- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Frequency: | |

|---|---|

| Power: | |

| Material: | |

| Generator : | |

| Availability: | |

| Quantity: | |

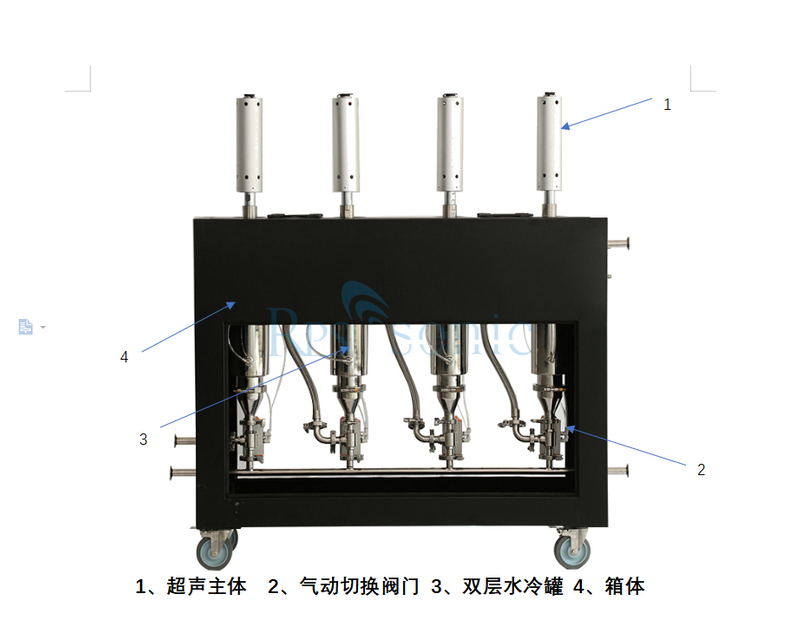

RPS-SONO20

Rps-sonic

RPS-SONO20

Ultrasound Assisted Extraction for Plant Extracion

What's the theory of Ultrasound Assisted Extraction?

Ultrasound refers to those mechanical sound waves whose frequency is higher than 20 kHz and smaller than 10 MHz. Ultrasonic extraction generally uses a reduced range of frequencies (16 kHz-100 kHz) because higher frequencies would result in too much energy that could lead to the degradation of active ingredients in the plant structure.

For this type of extraction, it is necessary that there is a liquid medium that permits the ultrasonic wave to permeate the plant product. Ultrasonic technology allows the complete extraction of plant material, conserving the integrity of all of the molecules contained in the plant, whether they be thermolabile (proteins, amino acids, vitamins, enzymes, etc.), thermostable, water-soluble, or fat-soluble. This is made possible because the vibration of the ultrasonic waves that provokes the mechanical breakdown of the cell walls. One obtains a stable totem mixture of the molecules contained in the plant cell in a just a few minutes.

Often, to make the extraction more efficient, one proceeds with a preventative grinding of the plant material: the plants become shredded through common mills, and successively premixed with the solvent. In this way, the liquid used already begins to soak in the plant matter, increasing its volume. This operation becomes very important when one is in the presence of very durable or tough vegetable matter (cortices, roots, seeds, etc.).

For the entire time of extraction, the plant material is maintained in suspension with a light agitation in order to let the ultrasound penetrate all parts of the plant.

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm⊃2; | 40 W/cm⊃2; | 60 W/cm⊃2; | 60 W/cm⊃2; |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

PRINCIPLE ADVANTAGES OF EXTRACTION THROUGH ULTRASOUND WITH RESPECT TO CONVENTIONAL MACERATION:

Substantial reduction in production time, because the ultrasounds traveling to break the cell walls diminish the transfer time of the active ingredients from the plant material to the solvent. It is possible to obtain a liter of macerated solution in only 15 minutes.

It is an extractive technique that has been given the “bio” accreditation, being solely a physical extraction process with no added chemicals. It uses only natural solvents (oil, water, and alcohol) independent of the solubility of the active ingredients. Very satisfactory yields are obtained in terms of active ingredients since there is almost complete depletion of the plant material.

However, with ultrasounds it is not possible to achieve a selective extraction because there is a complete discharge of all the molecules contained in the plant matter independent of the affinity with the solvent used. If you want to get the separation of the active ingredients contained in the plant mass, subsequent methods must be carried out.

For more inforation, Kindly check the catalogue as follows:

Catalogue of laboratory sonochemistry Catalogue of industry sonochemistry

Ultrasound Assisted Extraction for Plant Extracion

What's the theory of Ultrasound Assisted Extraction?

