- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 85 Author: Site Editor Publish Time: 2024-01-18 Origin: Site

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices is the coating of various clot activators and anticoagulants on the tube walls to ensure the quality and safety of blood.

These coating materials include heparin, EDTA, silica, and citrate-glucose acid, among others, which prevent blood from clotting or deteriorating inside the tubes, thus affecting blood testing and preservation. If the coating is uneven, inaccurate, or unsuitable, it can lead to blood loss, contamination, or incorrect results, posing significant risks and losses to medical work.

Drawbacks of traditional coating methods.

So, how can we ensure the quality of coatings on blood collection tubes and syringe barrels? Traditional coating methods typically involve the use of air nozzles, but this approach has some serious drawbacks, such as:

Uneven coating, resulting in inconsistent coating thickness on the tube walls, affecting the effectiveness and performance of the coating.

Difficult control of coating thickness, leading to excessive usage and waste of coating materials, increasing production costs and environmental burden.

Severe coating material wastage, causing the coating to extend beyond specific areas on the tube walls and cover the entire tube, unnecessarily affecting the blood inside.

Nozzle clogging issues, resulting in discontinuous and unstable coating, impacting production efficiency and quality.

Faced with these problems, do you feel helpless and confused?

Do you wish for a more advanced, efficient, and precise coating method that can make the manufacturing of your blood collection tubes and syringe barrels more perfect and high-quality?

