- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Frequency: | |

|---|---|

| Power: | |

| Application : | |

| Availability: | |

| Quantity: | |

3000M

Rps-sonic

3000M

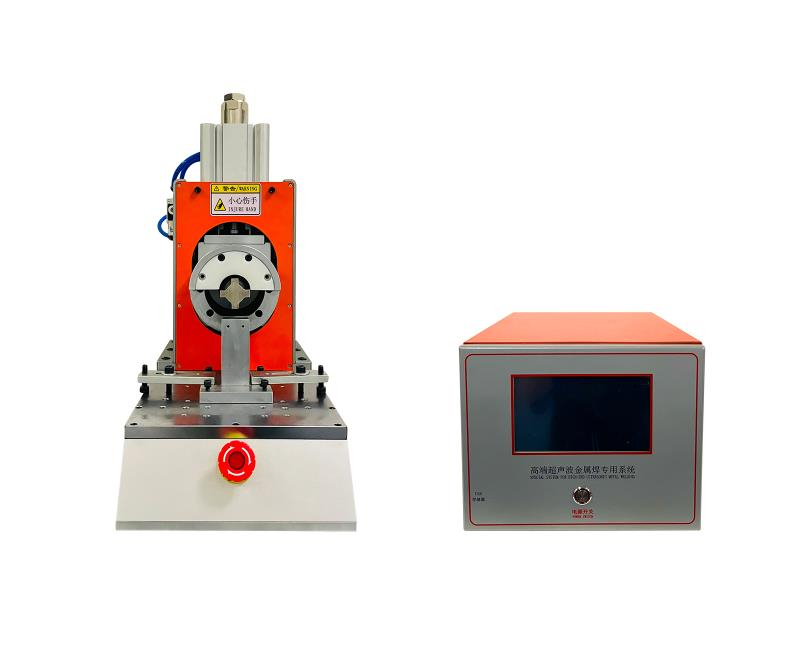

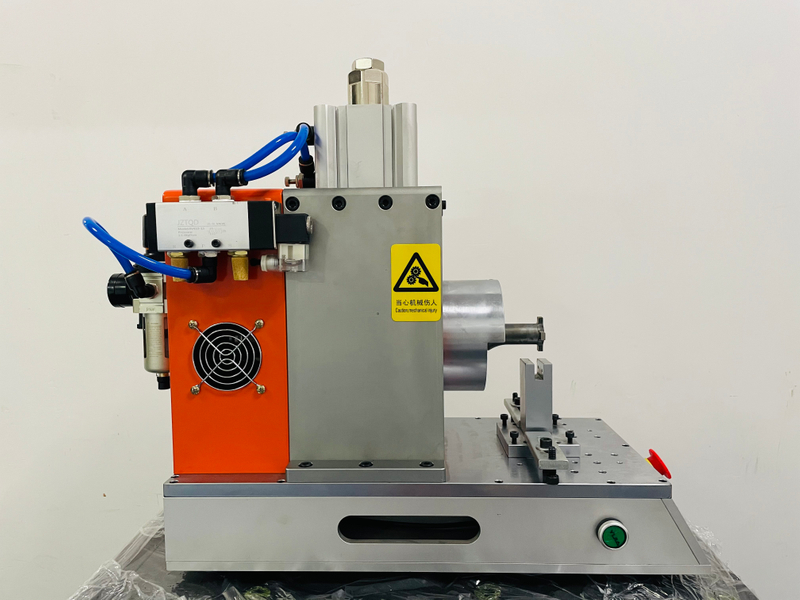

Introduction:

Ultrasonic welding machine with modes of time model and engry model, it can automatically track and display real-time frequency, with amplitude stepping function, welding amplitude range up to 10-100(1%accuracy). There is also amplitude compensation; welding quality management (time,energy mutual detection), including clear traceable welding records (operation statistics) to control your welding quality in real time. It also features transducer overload protection, mold impedance analysis and protection to protect your equipment. Powerful, high quality and high welding stability.

*Full range of modular design

*High-strength rigid structure

*Digital ultrasonic generator

*Maximum pressure 1000N

*4.3 inch color touch screen.

*Chinese and English use interface.

*Germany designed digital ultrasonic generator, which can accurately adjust and stabilize various parameters, can safely protect the control box.

*Electronic pressure measuring device.

*Precision electronic ruler for welding depth control with accuracy of +0.01mm.

*4 different trigger modes.

*5 different welding modes (time, energy, maximum power, relative position, absolute position welding mode).

*Welding parameter data storage.

*Ultrasonic amplitude adjustment 50%-100%.

*Ultrasonic frequency automatic tracking.

*Quality management function.

*Printer output function (optional).

| Σ3000M | 20Khz | 20Khz |

| Power | 2000W/3000W | 4000W/5000W |

| Pressure | 3000N | 3000N |

| Power Input | 2000W/10A 3000W/15A AC 220V +10% 50/60Hz | 4000W,5000W/15A AC 220V +10% 50/60Hz |

| Electric Box Size | 2000W/420mm×211mm×185mm 3000W/465mm×211mm×185mm | 465mm×211mm×185mm |

| Electric Box Weight | 10KG | 11.76KG |

| Machine Size | 747mm×467mm×581mm | 792mm×467mm×581mm |

| Machine Weight | 64.5KG | 66.2KG |

Introduction:

Ultrasonic welding machine with modes of time model and engry model, it can automatically track and display real-time frequency, with amplitude stepping function, welding amplitude range up to 10-100(1%accuracy). There is also amplitude compensation; welding quality management (time,energy mutual detection), including clear traceable welding records (operation statistics) to control your welding quality in real time. It also features transducer overload protection, mold impedance analysis and protection to protect your equipment. Powerful, high quality and high welding stability.

