- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 192 Author: Site Editor Publish Time: 2021-07-07 Origin: Site

What's the application of ultrasonic spray coating?

1. Main applications of ultrasonic spraying:

Electrode coating (FPD and TFT) of imaging display equipment, surface spraying of C-Pt electrode plate of fuel cell, acidification treatment and electrode spraying of photovoltaic cell, deposition process of lithium battery, high-precision lens, glass coating spraying, steel surface heat treatment spraying , Sub-micron, nano-scale film spraying molding, biological preparations, medical antibacterial disinfection, environmental protection coating spraying, PCB flux spraying and other occasions that need to be used for precision coating.

2. Expanded applications of ultrasonic atomization:

Ultrasonic atomization nozzles are often made of highly corrosion-resistant titanium alloy materials, which can effectively resist corrosion of various strong acid (alkali) liquids. Especially some highly oxidizing or corrosive disinfectants, such as spray fumigation and sterilization of hydrogen peroxide, peracetic acid, and formaldehyde, these liquids are highly corrosive to traditional atomization equipment and affect the service life of the equipment. With the help of a certain temperature of compressed gas diffusion, it can be used in medical gasification and disinfection occasions (such as low-temperature VHP sterilizers, low-temperature disinfection rooms, etc.).

Using the principle of ultrasonic atomization spraying, combined with the auxiliary function of hot air or vacuum volatilization, it can realize the spray granulation function from the nanometer or micrometer level.

Using the principle of ultrasonic atomization spraying, the liquid can be sprayed to form a film. Combined with the hot air or vacuum volatilization auxiliary function, it can realize the precise film-forming function from the nanometer or micrometer level, such as PVDF nano film.

3. Types of solutions suitable for ultrasonic spraying:

Pure water solvents, oligomeric alcohols, ketones, aldehyde solvents, dilute acids, dilute alkalis, halogens, low-concentration salts, etc. Among them, the solution with ethanol, acetone and methyl ethyl ketone as the solvent has the best atomization effect.

4. Types of solutions not applicable to ultrasonic spraying:

High-concentration liquid-solid mixture (solid content greater than 60%), polymer polymerization type, such as lipids (such as epoxy resin, polyurethane), polyolefins, etc. In particular, epoxy resin solutions are difficult to atomize and basically cannot achieve uniform atomization.

Ultrasonic spraying machine

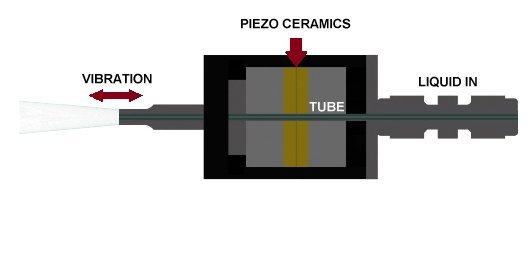

Ultrasonic spraying machine is a kind of coating equipment. The principle is to continuously or automatically coat the surface of the object to be coated with mist-like tiny droplets through a mechanical arm or a guide wheel. It is generally composed of a feeding device, an ultrasonic nozzle, Compressed gas and mobile device composition.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China