- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 338 Author: Site Editor Publish Time: 2021-07-07 Origin: Site

What is ultrasonic spray coating?

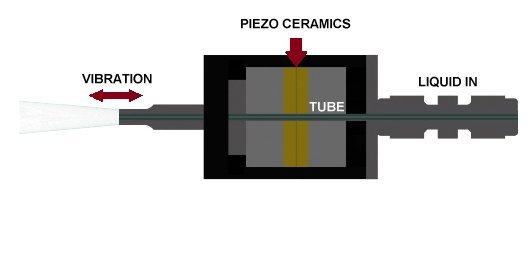

Ultrasonic spraying , also known as ultrasonic coating, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomization device, and then uniformly coated on the surface of the substrate by a certain amount of carrier gas , Thereby forming a coating or film. The biggest difference between ultrasonic spraying and traditional single-fluid or two-fluid spraying is that the atomizing device or atomizing nozzle adopts an ultrasonic atomizing device, that is, an ultrasonic nozzle.

Compared with traditional two-fluid spraying, ultrasonic spraying has the advantages of high coating uniformity, high raw material utilization, high coating thickness control accuracy, thinner coating thickness, less splashing, no clogging of nozzles, and low maintenance costs. Compared with coating processes such as vacuum evaporation and CVD, ultrasonic spraying is a more economical thin film coating process, especially in the preparation of large-area thin films, the equipment cost of ultrasonic spraying is lower than that of vacuum coating equipment.

The main advantages of ultrasonic spraying are:

1. High coating uniformity

The uniformity of the distribution of liquid particles atomized by the ultrasonic spray nozzle is significantly higher than that of the two-fluid nozzle, which is commonly known as the air spray gun, so that the uniformity of the coating after spraying by the ultrasonic nozzle is improved. Under normal circumstances, the uniformity of the coating of ultrasonic spraying can reach more than 95%.

2. High raw material utilization rate, less splash

Since ultrasonic spraying is liquid atomization by ultrasonic transducer, the process of coating atomization does not require any gas, that is, the atomization process does not require pressure, and only a very low carrier gas pressure is applied to transport the liquid mist after atomization. It greatly reduces the liquid rebound and splash caused by the two-fluid spraying high-pressure air, thereby greatly improving the utilization rate of the coating. The raw material utilization rate of ultrasonic spraying is more than 4 times that of ordinary air spraying, and the utilization rate can reach more than 90%.

3. High precision of coating thickness control

The main factor affecting the accuracy of the coating thickness is the spraying flow rate of the coating, which is the amount of material loaded on the substrate per unit time. The ultrasonic nozzle has no pressure effect on the liquid, so the flow rate of the sprayed coating liquid can be completely controlled by the high-precision metering pump, thereby realizing high-precision spraying flow control. For example, a high-precision syringe pump has a flow control accuracy of up to picoliters per second, and the micro-channel design of the ultrasonic nozzle can also achieve the overall control accuracy of nanoliters per second.

4. The coating thickness is thin, up to tens of nanometers

Since the spray volume of the ultrasonic nozzle can achieve a very low and stable flow rate (0.001ml/min), it can achieve a very small amount of loading on the substrate, thereby realizing a very thin dry film. For some nanomaterials, the dry film thickness can be as low as tens of nanometers. It can be used to prepare glass films such as transparent conductive film, antireflection and antireflection film, heat insulation film, hydrophilic and hydrophobic film.

5. The nozzle is not clogged and the maintenance cost is low

Since the ultrasonic nozzle achieves liquid atomization through ultrasonic transducer, and the atomized particles are determined by the ultrasonic transducer frequency, it is different from the two-fluid nozzle. The nozzle diameter does not need to be small to achieve fine atomized particles, so it reduces The risk of nozzle clogging is eliminated.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China