- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Frequency: | |

|---|---|

| replace for : | |

| Material: | |

| Availability: | |

| Quantity: | |

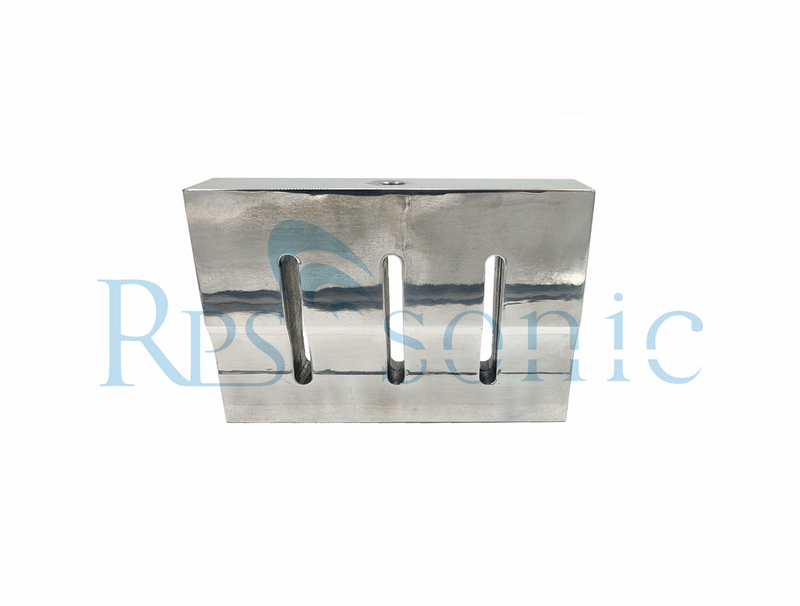

Rps-H15

Rps-sonic

Rps-H15

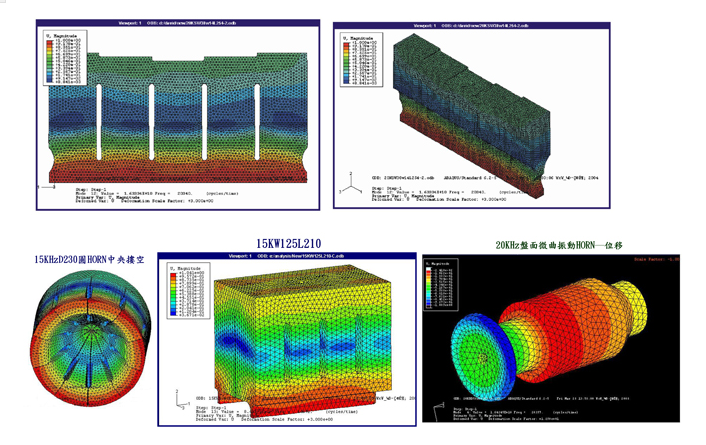

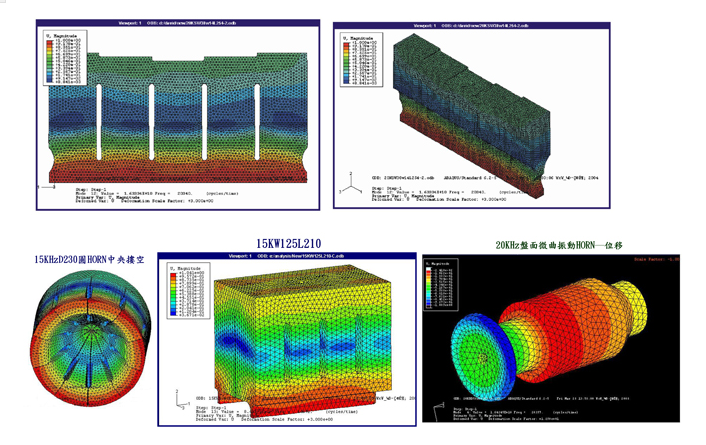

Using Finite Element Analysis (Finite Element Analysis (FEA) software, each weld horn is analyzed in the most detailed and optimized manner to achieve the best vibration and life.

