- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Frequency: | |

|---|---|

| Power: | |

| width: | |

| horn material : | |

| Availability: | |

| Quantity: | |

C20-305

Rps-sonic

C20-305

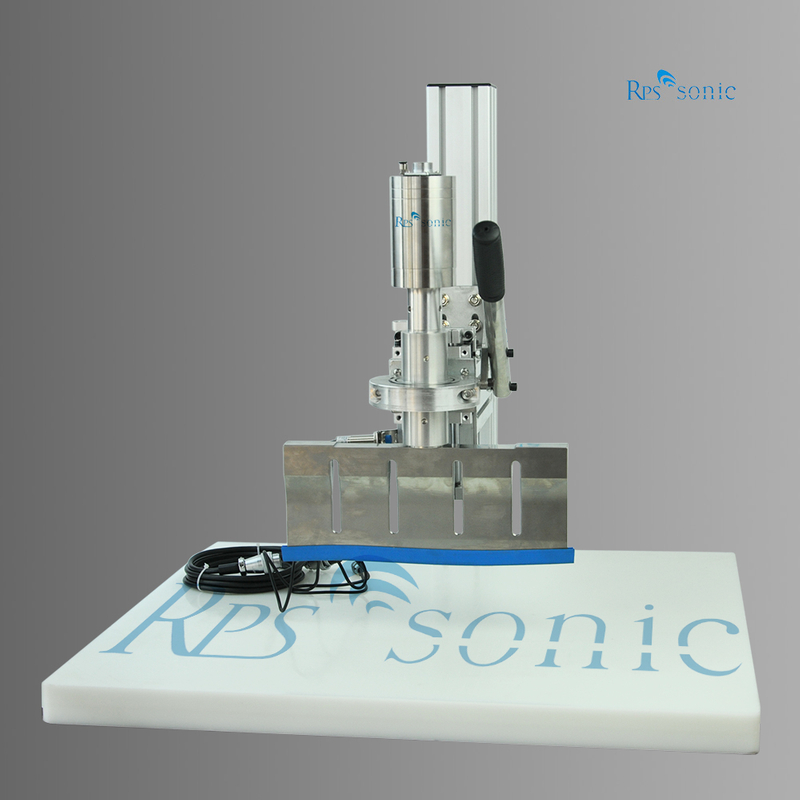

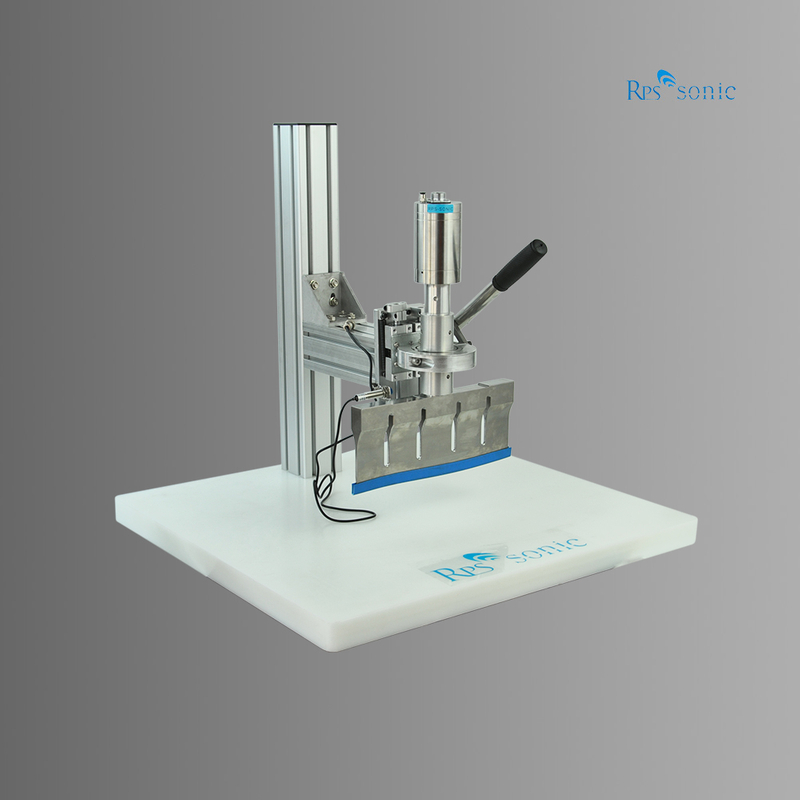

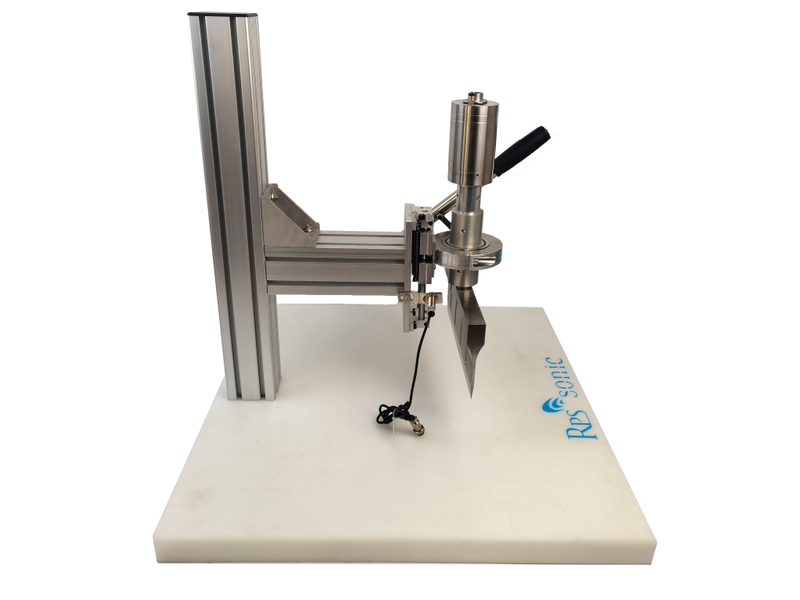

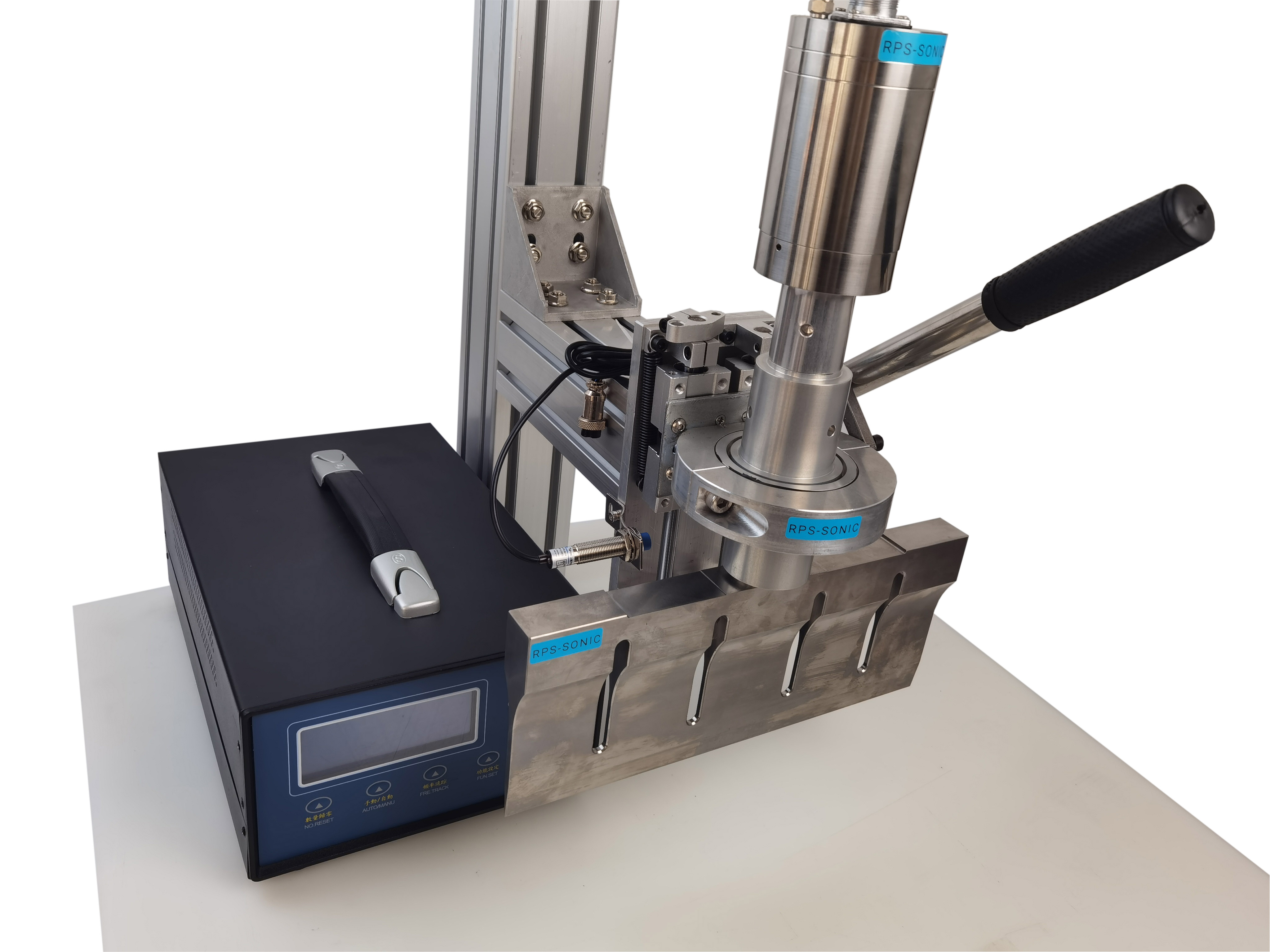

Economy Ultrasonic Food Cutting Equipment for Bakery Frozen Food

What's the principle of ultrasonic cutting?

Bakery products containing cream or sugary layers, as well as other dough or fat-containing foods, can be cut or trimmed in a controlled way by ultrasound to produce a quality that is visually appealing. The cutting geometries of the tools for longitudinal or cross cuts are individually tailored to product requirements.

