- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 69 Author: Site Editor Publish Time: 2021-08-05 Origin: Site

what's the application of ultrasonic in the sewing industry

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: Ultrasonic welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet cloth all need ultrasonic. But in fact, ultrasonic welding and cutting are more than just masks in the sewing industry.

Application 1: For example, the clothes we wear, most of the clothes are not 100% pure cotton, and a certain composition of synthetic materials is added, so it has hot-melt properties. At present, most sewing equipment manufacturers use lasers to cut fabrics. Although laser cutting is very fast, laser cutting is not a real cutting, but the material is divided into two through high-temperature burning, so laser cutting often produces a certain amount of smoke and Burn the material. Ultrasonic wave cutting can perfectly solve this problem. Our cutting knife will generate more than 30,000 vibrations per second while cutting. When it touches the material, it will rub and heat, and the material contacting part will automatically melt the edge. The heat generated by friction heat is just right to melt the edge and will not burn the material. Therefore, the ultrasonic cutting technology can perfectly replace the sewing industry of laser cutting applications and be used for cutting various fabrics.

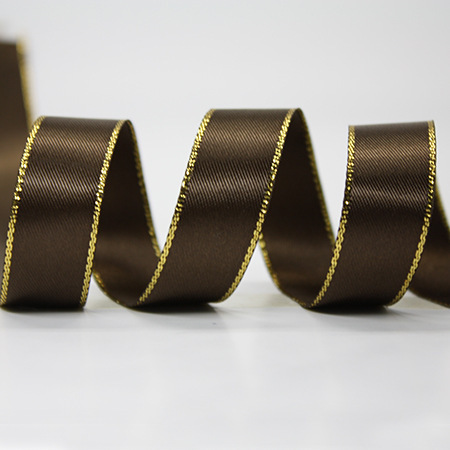

Application 2: Ribbon punching. The ribbons currently on the market are cut by ultrasonic. Satin ribbon is a product made by interweaving warp and weft. Therefore, when cutting ribbons, ribbon filaments or debris are often produced. Ultrasonic cutting can cut and melt the edges at the same time, which perfectly solves this problem.

Application 3: Welding. All kinds of hot-melt materials can be fused by ultrasonic welding, so ultrasonic welding can perfectly replace needle and thread sewing, achieving true seamless welding. Nowadays, the more common non-marking underwear on the market, some manufacturers realize the non-marking through glue. There are two problems with glue. Over time, the glue will lose its viscosity and the material will separate. The second glue cannot avoid the formaldehyde problem, and the production environment is seriously polluted. Therefore, ultrasonic welding is a perfect solution instead of glue, needle and thread, whether it is material cost or environmental protection. In addition to non-marking underwear, all kinds of non-pure cotton materials can be welded by ultrasonic to achieve stitch-free sewing and zero consumables.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China