*Full range of modular design

*High-strength rigid structure

*Digital ultrasonic generator

*Maximum pressure 1000N

*4.3 inch color touch screen.

*Chinese and English use interface.

*Germany designed digital ultrasonic generator, which can accurately adjust and stabilize various parameters, can safely protect the control box.

*Electronic pressure measuring device.

*Precision electronic ruler for welding depth control with accuracy of +0.01mm.

*4 different trigger modes.

*5 different welding modes (time, energy, maximum power, relative position, absolute position welding mode).

*Welding parameter data storage.

*Ultrasonic amplitude adjustment 50%-100%.

*Ultrasonic frequency automatic tracking.

*Quality management function.

*Printer output function (optional).

| Σ3000M | 20Khz | 20Khz |

| Power | 2000W/3000W | 4000W/5000W |

| Pressure | 3000N | 3000N |

| Power Input | 2000W/10A 3000W/15A AC 220V +10% 50/60Hz | 4000W,5000W/15A AC 220V +10% 50/60Hz |

| Electric Box Size | 2000W/420mm×211mm×185mm 3000W/465mm×211mm×185mm | 465mm×211mm×185mm |

| Electric Box Weight | 10KG | 11.76KG |

| Machine Size | 747mm×467mm×581mm | 792mm×467mm×581mm |

| Machine Weight | 64.5KG | 66.2KG |

Rps-sonic, consisted with a couple of young people who love ultrasonic very much.The founding members of RPS-SONIC have an average degree of Bachelor's degree or above. They have been in the ultrasonic industry for more than 5 years and have rich experience in ultrasound. The company's business philosophy is: Do not blindly promote any product, find the right product for the customer. So before each order, we will confirm all the details, including application details, equipment conditions, equipment specific information.

Before year 2012, we only sale second branson / dukane / rinco / herrman/telsonic welding equipment , during these twenty year develop, we find, more and more people have problem with the core part of ultrasonic welding equipment -generator and transducer, so we decided to start our business of transducer and generator of our own transducer and generator. Many of the end user meet the transducer problem, they don’t know why transducer broken, and changing the expensive transducer one by one. Actually, one branson /dukane /rinco transducer can use 10~30 year, even the cheapest transducer can use about 5 years. So there must some reasons if your transducer broken in one year. That’s why we want build Rps-sonic, we need to help more end user to know more about transducer , to use ultrasonic equipment better, to save cost when meet problem.

Unreasonable operation may shorter the use-life of ultrasonic generator. So we have to make technical inquiry before operate ultrasonic welding machine. The key point of ultrasonic machine is resonance, only keep every part in resonance can make the system in best work environment.

We are committed to developing a more stable ultrasonic generator, which minimizes the failure rate of the box and escorts your production process.

Rps-sonic, consisted with a couple of young people who love ultrasonic very much.The founding members of RPS-SONIC have an average degree of Bachelor's degree or above. They have been in the ultrasonic industry for more than 5 years and have rich experience in ultrasound. The company's business philosophy is: Do not blindly promote any product, find the right product for the customer. So before each order, we will confirm all the details, including application details, equipment conditions, equipment specific information.

Before year 2012, we only sale second branson / dukane / rinco / herrman/telsonic welding equipment , during these twenty year develop, we find, more and more people have problem with the core part of ultrasonic welding equipment -generator and transducer, so we decided to start our business of transducer and generator of our own transducer and generator. Many of the end user meet the transducer problem, they don’t know why transducer broken, and changing the expensive transducer one by one. Actually, one branson /dukane /rinco transducer can use 10~30 year, even the cheapest transducer can use about 5 years. So there must some reasons if your transducer broken in one year. That’s why we want build Rps-sonic, we need to help more end user to know more about transducer , to use ultrasonic equipment better, to save cost when meet problem.

Unreasonable operation may shorter the use-life of ultrasonic generator. So we have to make technical inquiry before operate ultrasonic welding machine. The key point of ultrasonic machine is resonance, only keep every part in resonance can make the system in best work environment.

We are committed to developing a more stable ultrasonic generator, which minimizes the failure rate of the box and escorts your production process.

1. What’s the warranty of your generator

Our warranty is one year , but we can supply you Components free even out of warranty.

2. What’s frequency generator you supply?

We can supply generatorr from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

4. Does your products exported before?

Yes, our Generator exported to USA,south America, EUROPE, Middle East, and Russia for many years.

5. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

6. How to customize generator ?

You can buy the PCB board only, and you cuztomize the out box in your local place.

7. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

8. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

1. What’s the warranty of your generator

Our warranty is one year , but we can supply you Components free even out of warranty.

2. What’s frequency generator you supply?

We can supply generatorr from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

4. Does your products exported before?

Yes, our Generator exported to USA,south America, EUROPE, Middle East, and Russia for many years.

5. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

6. How to customize generator ?

You can buy the PCB board only, and you cuztomize the out box in your local place.

7. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

8. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China