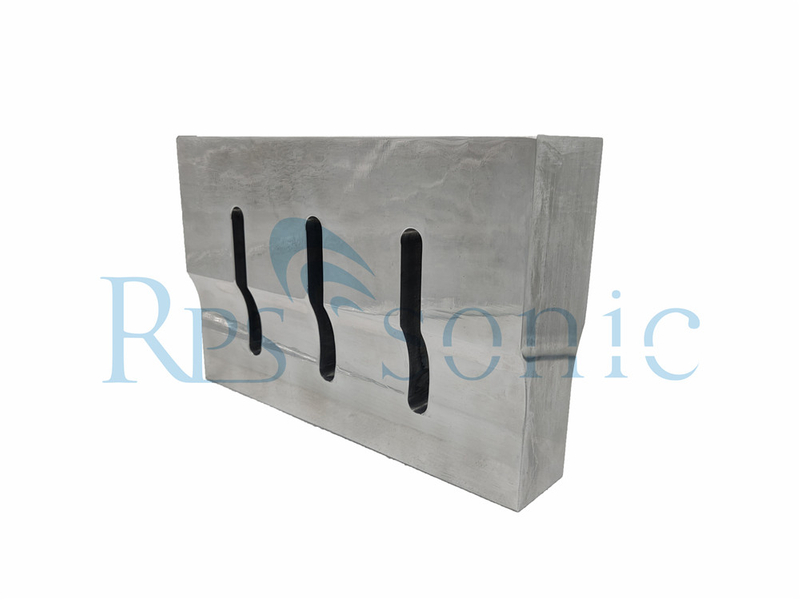

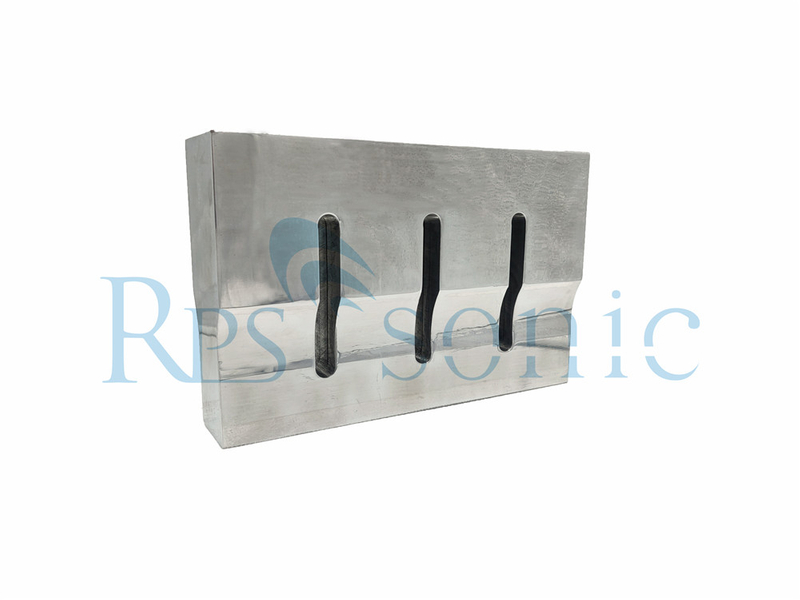

Each weld horn, whether it is a standard weld head or a custom weld head, uses the best quality materials, the best design and the most precise adjustments as standard. All weld horns are supplied with safe stock to meet the needs of our customers' different types of weld horns. Various welding horn frequencies from 15KHz to 100KHz can be produced by our company. The type of welding horn includes step type, overhang surface type, exponential type, rectangular type, round type, hollow type, and the like.

