the particles of different sizes begin to vibrate with the medium, the particles of different sizes have different The relative vibration speed, the particles will collide and bond with each other, and the volume and weight increase. Since the particles become larger, they can no longer follow the acoustic vibration, but can only be used for irregular movement and continue to collide and bond. It gets bigger and finally settles down. Kotyasov and Newtson pointed out that the above model can only explain the sound field condensation effect of multi-size suspensions, and it is not convincing to face a single-size suspension system. Based on this, they propose a sound field condensation effect interpretation based on the model of particle collective action. The model considers not only the interaction between two particles, but the overall force between all particles. Under the action of the sound field, in the region where the density of the dispersed particles increases, the effective cross-sectional area of the dispersed phase to the dispersed phase decreases, resulting in an increase in the flow rate of the dispersed phase relative to the particles, accompanied by an increase in the rate of dispersion between the dispersed substances. The pressure is increased, so that the solid particle density is further increased, and as a result, the coagulation process is accelerated. According to this model, a series of relationship between the instability increment of the suspension system and the ultrasonic frequency and ultrasonic power is introduced, and the experimental facts are verified.

Sixth, ultrasonic enhanced filtration and dehydration

The mixture is often filtered during chemical separation to remove solid particles and purify the solution. Conventional filtration methods tend to cause tiny particles to clog the filter and the filter membrane must be replaced frequently. Ultrasonic irradiation has two special effects that help to improve the filtering technique. The sound field condensation effect can cause the aggregation of fine particles to accelerate the filtration rate. The second is that the ultrasonic energy absorption effect provides sufficient vibration energy for the system. Part of the particles are allowed to float in the filtrate, providing a more free passage for washing. Studies have shown that ultrasonic enhanced filtration (ie "acoustic filtration") can quickly reduce the water content of coal slurry containing 50% water to 25%, while conventional filtration can only reach 40%. The "electro-acoustic filtration" combined with the enhanced electric field and sound field can increase the degree of coal slurry drying by 10%. When electroacoustic filtration technology was applied to filter apple juice from pulp, the moisture content of the pulp decreased from the initial 85% to 38%, whereas the conventional method only reduced the water content to 50%.

In the coal rock, minerals and chemical industries, the solid material separated by sedimentation, filtration, etc. must remove the moisture in the material as much as possible before drying, saving energy for the drying step. The sound field has enhanced heat transfer and mass transfer. Swamy et al. studied the removal of water-saturated siderite, sand and sawdust by centrifugal dehydration under high-intensity sound field irradiation of 139dB (about 100W) and 98kHz. The moisture in the material shows that when centrifugal dehydration is applied to the sonic wave, the final water content obtained by centrifugal dehydration without sound wave can be 25% to 95% under different conditions, and the critical temperature is also decreased.

7. Sound field enhanced adsorption and desorption

Adsorption and desorption have been widely used in chemical, food, metallurgical and other industries, playing an increasingly important role in separation and purification. Adsorption and desorption are a pair of reciprocal processes. Under ultrasonic cavitation, the sound field increases the rate at which the adsorbate diffuses toward the adsorbent; on the other hand, it reduces the van der Waals force between the adsorbate and the adsorbent. The former has a positive effect and strengthens the adsorption; the latter has a negative effect and strengthens the desorption. Therefore, selecting appropriate sound field parameters can enhance adsorption and desorption separately.

Ultrasonic enhanced adsorption process is studied: under the action of power ultrasonic, the adsorption rate of polyvinyl alcohol, acetic acid-butyric acid cellulose and glucose is increased in boxboard and decolorized kraft pulp; the adsorption of phosphorus on soil after KH2PO4 treatment is increased. The adsorption amount of methylene blue by clay and activated carbon increased; the adsorption rate of the powdered organic reagent and powdered A1203 to the limited elements increased. However, some studies have found that when phenol formaldehyde ion exchange resin XAD-2 (am berlite XAD-2) adsorbs 4-(2-pyridylazo)isophthalic acid (PAR), the effect of 20 kHz ultrasonic on adsorption rate is lower than 21Orpm. The effect of mechanical agitation, in which the adsorption rate of mechanical agitation is 2-3 times faster than that of ultrasonic.

Early studies on the ultrasonic enhanced desorption process include: desorption of iodine from activated carbon; Ag, Cu, etc. desorption from Ge and Si, Krisccr and Lichtman studied ultrasonic surface wave induced desorption, and observed some adsorbed substances Desorption is attributed to the excitation of the subsurface waves.

In recent years, the desorption regeneration of wastewater adsorbents has been active. It is a simple and quick method to remove organic hydrolytic pollutants such as phenol and phenol substitutes from waste water by using activated carbon and polymer resin, but due to the adsorbent and adsorbate. There is a strong affinity between them, and the desorption regeneration of the adsorbent is still a difficult problem. The most common methods for phenol desorption are thermal desorption and chemical desorption, but the high temperature of thermal desorption leads to a decrease in the exchange capacity of the adsorbent after regeneration, while chemical desorption uses chemicals and requires two separations after desorption. At present, Qin et al. reported the movement of adsorption equilibrium during the desorption of CLTBP resin-phenol system under ultrasonic irradiation. Rege et al. studied the desorption rate of phenol from two polymeric resins when desorbed from activated carbon under the action of 40 kHz, 120 W, 1.44 MHz, 100 W sound field and 40 kHz, 120 W, 40 kHz, 60 W. Variety. Their results show that under ultrasonic irradiation, the ultrasonic diffusion effect increases the diffusion rate of the particles due to the ultrasonic perturbation effect, and the ultrasonic energy absorption effect reduces the activation energy of the first-order surface reaction. Therefore, the ultrasonic energy can promote the phenol from the activated carbon and Desorption on the polymer resin, the rate of desorption is significantly increased, and the effect is more pronounced when the re-energizer is applied at a low temperature, using a regenerant and a high ultrasonic intensity.

Eight. Conclusion

The application of strong ultrasonic often compensates for the shortcomings of conventional chemical reactions and classical chemical separation and purification technologies, and creates a new and effective method to enhance the separation and purification process, which reduces the process time and enhances the process effect. Regardless of industrial applications or academic research, strong ultrasonic will have a broader research prospect in the chemical industry.