- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasound atomization technology is an efficient and low-cost method for producing fine metal powders. The powders produced using this method have good sphericity, controllable particle size, and a narrow size distribution, making it a promising technology in the metal powder industry. Ultrasound m

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

Type of PumpsAccording to the working principle and structure of the pump, there are several types of pumps:

What is Diesel Water Emulsion?To best understand what a diesel water emulsion is, we first must discuss the process of emulsifying liquids. Chemically speaking, an emulsified liquid, also known as a dispersion, is a liquid in which distributed particles of one material are dispersed in another mater

Ultrasonic extraction, also known as sonication, is a powerful technique that harnesses the energy of high-frequency sound waves to extract valuable compounds from various natural sources. This non-invasive and environmentally friendly method has gained significant attention in recent years due to i

Ultrasonic emulsification results in significantly smaller droplets and better emulsion stability. Ultrasonic nano-emulsification is used to produce high-performance emulsions for high-performance materials, paints, coatings, food, pharma, and cosmetics. Organic and inorganic pigments are an importa

Ultrasonic spray coating system is a technique for forming thin films with specific functions or properties on the surface of optical glass. It utilizes ultrasonic waves to atomize liquid into fine droplets and uniformly spray them onto the surface of optical glass. This article introduces the princ

By Matthew Taylor, Associate Researcher & Writer at Save The Water™ | March 30, 2021 Not every water purification technology matches a given situation effectively. For example, their ability to remove some contaminants from water, their cost, and their capacity limit them. We need new technologies t

The use of ultrasonics is becoming increasingly important for the food industry.Ultrasound in Food Processing enables scientists, engineers andmanagers in food manufacturing to make informed choices about anew and important area of research and development. It will also be avaluable reference to peo

What is ultrasonic tinning?Ultrasonic tinning is a kind of welding method that does not use flux. The ultrasonic probe produces cavitation in the molten solder core through mechanical vibration at ultrasonic frequency, and removes the oxide film on the metal surface for smooth and clean tinning. Ult

Do you know? Every year, over 10 billion blood collection tubes and syringe barrels are produced and used worldwide, playing a crucial role in the diagnosis and treatment in the medical field. However, what you may not know is that the most critical step in the manufacturing process of these devices

Float glass is a widely used glass product in various fields. Its production process involves floating molten glass on a high-temperature tin bath to form a flat, smooth, and uniform glass ribbon. Float glass has advantages such as good optical properties, high transparency, and high surface quality

The application of ultrasonic in the sewing industry mainly reflects the two major functions of ultrasonic: welding and cutting. In 2019, for masks that are popular all over the world, ultrasound is a household name for applying these two functions to the fullest. The cutting and welding of velvet c

what's the ultrasonic ? what's the ultrasonic extractor technology? the essay will introduce the ultrasonic and ultrasonic extraction techolgy from many aspects.

Ultrasonic spraying, also known as ultrasonic spraying, is a spraying process using ultrasonic atomization technology. The sprayed material is first in a liquid state. The liquid can be a solution, sol, suspension, etc. The liquid coating is first atomized into fine particles by an ultrasonic atomiz

| Frequency: | |

|---|---|

| Capacity: | |

| Power: | |

| Condition: | |

| Availability: | |

| Quantity: | |

RPS-3820-4z

Rps-sonic

RPS-3820--4z

Ultrasonic generator transforms low-frequency alternating current into high-frequency alternating current, and transforms electric energy into mechanical energy through the transducer

When the welding head acts on the contact surface of thermoplastic, it will produce tens of thousands of high frequency vibrations per second

The high frequency vibration transmits ultrasonic energy to welding area , local high temperature is created due to mechanical force and friction between the plastic parts

Pressure lasts for a few seconds, ultrasonic welding making it solidify, forming a solid molecular chain and realizing welding

No solvents, adhesives or other auxiliary materials required

No pollution

Enviromental-friendly

Automatic frequency search, automatic frequency tracking, no need for manual adjustment

Ultrasonic amplitude is stepless and adjustable from 0% - 100% , intelligently matching of different product types

