what is ultrasonic soldering machine

While "ultrasonic soldering machine" covers the broad technology, "ultrasonic tin soldering" specifies the use of tin-based solders (like tin-silver, tin-copper, or pure tin) as the filler material in the ultrasonic process.

It's the application of ultrasonic energy to achieve flux-free soldering specifically with tin alloys.

Core Concept in a Nutshell

Ultrasonic tin soldering is a process where high-frequency sound vibrations are applied to molten tin solder. This mechanical energy removes oxides and cleans the surfaces, allowing the tin to bond perfectly to the base metal without the need for any chemical flux.

How It Works (The Detailed Process)

Imagine you're trying to solder aluminum with a regular iron and tin solder. It won't work because of the instant oxide layer. Here's how ultrasonic tin soldering solves this:

Melting the Solder: The ultrasonic horn (the tool tip) is heated to a temperature above the melting point of the tin-based solder (e.g., 250-450°C for common tin alloys). The solder is melted, forming a pool on the tip or directly on the joint area.

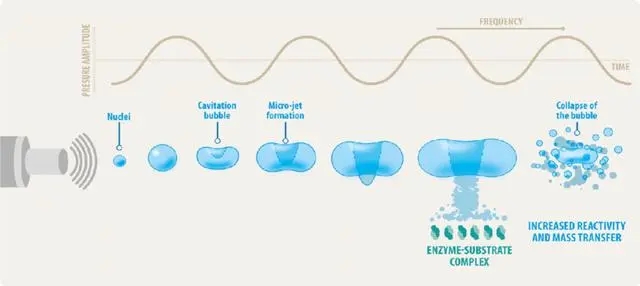

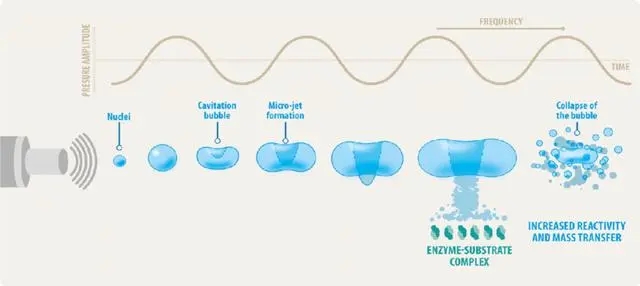

Activating Ultrasonic Vibration: The key step begins. The horn vibrates longitudinally at an ultrasonic frequency (typically 20-40 kHz). This is so fast it's invisible to the human eye—the tip just looks like it's humming.

Cavitation in the Tin Solder: These intense vibrations are transferred into the molten tin solder pool, creating millions of microscopic bubbles that rapidly form and implode. This phenomenon is called acoustic cavitation.

Mechanical Scrubbing Action: The implosion of these cavitation bubbles releases a tremendous amount of energy locally. This acts like a microscopic, ultra-powerful scrubbing brush that:

Blasts away the oxide layer (Al₂O₃ on aluminum, Cr₂O₃ on stainless steel, etc.) from the base metal's surface.

Breaks the oxide skin on the surface of the molten tin solder itself, making it "active" and ready to bond.

Metallurgical Bonding: With both surfaces now perfectly clean and oxide-free, the liquid tin solder can wet and spread over the base metal, forming a strong, intermetallic bond just like in conventional soldering, but achieved through purely mechanical means.

Key Characteristics of the Joint

Flux-Free: The most significant feature. No corrosive residues, no need for cleaning, and no risk of long-term failure from flux contamination.

Bright and Shiny: The resulting solder joint typically has a bright, shiny appearance, unlike the sometimes duller finish of flux-core soldered joints.

Excellent Wettability: The ultrasonic action often results in superior wetting and spread of the tin solder on difficult surfaces.

Primary Applications and Uses

Ultrasonic tin soldering is the go-to method for specific challenging scenarios:

Soldering Aluminum to Aluminum: This is the most common application. It's widely used in the electrical industry (e.g., joining aluminum windings, busbars), HVAC, and refrigeration (e.g., aluminum heat exchangers), and light-weight manufacturing.

Soldering Aluminum to Other Metals: It's excellent for creating a bi-metallic joint, such as Aluminum to Copper, which is crucial in power electronics, motor manufacturing, and heat exchangers.

Stainless Steel and Other Alloys: Joining stainless steel components with tin solder without using aggressive, corrosive fluxes.

Flux-Sensitive Applications:

Electronics: For components where even no-clean flux residue is unacceptable (e.g., high-frequency circuits, sensors).

Medical Devices: Where biocompatibility and absolute cleanliness are paramount.

Food and Aerospace Industries: Where any residue could lead to corrosion or failure.

Coating/Tinning Wires and Surfaces: The process can be used to ultrasonically "tin" the ends of aluminum wires or coat surfaces with a layer of solder for subsequent assembly.

Advantages | Disadvantages |

No Flux Required: Eliminates cost, cleaning, and corrosion issues. | High Equipment Cost: Machines are significantly more expensive than standard irons. |

Works on "Unsolderable" Metals: Enables reliable soldering of Al, SS, etc. | Skill-Intensive: Requires proper technique to avoid damaging parts or insufficient bonding. |

Clean and Eco-Friendly: No harmful flux fumes or waste. | Potential for Erosion: Excessive ultrasonic time can cavitate and erode the base metal. |

Strong, Reliable Bonds: Creates a true metallurgical bond without flux voids. | Not for Standard Electronics: Overkill and impractical for regular PCB soldering with copper traces. |

Summary

Ultrasonic tin soldering is a specialized flux-free process that uses high-frequency sound waves to "scrub" surfaces clean with molten tin solder, allowing it to bond to traditionally difficult-to-solder metals like aluminum and stainless steel. It's a powerful solution for specific industrial, electrical, and high-reliability applications where flux cannot be tolerated.