- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 490 Author: Site Editor Publish Time: 2019-07-17 Origin: Site

Why does the welding horn fail? You should understand these

The welding horn plays a key role in ultrasonic welding. But what kind of "tool" is the welding horn, and what is its role? Let us introduce them one by one.

The horn is a tool that effectively transmits vibration to the plastic weld. It has the following features:

· Transfer vibration energy

· Passing pressure

· Pass amplitude

· Provides a shape that conforms to the shape of the product, and because the plastic is malleable, it can fit the product to a certain extent.

The design and manufacture of the welding horn must be very careful, as only good welding horns can guarantee good welding results. If the design of the welding horn is poor (amplitude design, unreasonable vibration mode), poor manufacturing (material selection, improper frequency modification) may cause the welding horn to break.

Different size welding horns

Weld horn material selection and restrictions

Typically, the weld horn is made from three different materials, each with its own unique properties. Choose according to usage requirements and expectations.

· Aluminium alloy: used in the soft mold verification process stage or small batch production stage, can not withstand mechanical stress. Or a large weld horn for weight and cost is an important consideration. This is one of the most commonly used materials with good mechanical properties (hardness and ultrasonic propagation speed) and economy.

· Titanium alloy: It is used in the small, medium and large-scale production stage of the product. It has excellent acoustic performance, can withstand the maximum mechanical stress of 3 times that of aluminum alloy, and has relatively excellent wear resistance. At the same time, the wear resistance can be greatly increased by performing a specific surface treatment on the surface of the horn. Often used for welding with fiberglass plastics.

· Alloy steel: used for welding of plastic parts that cannot be applied to aluminum alloys and titanium alloys. It has high hardness and highest wear resistance and is hardened before use. This material is often used in applications where ultrasonic metal screws are embedded.

In order to obtain the best welding results, it is not recommended to use large ultrasonic welding horn . Because the vibration surface amplitude output of large horns cannot be strictly consistent, it is recommended to use a mother-fed horn or multiple individual horns for welding when welding large products. The following points should also be noted when using the welding horn:

· Aluminum alloy welding horn amplitude output ≤ 60μm;

· Titanium alloy welding horn, for a simple round welding horn, the maximum output amplitude is 90-120μm;

· For large horns, the addition of grooves on the end face of the horn helps to make the amplitude output more uniform, while the maximum output amplitude is ≤60μm;

· For large-scale mother-fed welding horns, the amplitude of the female welding horn is ≤40μm;

· Need to avoid sharp edges. All weld horn edges must be rounded to avoid breakage;

· The welding horn must be assembled using the appropriate tools.

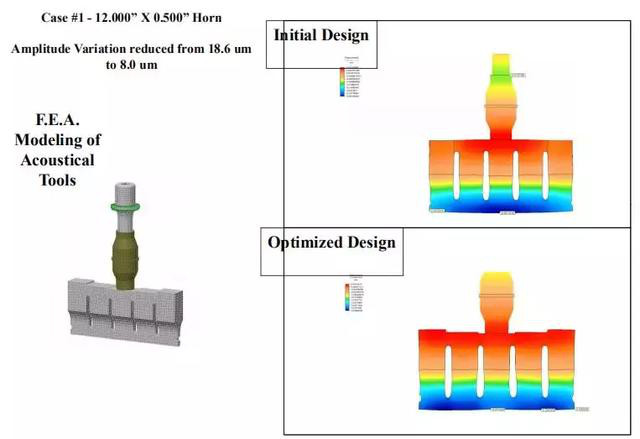

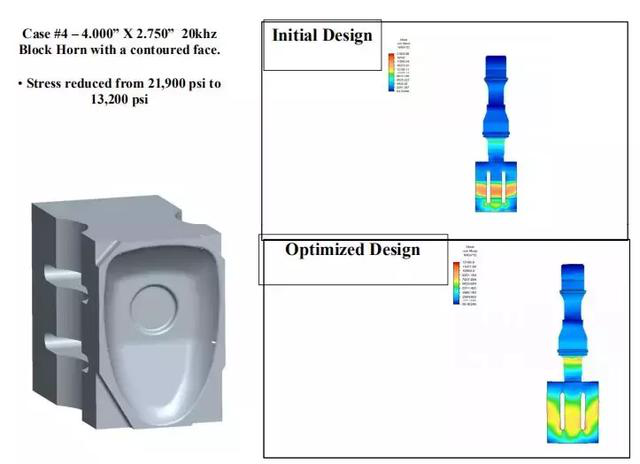

FEA evaluates weld horn quality and optimizes

Using advanced FEA finite element simulation, it is possible to perform failure analysis on the weld horn during the design phase, evaluate and optimize the vibration behavior of the weld horn, output amplitude uniformity, and maximum stress. Tests have proven that the weld horn can be accurately evaluated, greatly improving the reliability of the weld horn.

FEA welding horn vibration and amplitude optimization case

Optimization of stress distribution of welding horn using FEA

Type and characteristics of the welding horn

There are different types of weld horns to suit different application needs. For example, a small, high-gain (high-amplitude output) round weld horn is used to weld small rectangular parts; a large rectangular weld horn outputs a small amplitude for welding large parts. The most common types are as follows:

· Stepped Horn: There are different sections at both ends of the weld horn, and the two sections are rounded at the position of the weld horn. The stepped horn has a high gain and large amplitude output because of a sudden change in the plane of the node plane, and the mechanical stress is also large. This type of welding horn is suitable for ultrasonic welding, riveting, shedding and other processes.

· Exponential Horn: The shape of the weld horn changes according to an exponential formula. The cross section gradually transitions, distributing internal stresses over longer areas to reduce peak stress. Therefore, such a welding horn has an ideal stress distribution and excellent fatigue strength. Suitable for applications where welding pressure is high and amplitude output is small, such as metal screw inlays.

· Catenoid Weld Horn: Combines the advantages of stepped high gain and exponential low stress. Suitable for welding and riveting various small parts.

· Rectangular or Bar weld horns: common designs. Small-sized rectangular horns are also usually stepped. In general, the width of the horn is greater than 88mm. In order to avoid lateral vibration and stress of the horn, it is necessary to add grooves to the structure. The standard rectangular horn can be up to 250mm in size.

· Circular Horn: Includes hollow or solid horns. It is usually used for plastic parts that are round in the welded area. Circular horns with diameters greater than 88 mm typically add slots to allow for axial vibration.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China