As a result of ultrasonic vibrations, only slight product residues remain adhered to the sonotrode, so that to a certain extent, it demonstrates a self-cleaning action.

Because of the ultrasonic vibrations, cutting sonotrodes work with a lower initial pressure than conventional cutters. At the same time, sonotrode wear is less and the cutting quality is considerably better. In addition, the use of ultrasonic cutting systems has a positive effect on the maintenance and down times of the equipment.

The ultrasonic cutter cutter directly loads the ultrasonic energy onto the cutter, and the cutter becomes a cutter with ultrasonic waves. When cutting the material, the material is mainly softened and melted by the ultrasonic energy, and the cutting edge of the cutter only serves as the slit positioning, the ultrasonic energy output, and the separation material. This cutting method is suitable for cutting thick, thick, long, etc. materials that are inconvenient to set the cutting board. Such as raw rubber output from the rubber mixer, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, or hand-held cutting machines.

The basic structure of the ultrasonic cutting board cutter is similar to that of the ultrasonic cutter cutter, except that the ultrasonic output portion is not a cutter but a standard ultrasonic flat mold. Here, the mold is equivalent to a cutting board. However, this is a cutting board that is used for ultrasonic vibration. The cutting knife can still be used in the traditional shape, but the sharpness of the cutting edge is reduced, and the life of the cutting knife is greatly extended.