More than 300 welding records

Replace manual welding

Increase efficiency

Lower the cost

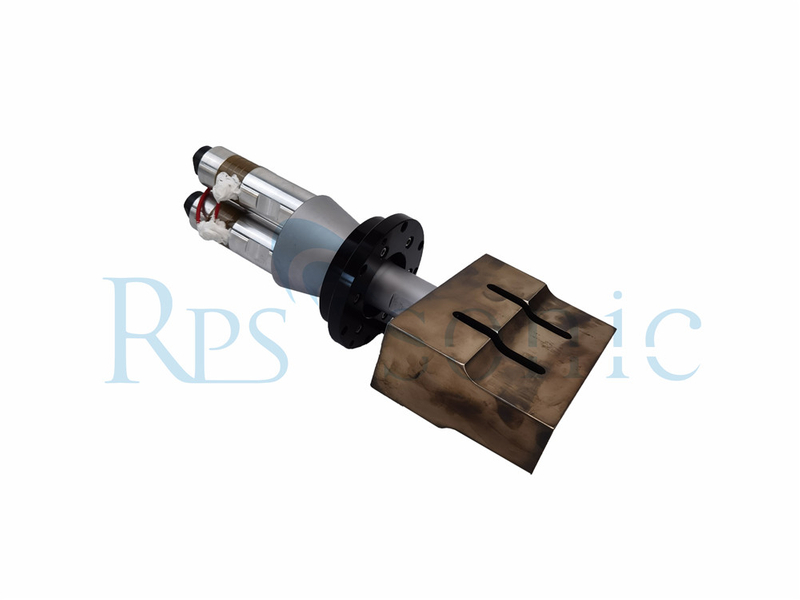

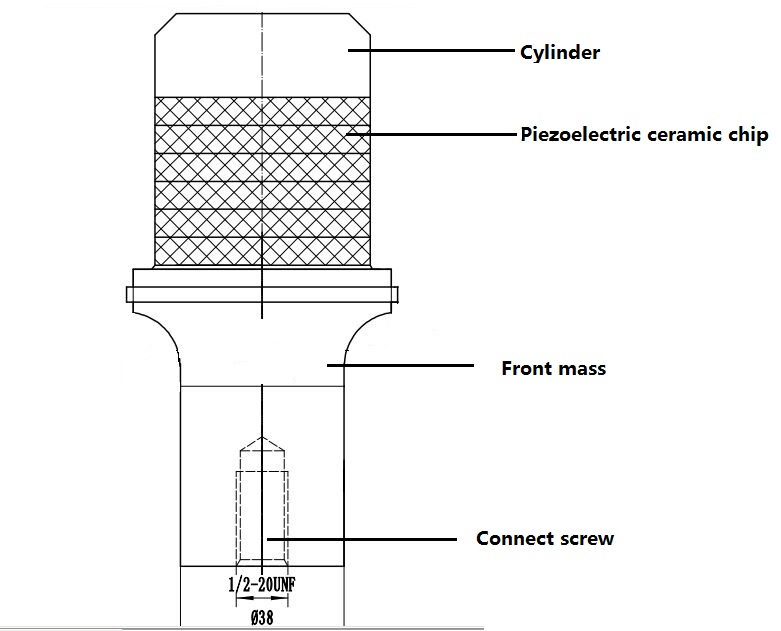

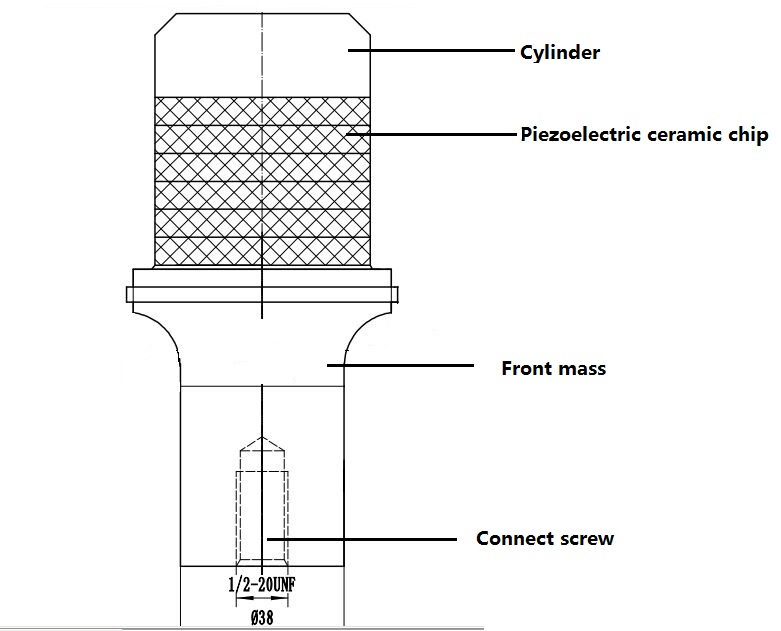

High Power Ultrasonic Transducers with Two Parallel Stacks for Welding

Item | Parameter |

Frequency | 14.5~15.1Khz |

Power | 3200W |

Impedance | 14 |

Capatance | 14000~16000pf |

Ultrasonic welding is used across variety of industries to join together thermoplastic materials. During ultrasonic welding, high frequency mechanical vibrations and compressive pressure are applied to the plastic materials. This creates intermolecular friction within the plastic which raises the temperature high enough to reach the melting point. During high volume production in manufacturing environments, the ultrasonic welding system component which fails most often is the transducer, which is responsible for creating the vibration. The transducer converts electrical energy into mechanical energy by means of a polarized piezoelectric PZT (lead zirconate titanate) polycrystalline ceramic material using high frequency voltage. The transducer is composed of round PZT disks attached to a titanium machined body by means of a central bolt. The bolt creates compressive pre-stress which prevents any tensile stresses within the brittle crystals during vibration and ensures perfect coupling between all components. The piezoelectric PZT crystals behave according to linear coupled electrical and mechanical equations. The transducer assembly is vibrated near the parallel resonant frequency to maximize efficiency and amplitude output.

Service and shipment

The Information You Want To Know about our professionals.

No MOQ: customers can order according to demand.

Regular terms of sale: FOB.

Export orders: generally shipped by AIR, urgent orders are specially treated according to customer needs.

Production cycle: different for each order, depending on the actual order product.

Payment method: 100% will be paid in one lump sum before delivery.

Ultrasonic generator transforms low-frequency alternating current into high-frequency alternating current, and transforms electric energy into mechanical energy through the transducer

When the welding head acts on the contact surface of thermoplastic, it will produce tens of thousands of high frequency vibrations per second