Ultrasound refers to those mechanical sound waves whose frequency is higher than 20 kHz and smaller than 10 MHz. Ultrasonic extraction generally uses a reduced range of frequencies (16 kHz-100 kHz) because higher frequencies would result in too much energy that could lead to the degradation of active ingredients in the plant structure.

For this type of extraction, it is necessary that there is a liquid medium that permits the ultrasonic wave to permeate the plant product. Ultrasonic technology allows the complete extraction of plant material, conserving the integrity of all of the molecules contained in the plant, whether they be thermolabile (proteins, amino acids, vitamins, enzymes, etc.), thermostable, water-soluble, or fat-soluble. This is made possible because the vibration of the ultrasonic waves that provokes the mechanical breakdown of the cell walls. One obtains a stable totem mixture of the molecules contained in the plant cell in a just a few minutes.

Often, to make the extraction more efficient, one proceeds with a preventative grinding of the plant material: the plants become shredded through common mills, and successively premixed with the solvent. In this way, the liquid used already begins to soak in the plant matter, increasing its volume. This operation becomes very important when one is in the presence of very durable or tough vegetable matter (cortices, roots, seeds, etc.).

For the entire time of extraction, the plant material is maintained in suspension with a light agitation in order to let the ultrasound penetrate all parts of the plant.

Parameter

Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

Power | 1000 W | 2000 W | 3000 W | 3000 W |

Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | 20 W/cm⊃2; | 40 W/cm⊃2; | 60 W/cm⊃2; | 60 W/cm⊃2; |

Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

PRINCIPLE ADVANTAGES OF EXTRACTION THROUGH ULTRASOUND WITH RESPECT TO CONVENTIONAL MACERATION:

Substantial reduction in production time, because the ultrasounds traveling to break the cell walls diminish the transfer time of the active ingredients from the plant material to the solvent. It is possible to obtain a liter of macerated solution in only 15 minutes.

It is an extractive technique that has been given the “bio” accreditation, being solely a physical extraction process with no added chemicals. It uses only natural solvents (oil, water, and alcohol) independent of the solubility of the active ingredients. Very satisfactory yields are obtained in terms of active ingredients since there is almost complete depletion of the plant material.

However, with ultrasounds it is not possible to achieve a selective extraction because there is a complete discharge of all the molecules contained in the plant matter independent of the affinity with the solvent used. If you want to get the separation of the active ingredients contained in the plant mass, subsequent methods must be carried out.

For more inforation, Kindly check the catalogue as follows:

Catalogue of laboratory sonochemistry Catalogue of industry sonochemistry

Sonochemical reactions

Three classes of sonochemical reactions exist: homogeneous sonochemistry of liquids, heterogeneous sonochemistry of liquid-liquid or solid–liquid systems, and, overlapping with the aforementioned, sonocatalysis (the catalysis or increasing the rate of a chemical reaction with ultrasound). Sonoluminescence is a consequence of the same cavitation phenomena that is responsible for homogeneous sonochemistry. The chemical enhancement of reactions by ultrasound has been explored and has beneficial applications in mixed phase synthesis, materials chemistry, and biomedical uses. Because cavitation can only occur in liquids, chemical reactions are not seen in the ultrasonic irradiation of solids or solid–gas systems.

For example, in chemical kinetics, it has been observed that ultrasound can greatly enhance chemical reactivity in a number of systems by as much as a million-fold;[16] effectively acting to activate heterogeneous catalysts. In addition, in reactions at liquid-solid interfaces, ultrasound breaks up the solid pieces and exposes active clean surfaces through microjet pitting from cavitation near the surfaces and from fragmentation of solids by cavitation collapse nearby. This gives the solid reactant a larger surface area of active surfaces for the reaction to proceed over, increasing the observed rate of reaction.

While the application of ultrasound often generates mixtures of products, a paper published in 2007 in the journal Nature described the use of ultrasound to selectively affect a certain cyclobutane ring-opening reaction. Atul Kumar has reported multicomponent reaction Hantzsch ester synthesis in Aqueous Micelles using ultrasound.

Some water pollutants, especially chlorinated organic compounds, can be destroyed sonochemically.

