- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Certification: | |

|---|---|

| Installation: | |

| Pressure: | |

| Frequency: | |

| Power: | |

| Max Capacity: | |

| Tip Head Material: | |

| Availability: | |

| Quantity: | |

SONOL20-1000

RPS-SONIC

8515900090

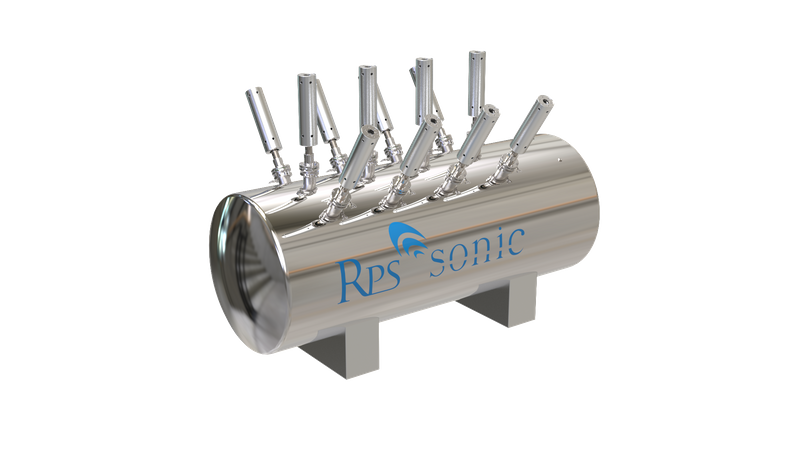

Combined Industrial Ultrasonic Assisted Dispersion Homogenizer for Graphene Dispersion

The cavitation effect of ultrasonic energy Irradiate the solution with a certain sound intensity. When the sound intensity increases to 0.5 ~ 0.7 W / cm *, if you put a hydrophone in the solution, you can hear the strong noise in the solution. . This noise occurs with the phase of the sound field and occurs once in one or more cycles. It has been found that this noise essentially bends when the sound field is in the expanding phase, and the trace gas dissolved in the solution accumulates into small bubbles (also known as cavitation nuclei).

After the sound field becomes a compression phase, the radius meets- Conditioned gas pools are rapidly compressed and inward condensation occurs. In this way, the liquid wall around the bubble produces a strong paddle sound when it shrinks rapidly. This process is usually extremely momentary and only occurs between a few nanoseconds and a few microseconds. For the gas in the bubble, the temperature rises sharply after being compressed.

This temperature is usually astonishingly high, reaching a maximum of more than 10,000 degrees Celsius, and at a few thousand degrees when it is low. This physical process is called cavitation effect, and the accompanying noise is called cavitation noise. This temperature is related to the green strength, the initial radius of the bubble, the radius at which the compression ends, and the specific heat capacity of the gas.

Therefore, as the dissolved gas in the solution is different, the temperature at which the cavitation region terminates after cavitation occurs is not the same, and the volume of the solution in which the rare gas is dissolved often has a higher cavitation termination temperature. The local high temperature in the solution caused by the cavitation effect is the determinant of the chemical reaction.

Parameter

![6RR6T{]1`HPT%8LQ2_KY4[2](http://iirorwxhjionlo5p.ldycdn.com/cloud/njBpqKrrRlkSoiopokjlj/6RR6T-1-HPT-8LQ2_KY4.png)

![C]LLCKM6_7%(R[{`{6_D]7U](http://iirorwxhjionlo5p.ldycdn.com/cloud/npBpqKrrRlkSoioppkjpj/C-LLCKM6_7-R-6_D-7U.png)

Application

• Cell disrupter (extraction of plant substances, disinfecting, enzyme deactivation)

• Therapeutic ultrasound, i.e. induction of thermolysis in tissues (cancer treatment)

• Decrease of reaction time and/or increase of yield

• Use of less forcing conditions e.g. lower reaction temperature

• Possible switching of reaction pathway

• Use of less or avoidance of phase transfer catalysts

• Degassing forces reactions with gaseous products

• Use of crude or technical reagents

• Activation of metals and solids

• Reduction of any induction period

• Enhancement of the reactivity of reagents or catalysts

• Generation of useful reactive species

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous Customers

Combined Industrial Ultrasonic Assisted Dispersion Homogenizer for Graphene Dispersion

The cavitation effect of ultrasonic energy Irradiate the solution with a certain sound intensity. When the sound intensity increases to 0.5 ~ 0.7 W / cm *, if you put a hydrophone in the solution, you can hear the strong noise in the solution. . This noise occurs with the phase of the sound field and occurs once in one or more cycles. It has been found that this noise essentially bends when the sound field is in the expanding phase, and the trace gas dissolved in the solution accumulates into small bubbles (also known as cavitation nuclei).