The high frequency vibration transmits ultrasonic energy to welding area , local high temperature is created due to mechanical force and friction between the plastic parts

Pressure lasts for a few seconds, ultrasonic welding making it solidify, forming a solid molecular chain and realizing welding

No solvents, adhesives or other auxiliary materials required

No pollution

Enviromental-friendly

Automatic frequency search, automatic frequency tracking, no need for manual adjustment

Ultrasonic amplitude is stepless and adjustable from 0% - 100% , intelligently matching of different product types

More than 300 welding records

Replace manual welding

Increase efficiency

Lower the cost

High Power Ultrasonic Transducers with Two Parallel Stacks for Welding

Item | Parameter |

Frequency | 14.5~15.1Khz |

Power | 3200W |

Impedance | 14 |

Capatance | 14000~16000pf |

Ultrasonic welding is used across variety of industries to join together thermoplastic materials. During ultrasonic welding, high frequency mechanical vibrations and compressive pressure are applied to the plastic materials. This creates intermolecular friction within the plastic which raises the temperature high enough to reach the melting point. During high volume production in manufacturing environments, the ultrasonic welding system component which fails most often is the transducer, which is responsible for creating the vibration. The transducer converts electrical energy into mechanical energy by means of a polarized piezoelectric PZT (lead zirconate titanate) polycrystalline ceramic material using high frequency voltage. The transducer is composed of round PZT disks attached to a titanium machined body by means of a central bolt. The bolt creates compressive pre-stress which prevents any tensile stresses within the brittle crystals during vibration and ensures perfect coupling between all components. The piezoelectric PZT crystals behave according to linear coupled electrical and mechanical equations. The transducer assembly is vibrated near the parallel resonant frequency to maximize efficiency and amplitude output.

Service and shipment

The Information You Want To Know about our professionals.

No MOQ: customers can order according to demand.

Regular terms of sale: FOB.

Export orders: generally shipped by AIR, urgent orders are specially treated according to customer needs.

Production cycle: different for each order, depending on the actual order product.