Sonochemistry can be performed by using a bath (usually used for ultrasonic cleaning) or with a high power probe, called an ultrasonic horn, which funnels and couples a piezoelectric element's energy int

See also

Ultrasound

Sonication

Ultrasonics

ultrasonic homogenizer

homogenizer

Homogenization (chemistry)

Sonoelectrochemistry

Kenneth S. Suslick

Sonochemical reactions

Three classes of sonochemical reactions exist: homogeneous sonochemistry of liquids, heterogeneous sonochemistry of liquid-liquid or solid–liquid systems, and, overlapping with the aforementioned, sonocatalysis (the catalysis or increasing the rate of a chemical reaction with ultrasound). Sonoluminescence is a consequence of the same cavitation phenomena that is responsible for homogeneous sonochemistry. The chemical enhancement of reactions by ultrasound has been explored and has beneficial applications in mixed phase synthesis, materials chemistry, and biomedical uses. Because cavitation can only occur in liquids, chemical reactions are not seen in the ultrasonic irradiation of solids or solid–gas systems.

For example, in chemical kinetics, it has been observed that ultrasound can greatly enhance chemical reactivity in a number of systems by as much as a million-fold;[16] effectively acting to activate heterogeneous catalysts. In addition, in reactions at liquid-solid interfaces, ultrasound breaks up the solid pieces and exposes active clean surfaces through microjet pitting from cavitation near the surfaces and from fragmentation of solids by cavitation collapse nearby. This gives the solid reactant a larger surface area of active surfaces for the reaction to proceed over, increasing the observed rate of reaction.

While the application of ultrasound often generates mixtures of products, a paper published in 2007 in the journal Nature described the use of ultrasound to selectively affect a certain cyclobutane ring-opening reaction. Atul Kumar has reported multicomponent reaction Hantzsch ester synthesis in Aqueous Micelles using ultrasound.

Some water pollutants, especially chlorinated organic compounds, can be destroyed sonochemically.

Sonochemistry can be performed by using a bath (usually used for ultrasonic cleaning) or with a high power probe, called an ultrasonic horn, which funnels and couples a piezoelectric element's energy int

See also

Ultrasound

Sonication

Ultrasonics

ultrasonic homogenizer

homogenizer

Homogenization (chemistry)

Sonoelectrochemistry

Kenneth S. Suslick

1. Can your sonochemistry horn be used in an acid (alkali) environment?

Under the acid (alkali) environment, the horn need to be customized according to the actual working conditions of customers.

2. Can the ultrasonic sonochemistry work continuously?

Yes , it can work 24hours continue.

3. What kind of material is the horn?

Titanium alloy, we also customized ceramic horn for customer before.

4. What’s the time of delivery

For Conventional horn, 3 days, for customized horn 7 work days.

5. Does ultrasonic extraction also require the addition of a chemical catalyst?

No , but some time need Mechanical stirring.

6. What’s the advantage of ultrasonic extraction?

Decline the extraction time, and increase the extraction ratio.

7. What’s the Processing capacity of one set ultrasonic extraction equipment?

Different horn different Processing capacity, for 2000W Nine-section whip horn can dealing 2L~10L/min.

8. Are you manufacturer?

We only manufacturer the transducer and generator our-self, for the horn , we design and buy raw material ,and process by other companies.

9. What’s the warranty of your sonochemistry equipment?

All equipment one year warranty.

10. Do you have Foreign agent?

Yes, we have agent in Mexico, also We have OEM customer in USA and Germany.

11. Is it difficult to install the ultrasonic sonochemistry equipment?

No , it is easy , we will share Installation diagram, also can take install video for you.

1. Can your sonochemistry horn be used in an acid (alkali) environment?

Under the acid (alkali) environment, the horn need to be customized according to the actual working conditions of customers.

2. Can the ultrasonic sonochemistry work continuously?

Yes , it can work 24hours continue.

3. What kind of material is the horn?

Titanium alloy, we also customized ceramic horn for customer before.

4. What’s the time of delivery

For Conventional horn, 3 days, for customized horn 7 work days.

5. Does ultrasonic extraction also require the addition of a chemical catalyst?

No , but some time need Mechanical stirring.

6. What’s the advantage of ultrasonic extraction?

Decline the extraction time, and increase the extraction ratio.

7. What’s the Processing capacity of one set ultrasonic extraction equipment?

Different horn different Processing capacity, for 2000W Nine-section whip horn can dealing 2L~10L/min.

8. Are you manufacturer?

We only manufacturer the transducer and generator our-self, for the horn , we design and buy raw material ,and process by other companies.

9. What’s the warranty of your sonochemistry equipment?

All equipment one year warranty.

10. Do you have Foreign agent?

Yes, we have agent in Mexico, also We have OEM customer in USA and Germany.

11. Is it difficult to install the ultrasonic sonochemistry equipment?

No , it is easy , we will share Installation diagram, also can take install video for you.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China