- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 88 Author: Site Editor Publish Time: 2024-01-12 Origin: Site

What is Diesel Water Emulsion?

To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another material.

A diesel water emulsion is a mixture of water, diesel fuel, and several additives. It’s important to note that diesel fuel, which is an oil, cannot dissolve in water. This means that when water is dispersed into diesel fuel, it can be emulsified but they will never form a homogeneous liquid.

Where are emulsified fuels used?

The mixture of water, diesel fuel, and several additives, known as the diesel water emulsion, can be used in any diesel engine.

However, it is important to understand that because water has been added to the fuel mixture, the energy that the generator can produce is reduced. Emulsified fuels have a tradeoff where a greater reduction in emissions will correspond to a greater reduction in the generator capacity. The capacity reduction will vary depending on the emissions levels that are trying to be achieved, but typical capacity reductions are around 10-35%.

Often, the combination of using a diesel water emulsion with an efficient diesel generator provides better fuel consumption of the emulsion. In many cases, the benefits of the better fuel consumption and the reduction in harmful engine emissions far outweigh the less-than desirable power reduction of the engine. Beyond the ability to use diesel emulsions as a fuel source, there are secondary benefits, including the mitigation of the high temperatures resulting from combustion as well as the reduction of emissions.

Decreased Combustion Temperatures

In many cases, it is desirable to reduce and control the amount of heat that an engine or generator produces under load. Increased heat can cause premature engine component wear, the breakdown of fluids, and the reduction of the usable lifetime of the equipment. Many studies have shown that using a diesel emulsion as a fuel source can effectively decrease the combustion temperature which yields all of the benefits of a lower operating temperature including the increased engine efficiency, reduced component wear, and increase in the lifetime of the equipment.

The other main benefit of fuel water emulsion decreasing the operation temperature is that this can increase the thermal efficiency of the engine. By definition, thermal efficiency is the ratio of work done by an engine to the amount of heat produced by the fuel and engine over the same work-time. Increased thermal efficiency means cooler running equipment and improved fuel consumption.

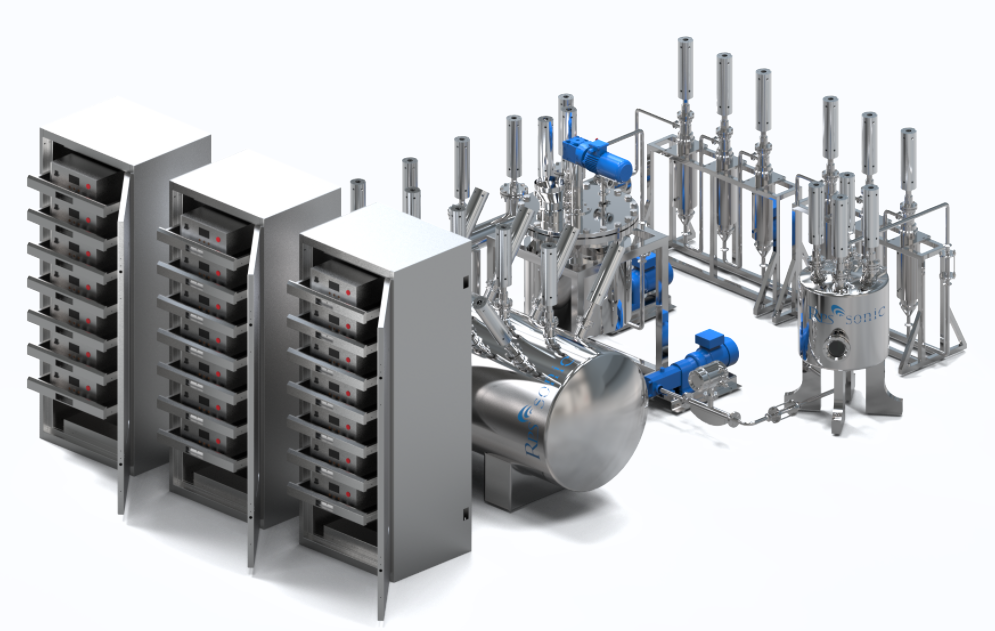

Ultrasonic Water-in-Fuel Emulsions

Power ultrasound is a well known and proven technology to create fine-size emulsions with droplets in the micron and nano range. The ultrasonic emulsification technology is based on cavitational shear forces. By ultrasonic cavitation, the water and fuel droplets are minimized to nano size and are blended together so that a fine-size (nano-/ mini-)emulsion is produced.

For the ultrasonic inline emulsification, the separate fuel and water streams can be precisely adjusted so that a constant ratio of water and fuel is ensured.

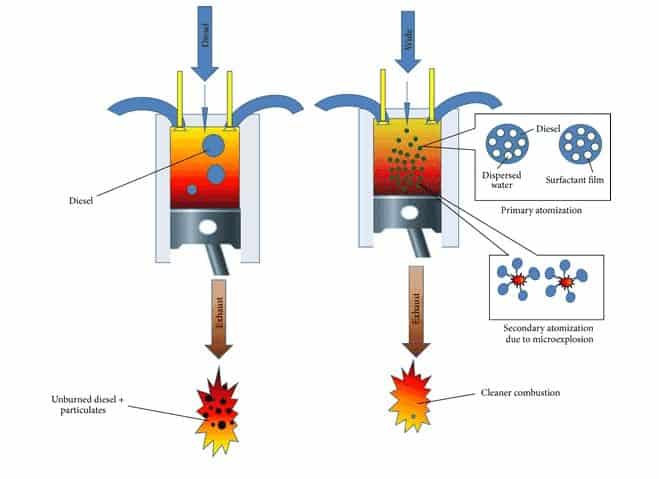

The ultrasonic homogenizers can be installed directly before the injection pump so that the homogeneous water-fuel emulsion can be injected immediately into the engine and the storage of the fuel emulsion is avoided. When the water-fuel emulsion is injected into the combustion chamber, the water droplets evaporate due to the high temperatures rapidly as the boiling point of water is much lower as of the fuel. During the vaporization process, the water droplets burst in a micro-explosive way and disrupt the fuel into smaller droplets.

Thereby, the water-fuel is atomized in the combustion chamber so that fuel and air in the combustion chamber are better mixed and the fuel can be burned completely. The very small droplets offer a very high particle surface resulting in a large low-tension water-oil interface, which improves the atomization further. This increases the combustion efficiency, finally resulting in a significant fuel cost reduction, which exceeds the costs for the emulsification. The ultrasonic blending technology is an inline process, which can be easily retrofitted at existing engines. The engine itself requires no modifications.

Environmental & Economic Benefits:

lower NOx emissions

lower soot emissions

reduced fuel consumption

more complete combustion

lower peak combustion temperatures

less fouling in the boiler

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China