- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 842 Author: Site Editor Publish Time: 2019-07-20 Origin: Site

The difference between ultrasonic welding and laser welding

At present, the advantages and disadvantages of the welding process play a decisive role in the heat transfer of the flat-plate solar collector, while the domestic flat-panel solar water heater collector (heat collecting plate) is mainly welded with laser welding and ultrasonic welding, and the flat solar collector absorbs. The hot plate is mainly made of aluminum sheet and copper sheet, and the flow channel is basically made of copper tube. These two welding methods have their own advantages in practical application.

Laser welding VS ultrasonic welding

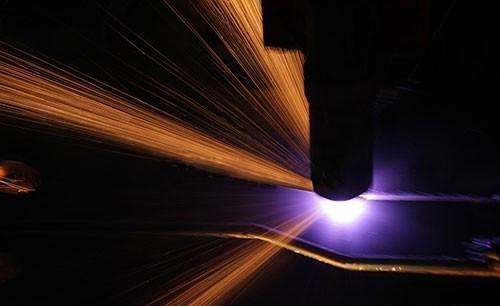

Laser technology is a beam that uses a polarizer to reflect the laser beam to concentrate it in the focusing device to generate huge energy. The laser focus emitted by the pulse reaches thousands of degrees Celsius, and the metal material is melted and evaporated in a few milliseconds. An effect is to weld the solar collector core flow channel and the highly selective heat absorbing coating, and a solder joint is separated by 3 to 5 mm on the solar heat absorbing film layer.

Non-contact welding, which can be transported for a long distance before being highly concentrated to provide functions such as welding, cutting and heat treatment. Its advantage is that no pressure is required on the workpiece to be welded, and the overall deformation is small, and the surface of the heat absorbing coating can be damaged to a small extent. This is also an important reason for the public opinion-oriented laser welding in the industry is superior to ultrasonic welding, but the laser welding will change the physical structure of the welded object, the mechanical strength will be worse, and it has certain influence on the thermal conductivity. At present, domestic laser welding representative manufacturers include: Han's Laser, Liansheng Laser, Chutian Laser and other enterprises.

Ultrasonic welding is a high-density energy generated by ultrasonic high-frequency mechanical vibration, which causes plastic deformation on the surface of the workpiece and destroys the surface layer under pressure, so that the welded metal is physically connected at normal temperature. Although ultrasonic welding destroys about 3% of the film layer, it is relatively good in heat transfer efficiency because it is continuous non-melting welding. At the same time, ultrasonic welding has certain advantages in terms of material cost. Ultrasonic welding is suitable for thin products. The international mainstream flat copper products are generally between 0.12mm and 0.2mm. In order to consider the material cost, some enterprises now choose aluminum plates, and ultrasonic welding selects 0.2. -0.3mm.

Laser welding is suitable for thick materials. For example, the thickness of aluminum plate is generally 0.4mm, which results in higher material cost. In fact, the two welding techniques have their own advantages. Which welding equipment companies should use according to their actual conditions to choose a more appropriate one, rather than a general evaluation of the advantages and disadvantages of the two welding techniques.

Advantages of ultrasonic welding VS advantages of laser welding

The advantage of laser technology is that no welding is required on the workpiece to be welded, and the overall deformation is small, which can damage the surface of the heat absorbing coating to a minimum. However, laser welding also affects the physical structure change of the welded object, and the solder joint is frequently and frequently impacted by cold and heat. Leading to fracture, the strength is poor, which is especially fatal for the alternating effect of cold and heat caused by the intermittent operation of the flat panel collector.

The advantages of ultrasonic metal welding are that the welding material is not melted, the characteristics of the metal are not fragile, the welding time is short, the fusion strength is high, and the processing is close to cold state; however, the heat absorption layer is destroyed by about 3%, and the welded metal is not too thick (generally ≤ 5 mm) It is an advantage for flat-plate solar heat-absorbing plate welding, and because it is continuous non-melting welding, the heat transfer efficiency is relatively good. Some people have done the same test under the same conditions, the ultrasonic welding products have higher heat transfer efficiency than laser welding. About 3%.

Ultrasonic metal spot welding machine is used for similar welding of metal, and can carry out single-point and multi-point short strip welding on thin materials of copper, silver, aluminum and nickel non-ferrous metals. It can be widely applied to fuse lithium battery. Welding of various shapes such as the ear.

Ultrasonic metal spot welding machine adopts electronic program control, high power, high efficiency, automatic control, easy operation, built-in electronic protection circuit, safe to use, stable and reliable. The weldment has the characteristics of firm welding surface, high strength, subjective and environmental protection.

At present, the thickness of the copper plate of the mainstream flat products in the world is generally between 0.12mm and 0.2mm, and the wall thickness of the copper pipe is mostly 0.5mm. As the price of copper continues to rise, enterprises are increasingly considering the cost of materials. Aluminum plate, copper thermal conductivity is 390W / (m · K), aluminum thermal conductivity is 237W / (m · K), according to the basic formula of heat conduction Q = posture × A × △ T / L, the thickness of the aluminum plate reaches 1.65 times the copper plate (2mm~3mm) can achieve the same heat transfer rate.

Ultrasonic welding machines are suitable for welding relatively thin products, and laser welding will directly penetrate thin. Another important aspect is that the price of laser welding machines is several times higher than that of ultrasonic welding machines.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China