Payment method: 100% will be paid in one lump sum before delivery.

FAQ:

1. What’s the warranty of your transducer and equipment.

Our warranty is one year for both transducer and equipment, but we can supply you Components free even out of warranty.

2. What’s frequency transducer you supply?

We can supply transducer from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your transducer?

Under correct working environment, our transducer can work 5~10 years

4. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

5. Does your products exported before?

Yes, our transducer exported to USA,south America, EUROPE, Middle East, and Russia for many years.

6. Do you supply sample for test?

Yes, you can order on sample from our company first , we will return you the sample cost when you order in the future.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. how to customize transducer ?

For two ways for customize transducer, first way, you supply me sample , I will customize depending on your sample. Second, you give us all parameter and drawing , we can customize depending on your information.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

FAQ:

1. What’s the warranty of your transducer and equipment.

Our warranty is one year for both transducer and equipment, but we can supply you Components free even out of warranty.

2. What’s frequency transducer you supply?

We can supply transducer from 15Khz to 70Khz depending on your requirements or application.

3. What’s the using life of your transducer?

Under correct working environment, our transducer can work 5~10 years

4. What’s the using life of your generator?

Under correct working environment, our generator can work 8~10 years

5. Does your products exported before?

Yes, our transducer exported to USA,south America, EUROPE, Middle East, and Russia for many years.

6. Do you supply sample for test?

Yes, you can order on sample from our company first , we will return you the sample cost when you order in the future.

7. Do you supply OEM work?

Yes, welcome to ask for OEM cooperation , we have OEM produced for USA and German customer for many years, also hope to get more OEM order to enlarge our business.

8. how to customize transducer ?

For two ways for customize transducer, first way, you supply me sample , I will customize depending on your sample. Second, you give us all parameter and drawing , we can customize depending on your information.

9. Can you generator connect to PC, PLC or internet .

Yes, we have different version generator, it can connect to PC. PLC, even internet.Also the price different.

10. What we can get if the transducer/equipment broken during the warranty?

All our transducer and generator tested at least 48 hours before shipment , so we have confidence to our equipment. Of course, We will send you new transducer/ equipment if it broken in the warranty. At the same time, we need to find the problem , why it broken so fast.

The upside-down trumpet type BRANSON TYPE (Larger amplitude and bigger output power, high-sound intensity and high-power density application) | |||||||||||

Item No. | Connect screw (Size) | Ceramic diameter (mm) | Quantity of Ceramic (pc) | Resonance frequency (khz) | Resistance (Ω) | Capacitance | Input power (W) | Max. Amplitude (um) | |||