Dipping-type Blood Collection Tube Coating Nozzle

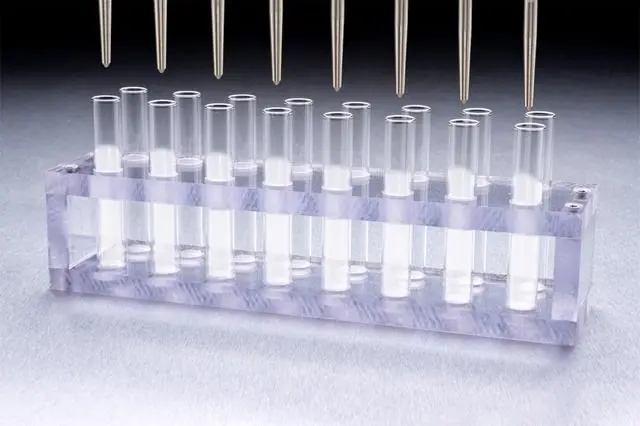

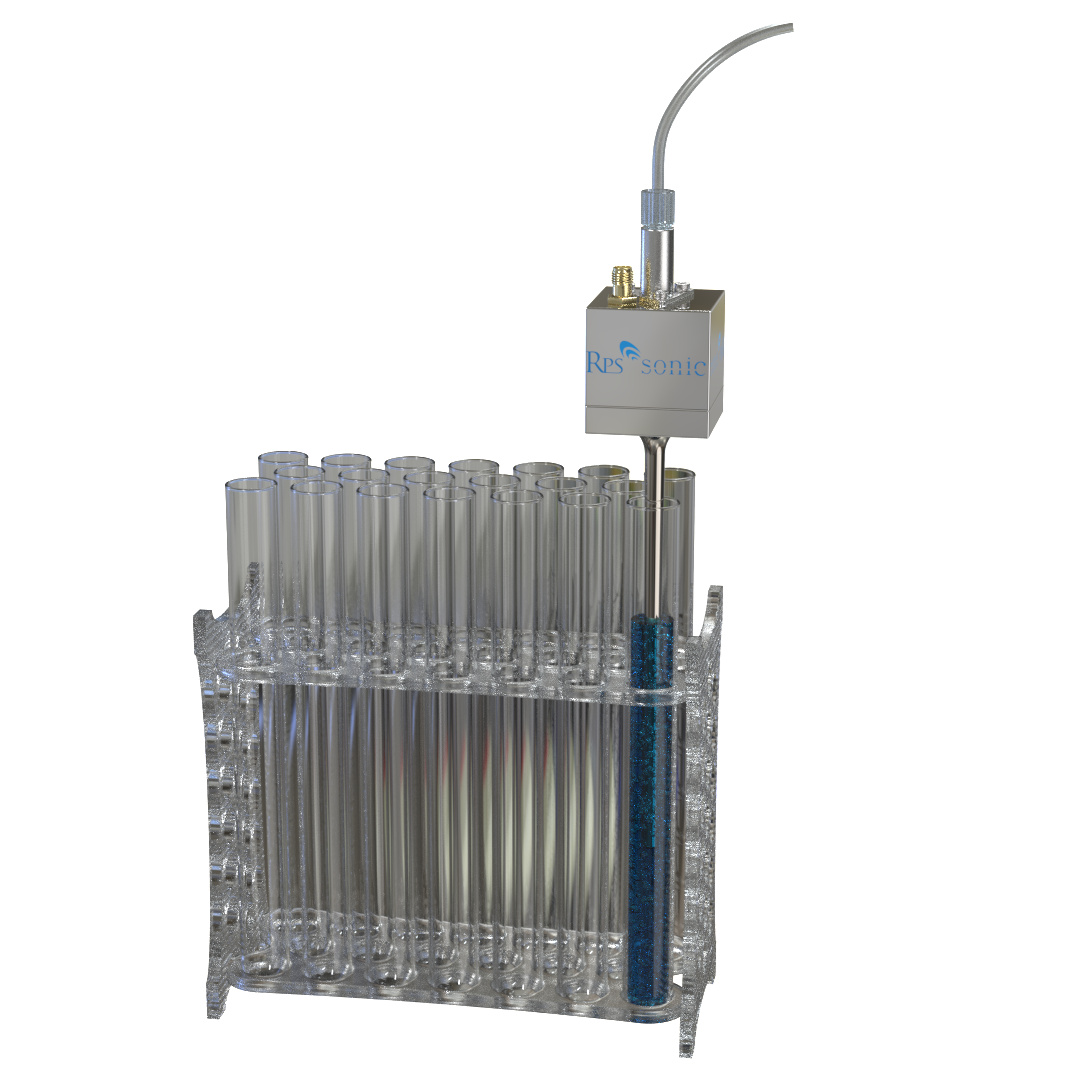

The Dipping-type Blood Collection Tube Coating Nozzle is an ultrasonic atomizing nozzle specifically designed for the coating technology of blood collection tubes (BCT) and syringe barrels. It utilizes the vibration of ultrasonic waves to atomize the liquid coating material into fine droplets, which are then uniformly sprayed onto the tube walls, forming a precise, uniform, and efficient coating.

Characteristics of The dipping-type ultrasonic nozzle :

Ultrasonic atomization technology enables precise control over droplet size and distribution, achieving a highly uniform coating on the tube walls without the need for any rotating or moving mechanism.

The vibration of the ultrasonic nozzle can disperse any solid aggregates in the liquid, ensuring uniform dispersion of the coating material and improving the quality and performance of the coating.

The slim design of the ultrasonic nozzle allows for easy integration into high-volume OEM production lines, enhancing production efficiency and reducing costs.

The integration of the ultrasonic nozzle with ultrasonic generator technology provides excellent coating uniformity and repeatability. The precise tuning capability of the generator produces tighter droplet distribution and smaller droplets, resulting in consistent and rapid drying dispersion.

The ultrasonic nozzle can control the coating area to specific regions on the tube walls, rather than coating the entire tube, reducing the usage and waste of coating materials while avoiding unnecessary impact on the blood inside.

The ultrasonic nozzle has a self-cleaning function, requiring minimal maintenance and extending the nozzle's lifespan.

In summary, the dipping-type nozzle is an innovative ultrasonic spray coating technology for blood collection tubes and syringe barrels, providing an efficient, uniform, and precise solution for their coatings. It meets the production needs of pipeline equipment manufacturers and contributes significantly to the development and innovation in the medical field. This technology not only improves the quality and safety of blood collection tubes and syringe barrels but also saves the usage and cost of coating materials while reducing environmental pollution and risks. The dipping-type nozzle is a coating technology with broad prospects and potential, deserving more attention and application.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China