For the production of special welding horns, the company analyzes the vibration state and stress distribution of each welding horn with finite element analysis (FEA) software, to ensure that each welding horn achieves the best quality to meet the various applications of customers. Requirements, including the mother and the welding horn, the torsion welding horn, various irregular shapes and the welding horn design for special applications.

uirements include sub-weld horns, torsion horns, various irregular shapes and horn designs for special applications.

We can supply ultrasonic horn in 15KHz, 20KHz, 28KHz, 30KHz, 35KHz, 40KHz, 56KHz, etc.

Can be designed according to customer specifications

What's ultrasonic booster?

Ultrasonic Transducer Horn Ultrasonic Horn Design Guidelines, the important component of the ultrasonic vibration system is to amplify the mass displacement or velocity of the mechanical vibration and concentrate the ultrasonic energy on a small area. Ultrasonic booster is an important part of the ultrasonic vibration system. Its main function in the vibration system is to amplify the mass displacement or velocity of the mechanical vibration, and concentrate the ultrasonic energy on a small area, that is, the energy is collected. Also known as ultrasonic shift levers or ultrasonic concentrators.

Ultrasonic booster, as the name suggests, are functional components that match the amplitude of ultrasonic vibrations with ultrasonic transducers. Its main function is to change the amplitude of the transducer (generally increase), improve the vibration ratio, improve the efficiency, improve the mechanical quality factor, enhance the heat resistance, expand the temperature range, and prolong the service life of the transducer. The ultrasonic transducer adjusts the load matching between the transducer and the ultrasonic horn by installing a booster, which reduces the resonance impedance and makes it work at the resonant frequency to improve the electro-acoustic conversion efficiency. Reduces the heat generation of the ultrasonic transducer and improves the service life.

Using Finite Element Analysis (Finite Element Analysis (FEA) software, each weld horn is analyzed in the most detailed and optimized manner to achieve the best vibration and life.

Each weld horn, whether it is a standard weld head or a custom weld head, uses the best quality materials, the best design and the most precise adjustments as standard. All weld horns are supplied with safe stock to meet the needs of our customers' different types of weld horns. Various welding horn frequencies from 15KHz to 100KHz can be produced by our company. The type of welding horn includes step type, overhang surface type, exponential type, rectangular type, round type, hollow type, and the like.

For the production of special welding horns, the company analyzes the vibration state and stress distribution of each welding horn with finite element analysis (FEA) software, to ensure that each welding horn achieves the best quality to meet the various applications of customers. Requirements, including the mother and the welding horn, the torsion welding horn, various irregular shapes and the welding horn design for special applications.

uirements include sub-weld horns, torsion horns, various irregular shapes and horn designs for special applications.

We can supply ultrasonic horn in 15KHz, 20KHz, 28KHz, 30KHz, 35KHz, 40KHz, 56KHz, etc.

Can be designed according to customer specifications

What's ultrasonic booster?

Ultrasonic Transducer Horn Ultrasonic Horn Design Guidelines, the important component of the ultrasonic vibration system is to amplify the mass displacement or velocity of the mechanical vibration and concentrate the ultrasonic energy on a small area. Ultrasonic booster is an important part of the ultrasonic vibration system. Its main function in the vibration system is to amplify the mass displacement or velocity of the mechanical vibration, and concentrate the ultrasonic energy on a small area, that is, the energy is collected. Also known as ultrasonic shift levers or ultrasonic concentrators.

Ultrasonic booster, as the name suggests, are functional components that match the amplitude of ultrasonic vibrations with ultrasonic transducers. Its main function is to change the amplitude of the transducer (generally increase), improve the vibration ratio, improve the efficiency, improve the mechanical quality factor, enhance the heat resistance, expand the temperature range, and prolong the service life of the transducer. The ultrasonic transducer adjusts the load matching between the transducer and the ultrasonic horn by installing a booster, which reduces the resonance impedance and makes it work at the resonant frequency to improve the electro-acoustic conversion efficiency. Reduces the heat generation of the ultrasonic transducer and improves the service life.