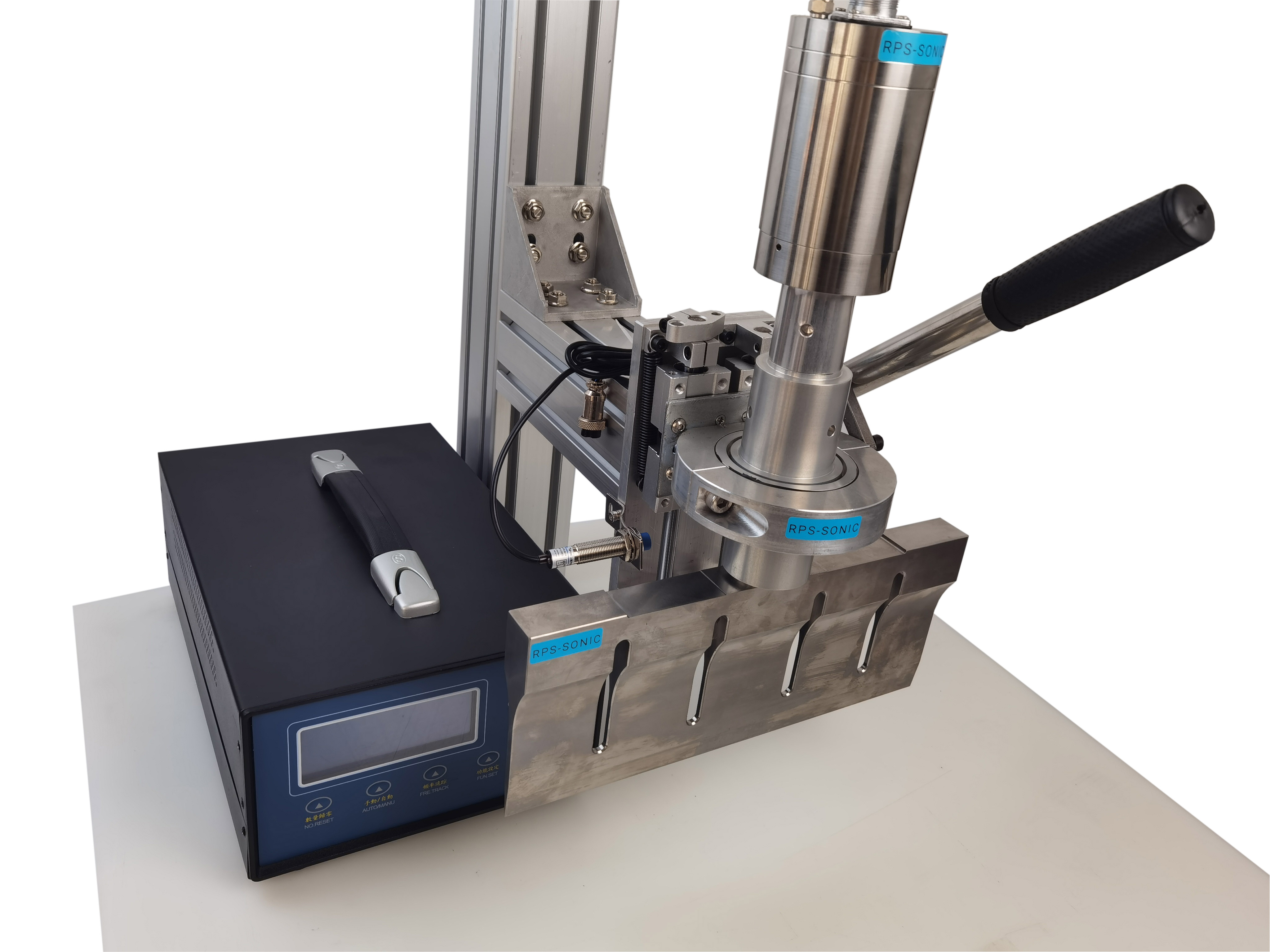

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

Pleasing cut and form stability

Product-specific cutting geometries

Cutting sonotrodes with little product adhesion and self-cleaning action

Reduction in maintenance and down times

Products cut almost irrespective of consistency

Applications:

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

Economy Ultrasonic Food Cutting Equipment for Bakery Frozen Food

What's the principle of ultrasonic cutting?