Yellow | Grey | Black | |||||||||

7015-4D | M20 X 1.5 | 70 | 4 | 15 | 15 | 12500-14000 | / | 17000-19000 | 2600 | 11 | |

6015-4D | M18 X 1.5 | 60 | 4 | 15 | 15 | 9000-10000 | 10000-11000 | / | 2200 | 11 | |

6015-6D | 1/2-20UNF | 60 | 6 | 15 | 15 | 19000-20500 | / | 23000-25000 | 2600 | 11 | |

5015-6D | 1/2-20UNF | 50 | 6 | 15 | 15 | 17000-19000 | / | 23000-25000 | 2000 | 11 | |

5020-4DS | 1/2-20UNF | 50 | 4 | 20 | 15 | 11000-12000 | 12000-13500 | / | 1300 | 8 | |

5020-4D | 1/2-20UNF | 50 | 4 | 20 | 15 | 11000-12000 | 12000-13500 | 14500-16000 | 1500 | 8 | |

5020-6D | 1/2-20UNF | 50 | 6 | 20 | 15 | 19000-21000 | / | 22500-25000 | 2000 | 10 | |

4020-6D | 1/2-20UNF | 40 | 6 | 20 | 15 | 13500-15000 | / | / | 1500 | 10 | |

4020-4D | 1/2-20UNF | 40 | 4 | 20 | 15 | 8500-9300/9500-10500 | 10000-11000 | 10500-11500 | 900 | 8 | |

3020-6D | 3/8-24UNF | 30 | 6 | 20 | 15 | 8000-9000 | / | / | 600 | 9 | |

3030-4D | M8 or M8 X 1 | 30 | 4 | 30 | 20 | / | 6200-6900 | / | 800 | 5 | |

3535-2D | M8 X 1 | 35 | 2 | 35 | 25 | / | / | 4500-5000 | 600 | 9 | |

3535-4D | M8 X 1 | 35 | 4 | 35 | 20 | 6600-7400 | / | 9000-10000 | 1000 | 4 | |

3035-4D | 1/2-20UNF | 30 | 4 | 35 | 20 | 5500-6200 | / | 9200-10200 | 800 | 4 | |

2535-4D | M8 | 25 | 4 | 35 | 25 | 3900-4300 | / | / | 500 | 4 | |

3040-2D | M8 | 30 | 2 | 40 | 30 | / | 3400-3800 | / | 500 | 2 | |

2540-4D | M8 | 25 | 4 | 40 | 30 | 4500-5300 | / | / | 500 | 3 | |

2040-2D | M8 | 20 | 2 | 40 | 40 | 1100-1300 | 1150-1350 | / | 300 | 2 | |

The upside-down trumpet type BRANSON TYPE (Larger amplitude and bigger output power, high-sound intensity and high-power density application) | |||||||||||

Item No. | Connect screw (Size) | Ceramic diameter (mm) | Quantity of Ceramic (pc) | Resonance frequency (khz) | Resistance (Ω) | Capacitance | Input power (W) | Max. Amplitude (um) | |||

Yellow | Grey | Black | |||||||||

7015-4D | M20 X 1.5 | 70 | 4 | 15 | 15 | 12500-14000 | / | 17000-19000 | 2600 | 11 | |

6015-4D | M18 X 1.5 | 60 | 4 | 15 | 15 | 9000-10000 | 10000-11000 | / | 2200 | 11 | |

6015-6D | 1/2-20UNF | 60 | 6 | 15 | 15 | 19000-20500 | / | 23000-25000 | 2600 | 11 | |

5015-6D | 1/2-20UNF | 50 | 6 | 15 | 15 | 17000-19000 | / | 23000-25000 | 2000 | 11 | |

5020-4DS | 1/2-20UNF | 50 | 4 | 20 | 15 | 11000-12000 | 12000-13500 | / | 1300 | 8 | |

5020-4D | 1/2-20UNF | 50 | 4 | 20 | 15 | 11000-12000 | 12000-13500 | 14500-16000 | 1500 | 8 | |

5020-6D | 1/2-20UNF | 50 | 6 | 20 | 15 | 19000-21000 | / | 22500-25000 | 2000 | 10 | |

4020-6D | 1/2-20UNF | 40 | 6 | 20 | 15 | 13500-15000 | / | / | 1500 | 10 | |

4020-4D | 1/2-20UNF | 40 | 4 | 20 | 15 | 8500-9300/9500-10500 | 10000-11000 | 10500-11500 | 900 | 8 | |

3020-6D | 3/8-24UNF | 30 | 6 | 20 | 15 | 8000-9000 | / | / | 600 | 9 | |

3030-4D | M8 or M8 X 1 | 30 | 4 | 30 | 20 | / | 6200-6900 | / | 800 | 5 | |

3535-2D | M8 X 1 | 35 | 2 | 35 | 25 | / | / | 4500-5000 | 600 | 9 | |

3535-4D | M8 X 1 | 35 | 4 | 35 | 20 | 6600-7400 | / | 9000-10000 | 1000 | 4 | |

3035-4D | 1/2-20UNF | 30 | 4 | 35 | 20 | 5500-6200 | / | 9200-10200 | 800 | 4 | |

2535-4D | M8 | 25 | 4 | 35 | 25 | 3900-4300 | / | / | 500 | 4 | |

3040-2D | M8 | 30 | 2 | 40 | 30 | / | 3400-3800 | / | 500 | 2 | |

2540-4D | M8 | 25 | 4 | 40 | 30 | 4500-5300 | / | / | 500 | 3 | |

2040-2D | M8 | 20 | 2 | 40 | 40 | 1100-1300 | 1150-1350 | / | 300 | 2 | |

Ms. Yvonne

sales@xingultrasonic.com

0086-15658151051

Room 1103B, Nature business building , NO.1160 GongWang Road ,FuYang, Hangzhou,Zhejiang,China