FAQ:

1. What’s the warranty of your transducer and equipment.

Our warranty is one year for both transducer and equipment, but we can supply you Components free even out of warranty.

2. What’s frequency transducer you supply?

We can supply transducer from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your transducer?

Under correct working environment, our transducer can work 5~10 years

4. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

5. Does your products exported before?

Yes, our transducer exported to USA,south America, EUROPE, Middle East, and Russia for many years.

6. Do you supply sample for test?

Yes, you can order on sample from our company first , we will return you the sample cost when you order in the future.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. how to customize transducer ?

For two ways for customize transducer, first way, you supply me sample , I will customize depending on your sample. Second, you give us all parameter and drawing , we can customize depending on your information.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

FAQ:

1. What’s the warranty of your transducer and equipment.

Our warranty is one year for both transducer and equipment, but we can supply you Components free even out of warranty.

2. What’s frequency transducer you supply?

We can supply transducer from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your transducer?

Under correct working environment, our transducer can work 5~10 years

4. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

5. Does your products exported before?

Yes, our transducer exported to USA,south America, EUROPE, Middle East, and Russia for many years.

6. Do you supply sample for test?

Yes, you can order on sample from our company first , we will return you the sample cost when you order in the future.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. how to customize transducer ?

For two ways for customize transducer, first way, you supply me sample , I will customize depending on your sample. Second, you give us all parameter and drawing , we can customize depending on your information.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

The service life of the welding horn is determined by two aspects: 1. Material, 2. Process Material: Ultrasonic welding requires good flexibility of the metal material (the mechanical loss during the sound wave transmission process is small).

Good ultrasonic welding horn material is one of the main reasons to ensure the effect of ultrasonic mold life on the welding product. The process of mold completion is complicated. Therefore, it is not only the design of the mold engineer that the material must be carefully selected, but also the material that the product requires to be used to avoid inadvertent influence on its timeliness and quality.

The characteristics of the various materials are now outlined as follows:

1, 7075T651: used in vibration system and Horn manufacturing, the material has extremely high mechanical yield strength, high hardness, ultrasonic welding horn, strong thermal conductivity, is an ideal ultrasonic mold manufacturing material;

2, 2024T651: generally used and manufactured by HORN, good enthalpy, strong thermal conductivity, moderate hardness, used for general plastic products.

3, 6061T651: used in the production of HORN with lower output, good 轫, soft quality.

It is used for continuous vibration, with high enthalpy, good heat conduction, high hardness and high cost.

Chinese material, used for ordinary aluminum processing, low heat conduction, high mechanical loss to ultrasonic, low cost.

The service life of the welding horn is determined by two aspects: 1. Material, 2. Process Material: Ultrasonic welding requires good flexibility of the metal material (the mechanical loss during the sound wave transmission process is small).

Good ultrasonic welding horn material is one of the main reasons to ensure the effect of ultrasonic mold life on the welding product. The process of mold completion is complicated. Therefore, it is not only the design of the mold engineer that the material must be carefully selected, but also the material that the product requires to be used to avoid inadvertent influence on its timeliness and quality.

The characteristics of the various materials are now outlined as follows:

1, 7075T651: used in vibration system and Horn manufacturing, the material has extremely high mechanical yield strength, high hardness, ultrasonic welding horn, strong thermal conductivity, is an ideal ultrasonic mold manufacturing material;

2, 2024T651: generally used and manufactured by HORN, good enthalpy, strong thermal conductivity, moderate hardness, used for general plastic products.

3, 6061T651: used in the production of HORN with lower output, good 轫, soft quality.

It is used for continuous vibration, with high enthalpy, good heat conduction, high hardness and high cost.

Chinese material, used for ordinary aluminum processing, low heat conduction, high mechanical loss to ultrasonic, low cost.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China