After the sound field becomes a compression phase, the radius meets- Conditioned gas pools are rapidly compressed and inward condensation occurs. In this way, the liquid wall around the bubble produces a strong paddle sound when it shrinks rapidly. This process is usually extremely momentary and only occurs between a few nanoseconds and a few microseconds. For the gas in the bubble, the temperature rises sharply after being compressed.

This temperature is usually astonishingly high, reaching a maximum of more than 10,000 degrees Celsius, and at a few thousand degrees when it is low. This physical process is called cavitation effect, and the accompanying noise is called cavitation noise. This temperature is related to the green strength, the initial radius of the bubble, the radius at which the compression ends, and the specific heat capacity of the gas.

Therefore, as the dissolved gas in the solution is different, the temperature at which the cavitation region terminates after cavitation occurs is not the same, and the volume of the solution in which the rare gas is dissolved often has a higher cavitation termination temperature. The local high temperature in the solution caused by the cavitation effect is the determinant of the chemical reaction.

Parameter

![6RR6T{]1`HPT%8LQ2_KY4[2](http://iirorwxhjionlo5p.ldycdn.com/cloud/njBpqKrrRlkSoiopokjlj/6RR6T-1-HPT-8LQ2_KY4.png)

![C]LLCKM6_7%(R[{`{6_D]7U](http://iirorwxhjionlo5p.ldycdn.com/cloud/npBpqKrrRlkSoioppkjpj/C-LLCKM6_7-R-6_D-7U.png)

Application

• Cell disrupter (extraction of plant substances, disinfecting, enzyme deactivation)

• Therapeutic ultrasound, i.e. induction of thermolysis in tissues (cancer treatment)

• Decrease of reaction time and/or increase of yield

• Use of less forcing conditions e.g. lower reaction temperature

• Possible switching of reaction pathway

• Use of less or avoidance of phase transfer catalysts

• Degassing forces reactions with gaseous products

• Use of crude or technical reagents

• Activation of metals and solids

• Reduction of any induction period

• Enhancement of the reactivity of reagents or catalysts

• Generation of useful reactive species

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Famous Customers

Catalogue of ultrasonic homogenizer

Ultrasonic homogenizers are powerful and reliable mixers for lab and industry for numerous applications. An ultrasonic homogenizer can be used for various applications, including:

Homogenization: Ultrasonic homogenizers can homogenize samples to create uniform and consistent mixtures.

Dispersion: Ultrasonic homogenizers can be used to disperse solid particles in liquids to create stable suspensions, to get nano-dispersions.

Emulsification: Ultrasonic homogenizers can be used to create stable emulsions and nanoemulsions by breaking up and dispersing immiscible liquids, such as oil and water.

Cell Disruption: Ultrasonic homogenizers can break open cells to extract intracellular components.

Degassing: Ultrasonic homogenizers can be used to remove dissolved gases from liquids. Anti-scaling and descaling, sterilizing,extraction Etc.

Catalogue of ultrasonic homogenizer

Ultrasonic homogenizers are powerful and reliable mixers for lab and industry for numerous applications. An ultrasonic homogenizer can be used for various applications, including:

Homogenization: Ultrasonic homogenizers can homogenize samples to create uniform and consistent mixtures.

Dispersion: Ultrasonic homogenizers can be used to disperse solid particles in liquids to create stable suspensions, to get nano-dispersions.

Emulsification: Ultrasonic homogenizers can be used to create stable emulsions and nanoemulsions by breaking up and dispersing immiscible liquids, such as oil and water.

Cell Disruption: Ultrasonic homogenizers can break open cells to extract intracellular components.

Degassing: Ultrasonic homogenizers can be used to remove dissolved gases from liquids. Anti-scaling and descaling, sterilizing,extraction Etc.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China