Bakery products containing cream or sugary layers, as well as other dough or fat-containing foods, can be cut or trimmed in a controlled way by ultrasound to produce a quality that is visually appealing. The cutting geometries of the tools for longitudinal or cross cuts are individually tailored to product requirements.

As a result of ultrasonic vibrations, only slight product residues remain adhered to the sonotrode, so that to a certain extent, it demonstrates a self-cleaning action.

Because of the ultrasonic vibrations, cutting sonotrodes work with a lower initial pressure than conventional cutters. At the same time, sonotrode wear is less and the cutting quality is considerably better. In addition, the use of ultrasonic cutting systems has a positive effect on the maintenance and down times of the equipment.

The ultrasonic cutter cutter directly loads the ultrasonic energy onto the cutter, and the cutter becomes a cutter with ultrasonic waves. When cutting the material, the material is mainly softened and melted by the ultrasonic energy, and the cutting edge of the cutter only serves as the slit positioning, the ultrasonic energy output, and the separation material. This cutting method is suitable for cutting thick, thick, long, etc. materials that are inconvenient to set the cutting board. Such as raw rubber output from the rubber mixer, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, or hand-held cutting machines.

The basic structure of the ultrasonic cutting board cutter is similar to that of the ultrasonic cutter cutter, except that the ultrasonic output portion is not a cutter but a standard ultrasonic flat mold. Here, the mold is equivalent to a cutting board. However, this is a cutting board that is used for ultrasonic vibration. The cutting knife can still be used in the traditional shape, but the sharpness of the cutting edge is reduced, and the life of the cutting knife is greatly extended.

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

Pleasing cut and form stability

Product-specific cutting geometries

Cutting sonotrodes with little product adhesion and self-cleaning action

Reduction in maintenance and down times

Products cut almost irrespective of consistency

Applications:

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

1. What’s the warranty of your ultrasonic cutter?

Our warranty is one year , but we can supply you Components free even out of warranty.

2. What’s frequency ultrasonic cutter you supply?

We can supply generatorr from 20~40khz depending on your requirements or application.

4. What’s the using life of your ultrasonic cutting equipment?

Under correct working environment, our ultrasonic cutter can work 3~5 years

5. Does your products exported before?

Yes, our Generator exported to USA,south America, EUROPE, Middle East, and Russia for many years.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. How to customize blades ?

you can tell us your dimension requirements, we will customize depending on your requirements.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

1. What’s the warranty of your ultrasonic cutter?

Our warranty is one year , but we can supply you Components free even out of warranty.

2. What’s frequency ultrasonic cutter you supply?

We can supply generatorr from 20~40khz depending on your requirements or application.

4. What’s the using life of your ultrasonic cutting equipment?

Under correct working environment, our ultrasonic cutter can work 3~5 years

5. Does your products exported before?

Yes, our Generator exported to USA,south America, EUROPE, Middle East, and Russia for many years.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. How to customize blades ?

you can tell us your dimension requirements, we will customize depending on your requirements.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

| Frequency | Blade width | generator | Horn material | Application |

| 20kHZ | 305MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 255MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 200MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 150MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 50-100MM | 2000CS | Titanium alloy | Food cutting & Rubber cutting |

| 35Khz | 82.5MM | 2000CS | Titanium alloy | Food cutting & Rubber cutting |

| Frequency | Blade width | generator | Horn material | Application |

| 20kHZ | 305MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 255MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 200MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 150MM | 2000CS | Titanium alloy | Food cutting |

| 20kHZ | 50-100MM | 2000CS | Titanium alloy | Food cutting & Rubber cutting |

| 35Khz | 82.5MM | 2000CS | Titanium alloy | Food cutting & Rubber cutting |

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China